The Hidden $500K Hybrid Order Processing Crisis: How AI-Powered PDF Automation Eliminates the EDI Gap and Unifies Mixed Trading Partner Networks in 2026

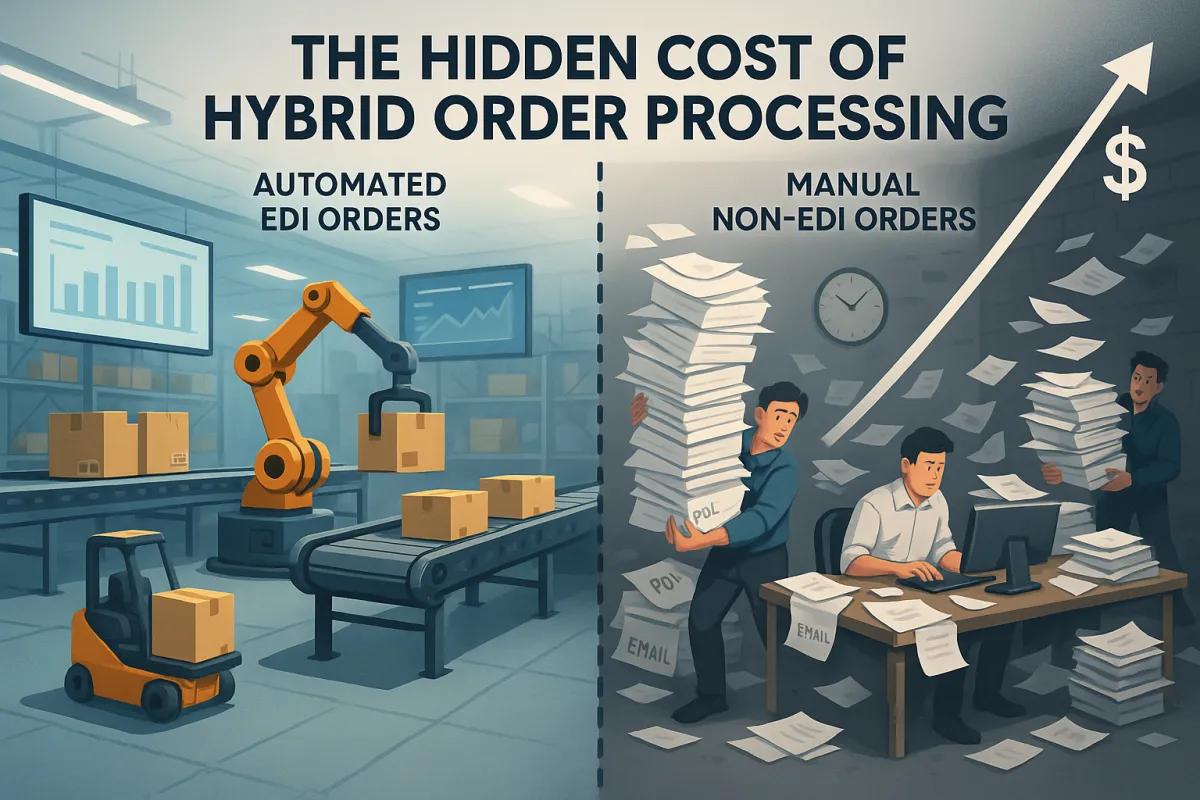

Your supply chain operations already depend on hybrid EDI automation to handle trading partners at different technological stages. The harsh reality? You work with a mix of retailers and clients who still send orders by PDFs, spreadsheets, emails and attachments. This creates a costly operational tax that compounds every time you manually process non-EDI orders alongside your automated workflows.

The hidden costs run deeper than most supply chain leaders realize. A major electronics manufacturer calculates the cost of processing an order manually at $38 compared to just $1.35 for an order processed using EDI. That $36.65 difference per order adds up fast when you're processing thousands of PDF orders monthly from customers who haven't adopted EDI standards.

The Costly Reality of Hybrid Trading Partner Networks

Modern supply chain operations exist in a mixed technology environment by necessity. Manually entering orders into your system costs you both time and resources, driving up cost per order and slowing down the floor, especially during peak volume. The more your business grows, the more manually processed PDFs and emails simply cannot keep pace with client onboarding or seasonal volume spikes.

3PLs face this challenge daily. You might handle EDI transactions from Walmart through your established networks, then receive PDF purchase orders from the same retailer's marketplace vendors who lack EDI capabilities. This forces warehouse teams to switch between automated and manual processing modes, creating operational friction that impacts overall efficiency.

