Bridging the Mid-Mile Visibility Gap: Real-Time EDI and API Solutions for Supply Chain Transparency in 2025

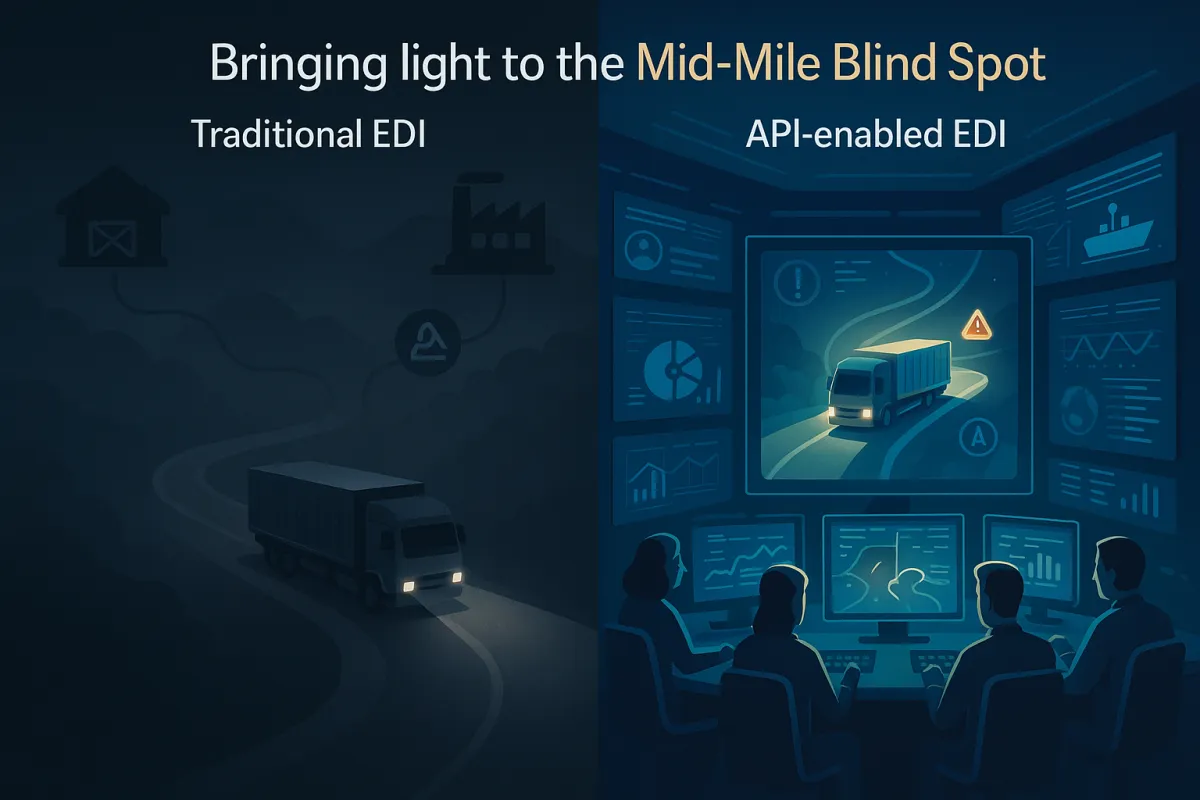

Supply chains continue to evolve rapidly, but one gap remains stubbornly persistent: the mid-mile visibility problem. Despite improvements in tracking solutions, 37% of companies still struggle to monitor shipments in transit, leaving critical blind spots between warehouse departure and final delivery. In 2025, it was reported that global supply chain disruptions in 2024 led companies to incur financial losses averaging around 8% of their annual revenues. Many of these losses could have been prevented with better real-time visibility and response capabilities.

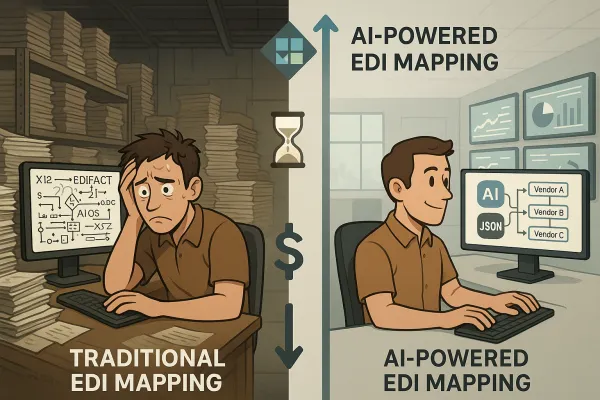

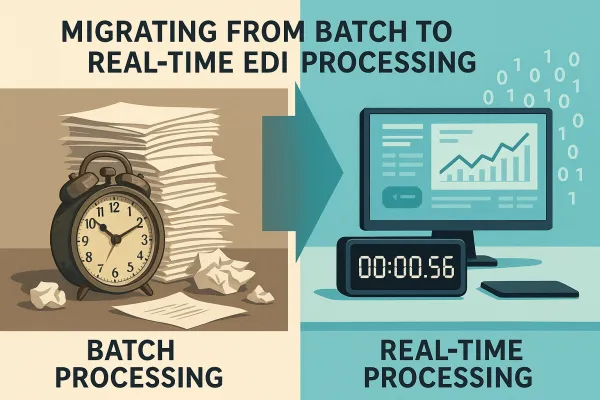

Traditional batch-processing EDI systems, while reliable for document exchange, can't keep pace with today's demands for instant visibility and exception management. The shift toward real-time data integration through API-enabled EDI architectures offers a practical solution—but implementation requires careful planning to balance legacy system requirements with modern visibility needs.

