The Complete EDI Hyperautomation Implementation Guide: How to Achieve Measurable ROI from AI-Powered Supply Chain Automation in 2025

Most EDI managers understand traditional automation: artificial intelligence (AI), machine learning (ML) and robotic process automation (RPA) to automate independent business functions in their supply chain operations. But in 2025, the conversation shifts to EDI hyperautomation—a comprehensive approach that delivers measurable ROI when implemented correctly. After years of pilots and proof-of-concepts, companies are finally seeing real results.

The data tells a sobering story: only 26% of companies have developed the necessary set of capabilities to move beyond proofs of concept and generate tangible value from their AI initiatives, according to recent BCG research. But successful EDI hyperautomation implementations are breaking through this barrier, combining traditional EDI workflows with intelligent automation to achieve substantial operational improvements.

Understanding EDI Hyperautomation: Beyond Traditional Rule-Based Automation

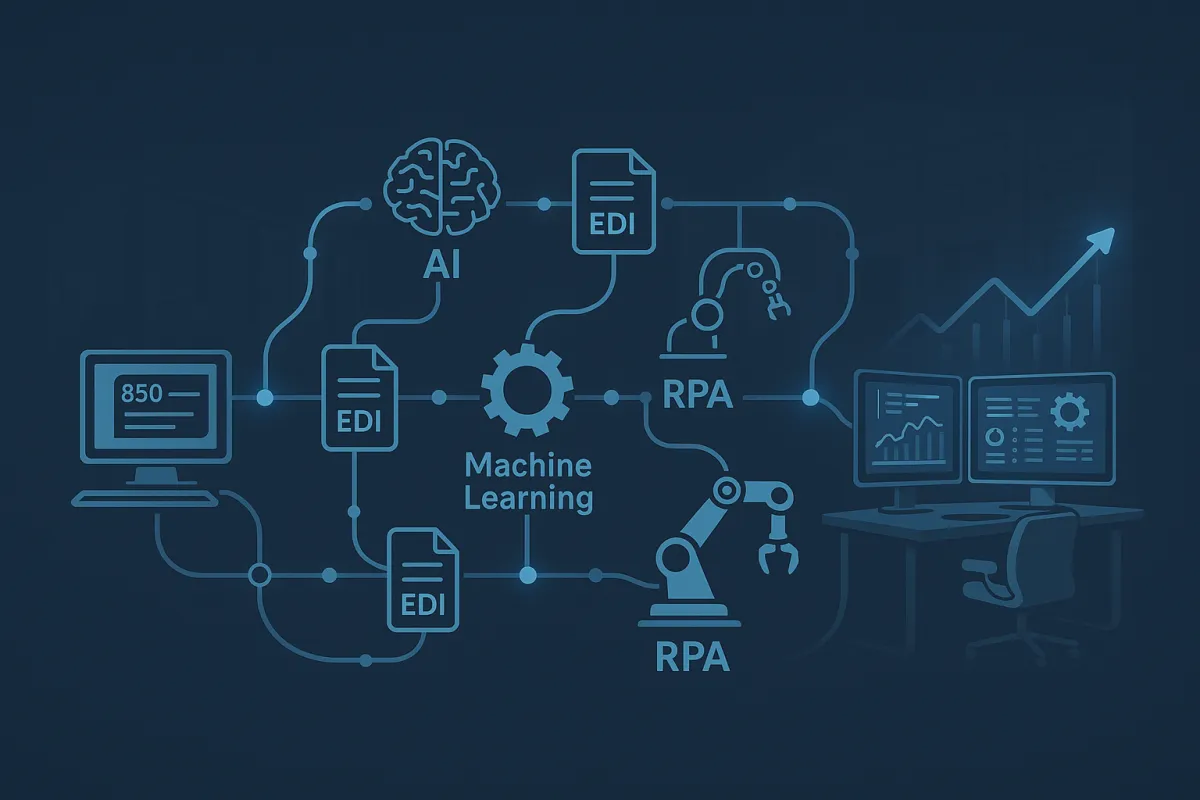

EDI hyperautomation goes far beyond your current rule-based transaction processing. Hyperautomation involves the use of multiple technologies and tools including AI, machine learning, event-driven software architecture and robotic process automation working together to handle complex supply chain scenarios that traditional EDI can't address alone.