The problem extends beyond simple data entry. The fallout of mis-keyed data for your business can be picking mistakes, incorrect shipments, chargebacks, damaged client trust and missed SLAs. When your EDI orders process flawlessly but PDF orders introduce errors, you're essentially running two different quality standards within the same operation.

Quantifying the Hidden Operational Tax

The financial impact of manual PDF processing creates measurable drain on your operations. Processing times down by 50 to 70%. Cost per document halved when businesses implement proper automation.

Consider these cost factors accumulating in your current mixed environment:

- Labor costs for manual order entry at $15-25 per hour

- Error correction cycles averaging 20-30 minutes per mistake

- Processing delays that impact warehouse scheduling

- Customer service time spent on order discrepancies

- System switching overhead between manual and automated workflows

A 3PL processing 500 PDF orders monthly alongside their EDI volume faces roughly $19,000 in additional operational costs compared to full automation. Scale that across enterprise operations, and you're looking at hundreds of thousands in hidden expenses.

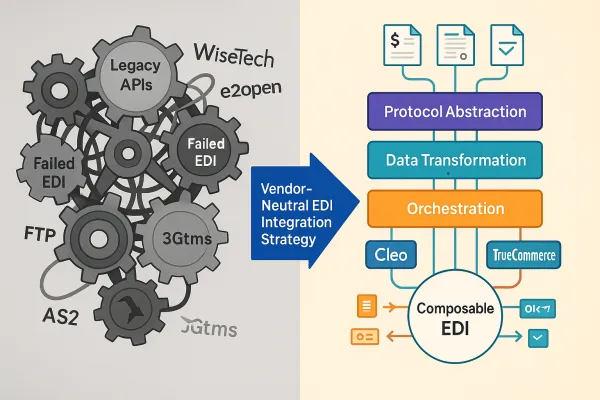

Why Traditional OCR Solutions Fail in Enterprise Environments

OCR behaves like a scanner: it recognizes characters, not meaning. For 3PLs, where order accuracy determines pick efficiency and shipment correctness, that's a problem. Legacy OCR technology reads text but doesn't understand document structure, field relationships, or the business context necessary for reliable order processing.

Traditional OCR struggles with real-world challenges that are commonplace in supply chain operations:

- Variable document layouts from different customers

- Poor scan quality from faxed or photocopied orders

- Mixed languages and character sets in global operations

- Complex table structures with multiple line items

- Handwritten annotations and modifications

These limitations force businesses to build manual review processes that negate the efficiency gains automation should provide.

The TMS Integration Challenge

Your transportation management system expects structured, validated order data to execute shipments efficiently. Manual PDF processing creates integration gaps that impact your entire logistics workflow. When order data requires manual validation before entering your TMS, you're introducing delays that cascade through carrier selection, route optimization, and customer communication.

Modern TMS platforms like Cargoson, nShift, and FreightPOP excel at automated execution when fed clean, structured data. The challenge lies in getting PDF order data into the same reliable format as your EDI transactions. Without this consistency, your TMS operates with incomplete automation benefits.

AI-Powered PDF Order Automation: Beyond Character Recognition

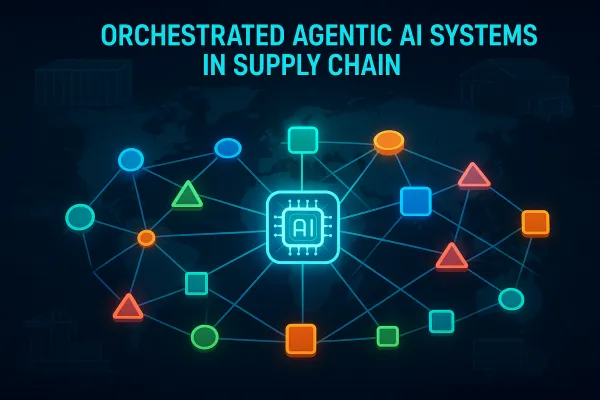

Modern PDF order automation leverages artificial intelligence to understand document structure and meaning rather than simply reading characters. AI-assisted mapping and translation seamlessly integrates your orders into Fulfillment. This represents a fundamental shift from traditional OCR approaches.

The technology works by:

- Learning document layouts and field relationships automatically

- Understanding business context and validation rules

- Adapting to new document formats without manual programming

- Maintaining accuracy rates above 95% for complex documents

PDF Order Automation uses your existing Fulfillment integrations to map and translate non-EDI orders directly into your EDI workflow. This means you can process PDF orders through the same automated systems that handle your EDI transactions, eliminating the operational complexity of managing dual workflows.

