The €900K TMS Implementation Reality Check: How to Build the Complete Hidden Cost Prevention Framework That 75% of European Supply Chain Teams Miss Before Signing Contracts

A German automotive parts manufacturer discovered their €800,000 TMS implementation mistake the hard way. Six months into deployment, they found their European carriers couldn't integrate without costly custom development work — turning their "smart procurement decision" into a complete platform re-implementation. Sound familiar?

You're watching 75% of European TMS implementations suffer budget overruns because procurement teams make the same critical mistake. They focus on software subscription fees while missing the implementation expenses that actually determine project success.

This guide shows you how to identify, quantify, and prevent the hidden TMS implementation costs that consistently blindside European supply chain teams. Implementation costs range from €30,000 to €900,000, and for shippers with freight spend exceeding $250M annually, implementation can cost 2-3 times the subscription fee.

The Hidden Cost Categories That Destroy Budgets

Hidden costs in TMS procurement consistently add 25-30% more than initial estimates, but the damage spreads across seven specific categories that procurement teams consistently overlook.

Consider these TCO components: base licensing (20-30% of total), implementation services (25-40%), carrier integration (15-25%), customization and training (10-20%), and ongoing support (15-20%). The percentages reveal why subscription fees alone provide misleading cost projections.

Here's what catches European shippers off-guard: implementation services, carrier connectivity, system customization, training and change management, ongoing support, regulatory compliance, and hidden licensing fees.

Annual maintenance presents another budget trap. Licensed TMS models include annual maintenance charges ranging from 15-20% of license costs, while traditional software maintenance fees often run around 20% of the license fee annually for support and minor upgrades.

The mathematics get worse for complex deployments. For smaller and mid-sized carriers, on-premise costs can quickly escalate beyond $200,000 in the first year, with annual maintenance fees continuing to compound regardless of business performance.

The EDI Integration Cost Trap

Carrier integration costs blindside most procurement teams because vendors present API availability as "included" functionality. While many TMS solutions offer published APIs, carriers are often unwilling or unable to create connections themselves, and even when they can, they typically charge integration costs back to the shipper.

Here's the reality check: many carriers aren't willing or able to create API connections, and even when they are, they'll charge integration costs to you. European shippers working with 20-30 regular carriers face substantial connectivity expenses that vendors rarely discuss during initial demos.

The complexity multiplies with volume requirements. Automation requires setup of connections with internal systems like ERP, plus external carriers for booking, tendering, status messages, and invoicing - and if you work with several carriers, this can be significant.

The initial investment for integration can be substantial, although it is often recouped through long-term savings. But without proper cost modeling, those "long-term savings" become speculative promises rather than guaranteed returns.

EDI integration challenges compound during TMS migrations. Because TMS and EDI systems are deeply connected, even minor mismatches between the two systems can lead to costly disruptions. EDI and TMS systems are tightly intertwined. Everything from tendering loads to confirming delivery relies on structured, automated data flows.

The Complete TCO Framework

Building an accurate five-year cost model requires breaking down expenses into predictable categories and realistic timelines.

Phase 1: Assessment and Planning (Months 1-2)

Budget €15,000-€50,000 for comprehensive requirements analysis. To ensure optimal outcomes, shippers should begin by clearly defining the value they expect a TMS to deliver. This enables businesses to select the right solution, streamline implementation, and position the system for sustained success.

Include costs for: business process documentation, integration architecture design, vendor evaluation workshops, and change management planning.

Phase 2: System Configuration (Months 3-6)

Several factors influence TMS implementation costs. Careful evaluation of these elements can help shippers minimise expenditure while maximising the system's potential.

Configuration expenses typically include: workflow automation setup, business rule development, user interface customization, and testing environment preparation.

Phase 3: Integration Development (Months 4-8)

Trading Partner Onboarding: $750-$2,500 per partner for setup, mapping, and testing. With multiple partners, these one-time fees become substantial recurring costs as you grow.

Factor in ERP connectivity, carrier API development, EDI mapping and testing, and custom integration development where pre-built connectors don't exist.

Phase 4: Training and Deployment (Months 6-9)

Training costs often get underestimated. Plan for: end-user training programs, administrator certification, process documentation, and go-live support.