Think about your current EDI setup. You receive an 850 Purchase Order, process it through your system, and send back an 855 acknowledgment. That's standard EDI. Now imagine that same transaction triggering AI-powered demand forecasting, automatically adjusting inventory levels based on predictive analytics, and sending RPA bots to update non-EDI partner portals—all without human intervention. That's hyperautomation.

Here's what sets it apart:

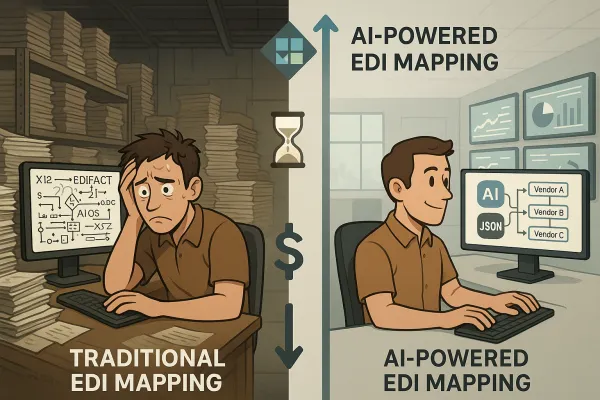

- Intelligent data mapping: AI analyzes incoming transaction patterns and automatically adjusts mapping rules. No more manual updates when trading partners change their data formats.

- Predictive exception handling: Machine learning identifies potential supply chain disruptions before they occur, automatically rerouting orders or adjusting delivery schedules.

- Cross-system orchestration: RPA bots handle the 30% of partners who still use email or web portals, integrating them into your EDI workflow seamlessly.

Companies like Cargoson are building these capabilities alongside established platforms like Cleo's AI integration and MercuryGate's analytics features, creating end-to-end automation that actually learns and adapts.

The Business Case: Why 74% of Companies Fail to Show AI ROI (And How to Avoid Their Mistakes)

The statistics are stark. 74% of companies are struggling to see tangible returns from artificial intelligence despite significant investments and pilot programs over the years. In EDI operations, this failure rate is even more pronounced because many teams approach hyperautomation as a technology problem rather than a business transformation.

The successful 26% share common traits that EDI managers can apply immediately:

They focus on core business functions first. 62% of AI's value lies in core business functions such as operations (23%), sales and marketing (20%), and R&D (13%). For EDI operations, this means automating order processing, shipment tracking, and inventory management before tackling support functions.

They limit their scope initially. Leading companies focus on depth over breadth, prioritizing an average of 3.5 use cases, compared with 6.1 for other companies. Don't try to automate every EDI transaction type simultaneously. Start with your highest-volume transactions or most error-prone processes.

They measure the right metrics. The leaders anticipate generating 2.1 times greater ROI on their AI initiatives than their peers because they track business outcomes, not just technical metrics. Instead of measuring "documents processed per hour," track "perfect order rates" or "exception resolution time."

Consider a automotive parts manufacturer that implemented EDI hyperautomation across their Oracle TM environment. Rather than automating all transaction types, they focused on three scenarios: expedited orders, supplier quality alerts, and logistics exceptions. Within six months, they reduced manual intervention by 78% and improved on-time delivery rates by 12%. The key? They chose processes where automation directly impacted customer experience and operational costs.

Core Components of EDI Hyperautomation Architecture

Building effective EDI hyperautomation requires integrating four key technology layers that work together seamlessly.

Enhanced EDI Processing Layer

Your existing EDI infrastructure becomes the foundation, but enhanced with AI-powered mapping and validation. Machine learning algorithms analyze transaction patterns to identify anomalies and suggest mapping improvements. Instead of manual updates when trading partners modify their formats, the system learns and adapts automatically.

RPA Integration Bridge

Hyperautomation leverages advanced technologies such as AI, machine learning (ML), and robotic process automation (RPA) to enable deeper and more complex use cases for automation. RPA bots handle the integration gaps—updating supplier portals, extracting data from email attachments, and managing exceptions that fall outside standard EDI workflows.

AI Decision Engine

This layer analyzes transaction data in real-time, making intelligent routing decisions and triggering automated responses. For example, when an 856 shipment notice indicates a delivery delay, the AI engine can automatically generate customer notifications, adjust downstream schedules, and initiate alternative sourcing if needed.

Process Orchestration Platform

True end-to-end process orchestration takes a broader view. It aims to streamline whole business processes by coordinating all automation components. This platform manages dependencies, handles exceptions, and ensures each step happens in the correct sequence.