Real-World Implementation Examples

Companies implementing AI-powered PDF automation report significant operational improvements. DeAgostini processed 54,000 supplier invoices in a year without disrupting operations using SAP Document AI to automate processes. In supply chain applications, similar automation enables global operations to handle multiple document formats and languages seamlessly.

Extract text and information from documents in more than 100 languages to effortlessly scale your global operations. For multinational 3PLs and manufacturers, this capability eliminates the complexity of managing region-specific manual processes while maintaining consistent automation standards across all markets.

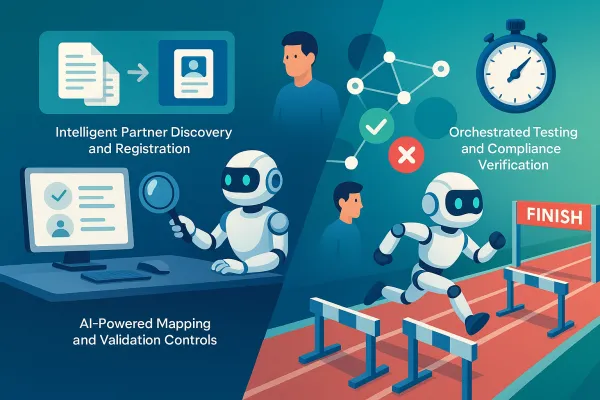

Building Your Hybrid Automation Strategy

Implementing PDF order automation alongside existing EDI workflows requires a structured approach that minimizes disruption while maximizing efficiency gains. Start by assessing your current mixed trading partner landscape to identify the highest-impact automation opportunities.

Your implementation framework should address these key areas:

- Document volume analysis by trading partner and format

- Integration requirements with existing EDI and TMS systems

- Accuracy thresholds needed for warehouse execution

- Exception handling workflows for complex orders

- Training requirements for operational teams

When evaluating solutions, consider both specialized PDF automation platforms and TMS-integrated approaches. Solutions like SPS Commerce PDF Order Automation focus specifically on the EDI integration challenge, while transportation management platforms including Cargoson and others may offer document automation as part of broader logistics automation suites.

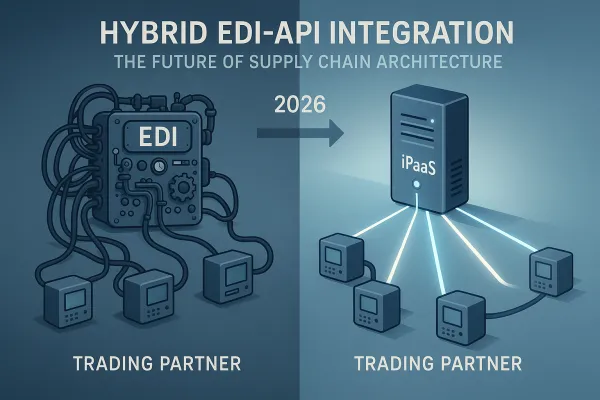

Integration Architecture Considerations

When you manage your EDI processes with SPS Commerce Fulfillment, you already have access to 400+ pre-built system integrations for ERP, OMS, WMS solutions and more. Our PDF Order Automation uses your existing Fulfillment integrations. This architectural approach enables you to leverage current EDI infrastructure investments rather than building parallel systems.

Your integration architecture should ensure PDF orders flow through the same validation, routing, and exception handling processes as EDI transactions. This consistency prevents the quality gaps that typically emerge when manual processes operate alongside automated workflows.

ROI Calculation Framework and Success Metrics

Measuring the business impact of eliminating manual PDF processing requires tracking both direct cost savings and operational efficiency improvements. Automation gets judged on quantifiable results. Processing times down by 50 to 70%. Exception rates under 5%. Cost per document halved. Success is measured against operational KPIs, not transformation slogans.

Your ROI framework should track these key metrics:

- Labor cost reduction from eliminated manual entry

- Error rate improvements and associated cost savings

- Processing time reductions across order-to-fulfillment cycles

- Warehouse efficiency gains from consistent order quality

- Customer satisfaction improvements from faster, more accurate processing

The right platform can reduce processing time by 70-80% while improving data quality. Organizations typically see processing time reductions of 70-80% when implementing AI document automation. These efficiency gains compound when applied across high-volume operations, creating substantial competitive advantages for companies that successfully eliminate the operational tax of mixed EDI and non-EDI processing.

The businesses winning in 2026 supply chain operations won't be those with the most advanced EDI networks alone, but those that successfully automate the entire spectrum of trading partner interactions. Automating non-EDI orders isn't just about saving time—it's a strategic move that prepares you to move ahead in a competitive market and accelerate your growth.