Real-Time EDI Implementation: The Complete Performance Optimization Guide for Eliminating Supply Chain Bottlenecks in 2025

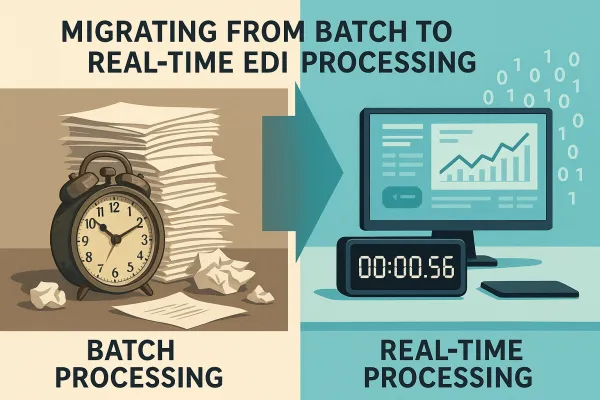

While most companies still batch process their EDI transactions overnight, real-time EDI processing can handle transactions in minutes rather than days or weeks. Supply chains equipped with real-time tracking systems and integrated platforms provide instant insights, with EDI systems playing a crucial role in aggregating and distributing data across partners. For supply chain professionals managing 100+ trading partners, this shift from batch to real-time processing represents a fundamental change in how quickly you can respond to disruptions.

Why Real-Time EDI Processing Eliminates Critical Supply Chain Bottlenecks

Traditional batch EDI creates decision delays that compound throughout your supply chain. When real-time data exchange is implemented, key players like suppliers, manufacturers, distributors and retailers receive updates about inventory levels, shipping schedules and payment status promptly, reducing lead times and improving inventory management. The difference becomes obvious during peak seasons or disruptions when you need immediate visibility.

High-volume transactions complete instantly with EDI, allowing businesses to shorten processing cycles, reduce lead times, and increase overall supply chain agility. Faster order fulfillment and quicker payments improve cash flow. Consider a manufacturer dealing with a supplier quality issue. With traditional batch processing, you might discover the problem 24 hours after shipment. Real-time EDI alerts you within minutes, allowing immediate action to prevent downstream impacts.

With EDI, businesses can process orders, invoices, and other transactions in real-time, ensuring goods move rapidly through the supply chain and enabling quicker responses to market demands. This speed advantage becomes especially pronounced when coordinating with multiple suppliers across different time zones.

Technical Infrastructure Requirements for Real-Time EDI Processing

Your current EDI setup likely wasn't designed for real-time processing. Cloud-native platforms promise scalability, flexibility, and real-time data processing while seamlessly integrating with other cloud services. Unlike traditional on-premise EDI solutions that depend on scheduled batch windows, real-time systems require persistent connections and immediate processing capabilities.

API-driven integrations enable real-time communication crucial for accurate and timely data transmission, using APIs to enable real-time EDI transactions that enhance transparency and responsiveness across supply chain networks. This hybrid approach addresses a key challenge: many of your existing trading partners still use traditional EDI formats, while newer partners prefer API-based connections.

Essential Infrastructure Components

EDI transactions sync in real-time with inventory, finance, and supply chain data, but this requires structured data formats and reliable communication protocols. Your infrastructure needs to handle EDIFACT, X12, and API protocols simultaneously. EDIFACT, used by companies like DSV, Maersk, and DB Schenker, is a very old standard with file exchange-based connections that require generating physical files and transmitting over FTP with cumbersome error feedback.

Modern solutions like Cargoson, TrueCommerce, and Cleo handle these protocol differences transparently. Cargoson offers direct API/EDI integrations with carriers across all transport modes, building true API/EDI connections rather than just accounts in software. This eliminates the technical complexity while maintaining compatibility with your existing partner network.

Step-by-Step Real-Time EDI Implementation Framework

Start by assessing which processes cause the most delays in your current setup. Assess the compatibility of your current systems with EDI technology, as many modern ERP systems have EDI capabilities built in, but legacy systems might require upgrades or middleware. This assessment prevents costly mistakes during implementation.

Your implementation timeline depends heavily on system complexity and partner requirements. Setup time varies based on carrier integrations, ERP integrations, and price lists, but typically takes 1-2 weeks when necessary information is provided accurately and carrier integrations are established. However, this assumes your data is clean and your current systems can handle real-time processing loads.

FreightPOP offers 1,500+ integrations with ERPs, carriers, and more, providing seamless integration with existing ERP, WMS, and eComm systems while maintaining real-time connections to carriers and rate marketplaces. Similarly, other platforms like Oracle TM and SAP TM provide enterprise-level real-time capabilities, though implementation complexity varies significantly.

Data Mapping and Integration Planning

Real-time processing demands precise data mapping between systems. API connections allow systems like TMS, WMS, ERP, load boards, tracking software, and carrier systems to connect seamlessly. The challenge lies in maintaining data consistency across multiple integration points without creating bottlenecks.