Leading TMS platforms like nShift and E2open are building these capabilities natively, while solutions like Cargoson offer integration-friendly approaches that work with existing EDI infrastructure. The key is choosing components that communicate effectively and share common data models.

Implementation Framework: 7-Phase Approach to EDI Hyperautomation Success

Successful implementations follow a proven methodology that balances technical requirements with business objectives.

Phase 1: Process Mining and Discovery

The algorithms use process mining and machine learning. They sift through massive datasets from ERP systems, CRMs, and other sources. They deliver a transparent, data-backed model of how processes actually work. Start by analyzing your current EDI transactions, exception handling patterns, and manual interventions to identify automation opportunities.

Phase 2: Business Case Development

Quantify the impact of identified opportunities. Calculate current costs for manual processing, error correction, and exception handling. Project savings from automation, but include implementation costs and ongoing maintenance. This phase determines your ROI targets and success metrics.

Phase 3: Technology Architecture Design

Map your existing EDI infrastructure and identify integration points for RPA and AI components. Design data flows between systems and establish governance frameworks. This phase often reveals whether your current EDI platform can support hyperautomation or requires upgrades.

Phase 4: Pilot Program Launch

Select 2-3 high-impact, lower-risk processes for initial automation. Focus on scenarios with clear success criteria and measurable outcomes. Typical pilots include purchase order acknowledgments with automatic inventory checks or shipment notice processing with carrier integration.

Phase 5: Integration and Testing

Connect your pilot automation to existing systems and conduct comprehensive testing. Include trading partner validation to ensure automated processes don't disrupt their operations. This phase often takes longer than expected due to integration complexities.

Phase 6: Scaled Deployment

Expand successful pilots to additional transaction types and trading partners. Implement monitoring and performance management capabilities to track ROI and identify optimization opportunities. This phase requires strong change management as staff adapt to new automated workflows.

Phase 7: Continuous Optimization

Less than 20% of organizations have mastered the measurement of hyperautomation initiatives, so establishing ongoing performance analysis is critical. Regular review of automation effectiveness, ROI measurement, and identification of new automation opportunities.

Solutions like Descartes, Transporeon, and 3Gtms each offer different implementation approaches, with varying levels of technical support and integration assistance. Cargoson provides methodology consulting alongside their platform capabilities, helping teams navigate the technical and organizational challenges.

ROI Measurement Framework: Quantifying Hyperautomation Value in EDI Operations

Measuring hyperautomation ROI requires tracking both traditional EDI metrics and new value indicators that reflect the enhanced capabilities.

Operational Efficiency Metrics

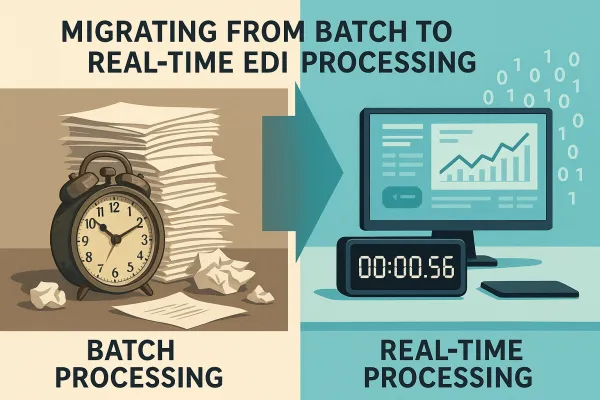

- Transaction processing time: Target 40-60% reduction in average processing time

- Exception resolution rates: Measure percentage of exceptions resolved without human intervention

- Perfect order rates: Track orders processed without errors or delays

- Trading partner onboarding time: Measure reduction in time to activate new EDI relationships

Financial Impact Indicators

- Cost per transaction: Calculate total automation costs divided by transaction volume

- Manual intervention costs: Track reduction in FTE hours required for exception handling

- Error correction costs: Measure savings from reduced data entry errors and rework

- Opportunity cost recovery: Calculate value of staff time redirected to strategic activities

Strategic Value Measures

- Trading partner satisfaction: Survey partners on transaction accuracy and timeliness

- Scalability indicators: Measure ability to handle volume increases without proportional staff increases

- Business agility: Track time to implement new trading partner requirements or process changes

Companies using Manhattan Active and FreightPOP report typical ROI ranging from 200-400% within 18 months, with most value coming from reduced manual processing rather than software cost savings. Cargoson implementations show similar patterns, with fastest returns in high-volume, routine transaction processing.