Ongoing Operational Costs (Years 2-5)

VAN Connectivity Fees: $500-$2,000 monthly for VAN mailbox setup, ongoing connectivity, and data transmission infrastructure. Add system monitoring, performance optimization, regulatory compliance updates, and vendor support contracts.

The Procurement Protection Strategy

Contract negotiation becomes your first defense against budget overruns. Focus on these specific areas:

Fixed-Price Implementation Guarantees: Negotiate caps on implementation services. Integration Customization: $150+ per hour to build and maintain point-to-point integrations for each trading partner relationship. Overage Fees: Penalties when you exceed volume tiers, often charged retroactively on all transactions for the month.

Carrier Integration Transparency: Demand clear documentation of included carrier connections versus additional charges. Some TMS providers offer published APIs for carrier integration. However, carriers may charge shippers for establishing these connections. Opting for a TMS with an extensive pre-connected network can significantly reduce connectivity costs and ensure smoother operations.

Change Order Controls: Establish approval processes for scope changes and require written estimates before additional work begins.

Performance Guarantees: Include specific timeline commitments with financial penalties for delays.

European Market Considerations

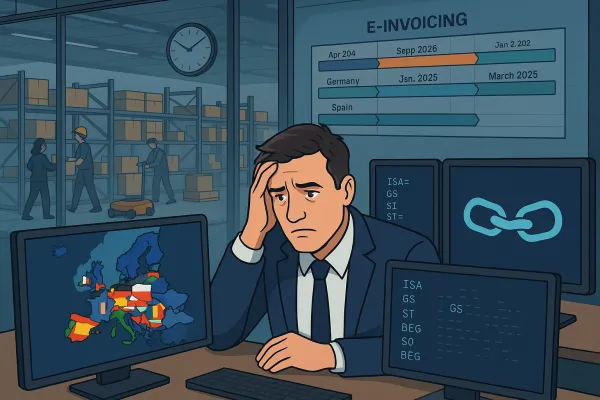

European shippers face unique implementation challenges that North American-focused vendors often underestimate.

Your 12-country carrier networks, multi-modal requirements, and regulatory compliance demands create cost pressures that basic TMS comparisons miss. Multi-country implementations require additional configuration for: currency handling, tax calculations, customs documentation, and local carrier requirements.

Regulatory compliance adds another cost layer. Europe leads in sustainability-driven TMS adoption due to strict emissions regulations, carbon reporting mandates, and low-emission zone compliance. Companies are now focusing their resources on implementing TMS systems with tools for measuring CO2 emissions, decarbonizing routes, finding optimized alternative methods of transport, and developing consolidated loads.

The eFTI deadline approaches faster than you think. The July 2027 deadline approaches faster than you think, and the benefits of early implementation extend far beyond regulatory compliance. Factor compliance preparation costs into your implementation timeline.

Implementation Success Framework

Budget control starts with realistic timelines and proven methodologies.

Phase-Gate Approach: Break implementations into measurable milestones with go/no-go decision points. This prevents scope creep and allows course corrections before costs spiral.

Pilot Program Strategy: The 24% who succeed follow proven methodologies, plan for hidden costs, and choose platforms built for European compliance requirements. The 76% who struggle skip the planning, underestimate the complexity, and treat their TMS like a simple software purchase rather than a strategic transformation.

Start with a limited carrier network and geographical scope. Prove the system works before expanding to full deployment.

Vendor Selection Criteria: When evaluating solutions, consider established providers like Cargoson alongside Oracle TM, SAP TM, MercuryGate, and Descartes. Each offers different approaches to European carrier connectivity and implementation complexity.

Success Metrics: Define measurable objectives beyond cost savings. Track: carrier onboarding timeframes, transaction accuracy rates, user adoption percentages, and system uptime performance.

Risk Mitigation: Plan for: vendor acquisition risks, regulatory changes, carrier API modifications, and technology obsolescence.

Most importantly, by evaluating implementation costs through the lens of long-term value, shippers can make informed decisions that optimise their TMS investment. A focus on upfront planning, stakeholder alignment, and strategic cost control will not only limit one-time expenses but also establish a foundation for enduring operational efficiency and ROI.

The European TMS market continues evolving rapidly. Europe transportation management system market accounted for a share of 26.5% and generated revenue of USD 4 billion in 2025. Use this framework to avoid becoming another budget overrun statistic.