The Mid-Mile Crisis: Why Traditional EDI Falls Short in Supply Chain Visibility

The mid-mile represents the most vulnerable segment of the supply chain journey. Tive's report highlights that first-mile and last-mile tracking have seen progress, but the mid-mile remains a critical blind spot. The mid-mile stage often involves multiple handoffs and long transit times, making shipments vulnerable to delays, damage and theft.

Legacy EDI systems create specific challenges during this critical phase. EDI transactions are typically asynchronous, therefore the system is only updated at certain times and cannot provide live data. When a shipment moves through multiple carriers or consolidation points, traditional EDI's batch processing creates information delays that can stretch from hours to entire business days.

Consider what happens when a manufacturer uses SAP Transportation Management with standard EDI connectivity. The system receives carrier acknowledgments through EDI 990 responses and tracking updates via EDI 214 messages, but these updates arrive on predetermined schedules—often every few hours. If a temperature-sensitive pharmaceutical shipment experiences cooling system failure during mid-mile transit, the delay in receiving this information can mean the difference between saving a $50,000 shipment and writing it off as a total loss.

One of the more concerning findings unearthed in its fourth annual State of Visibility report is that three in five (60%) businesses only discover shipment damage after delivery or not at all. This reactive discovery model fundamentally undermines supply chain resilience.

Oracle Transportation Management users face similar challenges. The system's robust planning capabilities become less effective when real-time data feeds are limited to batch EDI transmissions. Multi-modal shipments moving through ocean, rail, and truck segments often lose visibility during handoff points, where different carriers use incompatible EDI timing schedules.

Real-Time Data Requirements: What Modern Supply Chains Actually Need

The business case for real-time visibility extends beyond operational convenience—it's become a competitive necessity. The latest McKinsey Global Supply Chain Leader Survey suggests that problems like these remain the norm, not the exception, with nine in ten respondents saying they have encountered supply chain challenges in 2024.

Modern supply chains require specific data points at precise moments. Exception alerts must arrive within minutes, not hours. Temperature deviations, security breaches, or route changes need immediate notification to enable corrective action. However, despite this growth, many businesses still lack the real-time updates needed to respond to shipment risks. Simply having tracking data is not enough—companies need the right data at the right time to make informed decisions that prevent costly disruptions.

The technology infrastructure exists to support these requirements. AI adoption in supply chain operations has risen from 35% to 45%, helping companies optimise inventory, forecast demand and mitigate risks. Meanwhile, IoT-powered tracking is now used by 60% of companies, up from 55% in 2024. However, the integration layer between these advanced sensors and enterprise systems often relies on outdated EDI architectures.

Companies need three critical capabilities that traditional EDI struggles to provide: event-driven notifications that trigger within seconds of incidents, bidirectional data flows that allow real-time corrections and interventions, and dynamic routing of information based on shipment characteristics and risk profiles.

In 2024 alone, 80% of organizations faced supply chain disruptions, many experiencing not just one but multiple breakdowns. The financial impact of these disruptions amplifies when response times are measured in hours rather than minutes.

API-First EDI Integration: The Technical Solution

API-enabled EDI integration offers a hybrid approach that preserves existing EDI investments while adding real-time capabilities. Instead of replacing EDI entirely, this architecture uses APIs to accelerate critical data flows while maintaining EDI for bulk document processing.

APIs transmit data in milliseconds. This allows a transportation management system (TMS) to run on real-time data, whether you're getting tracking updates, building loads or getting spot quotes. The key lies in selective implementation—using APIs for time-sensitive data like exception alerts and GPS coordinates, while maintaining EDI for standard documents like invoices and proof of delivery.

Event-driven architecture becomes the foundation of this approach. When a shipment sensor detects a temperature spike, the API immediately pushes this data to all relevant systems simultaneously. The TMS receives the alert, the customer portal updates the shipment status, and automated systems can trigger corrective actions like rerouting or expedited handling.

Webhook implementations provide another crucial component. Rather than polling systems for updates, webhooks push notifications to subscribing applications the moment events occur. A shipment departure from a distribution center can trigger immediate notifications to customer service systems, carrier portals, and downstream logistics partners.

Modern transportation platforms like Cargoson, alongside established solutions like MercuryGate and Descartes MacroPoint, demonstrate this hybrid approach effectively. These platforms maintain EDI connectivity for traditional trading partner requirements while offering API access for real-time data integration with modern applications.