The key is establishing baseline measurements before implementation and tracking improvements monthly rather than waiting for annual reviews. organizations will lower operational costs by 30% by combining hyperautomation technologies with redesigned operational processes, but only if they measure and optimize continuously.

Real-World Implementation Strategies: Industry-Specific Approaches

Different industries require tailored hyperautomation strategies based on their unique EDI requirements and trading partner ecosystems.

Automotive Manufacturing

Automotive EDI hyperautomation focuses on predictive logistics and quality management. AI analyzes supplier delivery patterns and production schedules to automatically adjust JIT delivery windows. When quality issues arise, the system automatically isolates affected lots, notifies downstream manufacturers, and triggers alternative sourcing. RPA bots update tier-2 and tier-3 supplier portals that don't support EDI, ensuring complete supply chain visibility.

Retail and E-commerce

Retail hyperautomation integrates demand forecasting with EDI transaction processing. Machine learning analyzes sales patterns, seasonal trends, and promotional impacts to automatically generate supplier replenishment orders. When inventory levels trigger reorders, the system considers supplier lead times, transportation costs, and promotional calendars to optimize order timing and quantities.

Manufacturing and Distribution

Manufacturing environments benefit from IoT data fusion with traditional EDI workflows. Sensor data from production equipment automatically triggers maintenance orders through EDI 850 transactions. Quality control systems integrate with shipping notices (856) to include real-time quality certifications. This creates end-to-end traceability without manual data entry.

Industry-specific solutions vary significantly. ShippyPro, Shipmondo, and AfterShip focus primarily on e-commerce fulfillment automation, while Cargoson offers broader manufacturing and enterprise capabilities. The key is choosing solutions that understand your industry's specific EDI requirements and trading partner expectations.

Overcoming Common Implementation Challenges and Risk Mitigation

Every EDI hyperautomation project faces predictable challenges. Successful implementations prepare for these issues and have mitigation strategies ready.

Trading Partner Integration Complexity

Your automation works perfectly until you discover that your largest customer uses non-standard EDI formats. Solution: Implement AI-powered mapping that learns trading partner variations automatically. Include RPA capabilities for partners who require manual portal updates or email-based communication.

Change Management Resistance

when companies undertake digital or AI transformations, they need to focus two-thirds of their effort and resources on people-related capabilities, and the other third or so split between technology and algorithms. Your EDI team may resist automation, fearing job displacement. Solution: Position hyperautomation as capability enhancement, not replacement. Train staff to manage automation systems and handle complex exceptions that require human judgment.

Integration Architecture Challenges

Legacy EDI systems often resist integration with modern AI and RPA platforms. Solution: Implement an integration layer that translates between systems without requiring EDI platform replacement. This approach preserves existing trading partner relationships while enabling new capabilities.

ROI Measurement Difficulties

Less than 20% of organizations have mastered the measurement of hyperautomation initiatives. Many teams struggle to quantify automation benefits. Solution: Establish baseline measurements before implementation and track both hard savings (reduced labor costs) and soft benefits (faster response times, improved accuracy).

Vendor Selection Confusion

The hyperautomation market includes dozens of vendors with overlapping capabilities. Companies like EasyPost, ClickPost, and ShipStation focus on specific logistics functions, while platforms like Cargoson offer broader EDI hyperautomation capabilities. Solution: Map your specific requirements to vendor capabilities rather than choosing based on brand recognition or price alone.

Governance and Compliance Concerns

Automated systems make thousands of decisions daily, raising questions about compliance and audit trails. Solution: Implement comprehensive logging and decision tracking from day one. Ensure your hyperautomation platform provides complete audit capabilities and maintains compliance with industry regulations.

The most successful implementations acknowledge these challenges upfront and allocate sufficient time and resources for change management, staff training, and system integration. Gartner predicts hyperautomation will impact one-fifth of all business processes, driving efficiency and agility in operations, but only for organizations that address implementation challenges systematically.

Ready to start your EDI hyperautomation journey? Begin with process mining to identify your highest-impact automation opportunities. Focus on measurable business outcomes rather than technology features. And remember—successful hyperautomation is 70% people and process, 30% technology. Get the organizational elements right, and the technology will deliver the ROI you need.