Pre-built mapping templates speed deployment, but customization remains necessary for most implementations. API documentations are required for integration with existing ERP or eCommerce systems, and carrier/freight forwarder integrations must link to their e-environments or set up corresponding emails and dedicated contacts. This preparation work prevents delays during go-live.

Overcoming Common Real-Time EDI Integration Challenges

The biggest challenge isn't technical complexity but managing disruptions during migration. Legacy EDI systems often rely on rigid, point-to-point integrations that are difficult to scale, with traditional EDI depending on batch processing that restricts data transfer and can create compatibility issues with internal systems. Companies often underestimate the impact on daily operations.

Partner onboarding represents another significant bottleneck. API is newer technology than EDI with less popularity, but freight brokers will benefit most from TMS systems utilizing both API and EDI integrations. This hybrid approach addresses the reality that your partner network uses mixed technologies.

Solutions providers handle this differently. FreightPOP includes new carrier integrations typically without additional charge, while others charge per connection. Cargoson and similar platforms focus on reducing onboarding time through standardized connection processes.

Preventing System Downtime During Migrations

Over 85% of global supply chain transactions are still powered by EDI, making system availability critical during transitions. The risk isn't just technical failure but business disruption when half your revenue flows through EDI connections. Strong emphasis on hands-on support ensures users transition smoothly, with dedicated operational teams ready to assist during the initial challenging weeks, including support teams, video tutorials, and feedback sessions.

Staging environments that mirror production setups allow thorough testing before cutover. Organizations increasingly turn to managed services and cloud-based tools to streamline EDI operations, reduce silos, and improve integration and transparency. This managed approach reduces internal IT burden while maintaining control over business processes.

Performance Monitoring and Optimization for Real-Time EDI

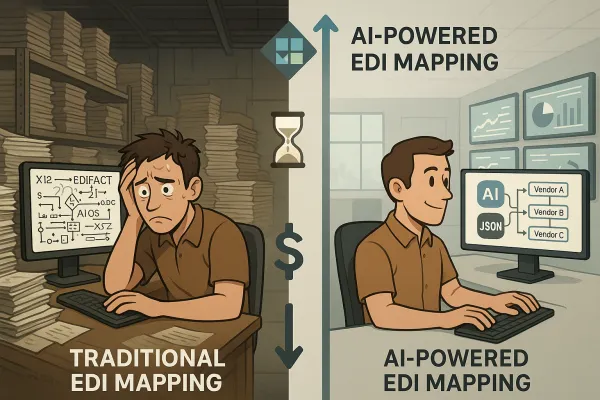

AI-powered EDI solutions offer enhanced control and visibility, allowing businesses to monitor transactions in real-time, track order status, and gain comprehensive insights into supply chain activities for prompt issue response and continuous improvement. However, monitoring real-time EDI requires different approaches than batch processing.

Traditional EDI monitoring focuses on batch success rates and error logs reviewed periodically. Real-time processing demands instant notifications and automated exception handling. AI can automate exception handling by identifying and resolving errors without human intervention, accelerating resolution while freeing IT staff for strategic tasks.

Key benefits include immediate access to critical data reducing delays, enhanced inventory control with real-time stock updates, faster order processing and delivery times, and improved customer satisfaction due to timely fulfillment. These metrics require dashboard systems that update continuously rather than daily or weekly reports.

Measuring ROI and Business Impact

EDI offers error reduction by eliminating manual data entry, faster communication enabling real-time transmission and decision-making, inventory optimization with accurate information, and cost reduction through process automation. Quantifying these benefits requires tracking specific metrics before and after implementation.

Real-time data exchange enables quick responses to shifting market demands and supply chain disruptions, while enhanced supply chain visibility supports better decision-making and collaboration. Companies typically see immediate improvements in order accuracy and processing speed, with inventory optimization benefits appearing over several months.

AI integration brings increased efficiency through automation, enhanced accuracy via data quality improvements, and cost savings by optimizing supply chain processes. The challenge lies in measuring these soft benefits against hard implementation costs.

Industry-Specific Benefits and Use Cases

Manufacturing companies often see the most dramatic improvements from real-time EDI, particularly in just-in-time inventory management. With real-time data from EDI, businesses optimize inventory levels by matching supply with demand, enabling just-in-time practices that reduce warehousing costs while receiving real-time stock updates from suppliers.

Retail operations benefit from instant inventory synchronization across multiple channels. E-commerce retailers use APIs to sync inventory levels between web platforms, warehouses and third-party retailers in real-time to avoid supply issues. This capability prevents overselling while maintaining optimal stock levels.

Healthcare and pharmaceutical companies require real-time visibility for regulatory compliance and patient safety. Blockchain technology adoption across supply chains, particularly with perishable food and pharmaceuticals, provides immutable records and real-time tracking aligned with EDI's data accuracy and security goals.

The implementation path varies by company size and complexity, but the fundamental requirement remains consistent: real-time EDI processing transforms reactive supply chain management into proactive optimization. By integrating EDI with key business systems, companies gain real-time insights, optimize operations, and improve overall performance as a critical step toward digital transformation.