Implementation Strategy: Building Your Real-Time Visibility Stack

Successful implementation requires a phased approach that minimizes disruption while maximizing visibility gains. Start with high-impact, low-risk integrations before expanding to more complex scenarios.

Phase one focuses on exception management. Implement API connections for critical alerts—temperature deviations, security breaches, delivery delays beyond predetermined thresholds. These integrations provide immediate value while requiring minimal changes to existing EDI workflows. Integration through APIs is generally less complex than EDI integrations. EDI integrations may take several months, whereas, API integrations can take a matter of weeks, if not days.

Phase two addresses real-time tracking integration with TMS platforms. Manhattan Active, Blue Yonder, and SAP Extended Warehouse Management all support hybrid EDI-API architectures. The integration allows these systems to receive standard EDI documents for routine transactions while using APIs for time-sensitive updates.

Data standardization becomes critical during implementation. EDI uses structured formats like EDIFACT D.01B or X12 standards, while APIs typically exchange JSON or XML data. Transformation layers must handle format conversion without data loss or latency introduction. Modern integration platforms provide pre-built transformations for common EDI-to-API conversions.

Carrier connectivity platforms like Cargoson offer pre-configured integrations with hundreds of carriers, supporting both EDI and API connections. This eliminates the need to negotiate separate technical integrations with each carrier partner, significantly reducing implementation complexity.

Overcoming Common Integration Challenges

Security represents the most significant implementation challenge. API, because it's software dependent on the web and connects to many of your systems, may be more susceptible to hacking and data breaches than EDI. However, modern API security frameworks provide robust protection through OAuth 2.0 authentication, TLS encryption, and rate limiting.

EDI's inherent security advantages include point-to-point connections and established encryption protocols. EDI transmissions are encrypted, making it difficult for unauthorized individuals to access them. The hybrid approach maintains these security benefits for sensitive documents while using API connections for real-time data that requires broader accessibility.

Data format compatibility requires careful planning. Legacy ERP systems often struggle with the volume and frequency of real-time data updates. Implementing message queuing systems and data buffering prevents API data streams from overwhelming backend systems not designed for real-time processing.

Partner onboarding complexity increases with hybrid architectures. Each trading partner may have different capabilities—some supporting only EDI, others offering API connectivity, and some requiring both for different transaction types. A centralized integration platform that abstracts these differences simplifies partner management significantly.

Change management becomes crucial for successful adoption. Operations teams accustomed to batch processing schedules must adapt to real-time alert management. Training programs should focus on exception handling procedures and the use of real-time dashboards for proactive decision-making.

Measuring Success: KPIs for Real-Time Visibility Programs

Transit visibility percentage measures the most fundamental improvement. Calculate the percentage of shipments with continuous location and status visibility throughout their journey. Industry-leading companies achieve 95%+ visibility rates, compared to 60-70% for organizations relying solely on traditional EDI.

Exception resolution time provides another critical metric. Measure the time between exception detection and corrective action initiation. Real-time systems typically reduce resolution times from hours to minutes, preventing minor issues from escalating into major disruptions.

Data accuracy improvements become evident through reduced discrepancy rates between actual and reported shipment statuses. Real-time updates eliminate the lag-induced inaccuracies common in batch processing systems.

Cost impact analysis should include both hard savings (reduced expedited shipping costs, lower inventory holding costs) and soft benefits (improved customer satisfaction, enhanced operational flexibility). Companies that function in real-time enjoy 97% greater profits and 62% faster growth than their industry peers.

Customer satisfaction metrics often show the most dramatic improvements. On-time delivery rates, proactive communication effectiveness, and customer portal engagement typically increase significantly when real-time visibility capabilities are implemented.

Platform performance metrics matter for technical success measurement. API response times, system uptime percentages, and integration error rates provide operational visibility into the infrastructure supporting real-time capabilities.

Future-Proofing Your Integration Strategy

IoT integration represents the next frontier for supply chain visibility. Smart sensors, GPS trackers, and environmental monitors generate massive data streams that require real-time processing. API-first architectures provide the foundation for incorporating these technologies without rebuilding entire integration infrastructures.

AI-driven exception handling will transform reactive visibility into predictive intelligence. Machine learning algorithms analyzing real-time data streams can predict potential disruptions before they occur, enabling preemptive responses that prevent issues entirely.

Carrier requirements continue evolving toward real-time expectations. Major carriers are implementing API-first strategies for customer interactions, making real-time integration capabilities increasingly necessary for competitive service levels.

Regulatory compliance requirements are also driving real-time data needs. Environmental reporting, customs declarations, and safety monitoring increasingly require continuous data streams rather than periodic batch submissions.

Building scalable architectures now prevents costly rebuilds later. Modern platforms like Cargoson, alongside traditional solutions like E2open and Oracle Transportation Management, provide the flexibility to adapt to emerging requirements while maintaining compatibility with existing EDI partners.

The companies that successfully bridge the mid-mile visibility gap will be those that treat real-time integration as a strategic capability rather than a technical project. The hybrid EDI-API approach provides a practical path forward—preserving existing investments while building the foundation for next-generation supply chain intelligence.