The Hybrid EDI-API Integration Playbook: How to Modernize B2B Data Exchange Without Breaking Your Supply Chain in 2025

Your CFO just asked why you're spending another $200K on EDI infrastructure when "APIs are the future." Meanwhile, your biggest supplier still sends ASNs via X12, and your warehouse management system was built when Clinton was president. You're caught between the promise of modern integration and the reality of legacy systems that actually work.

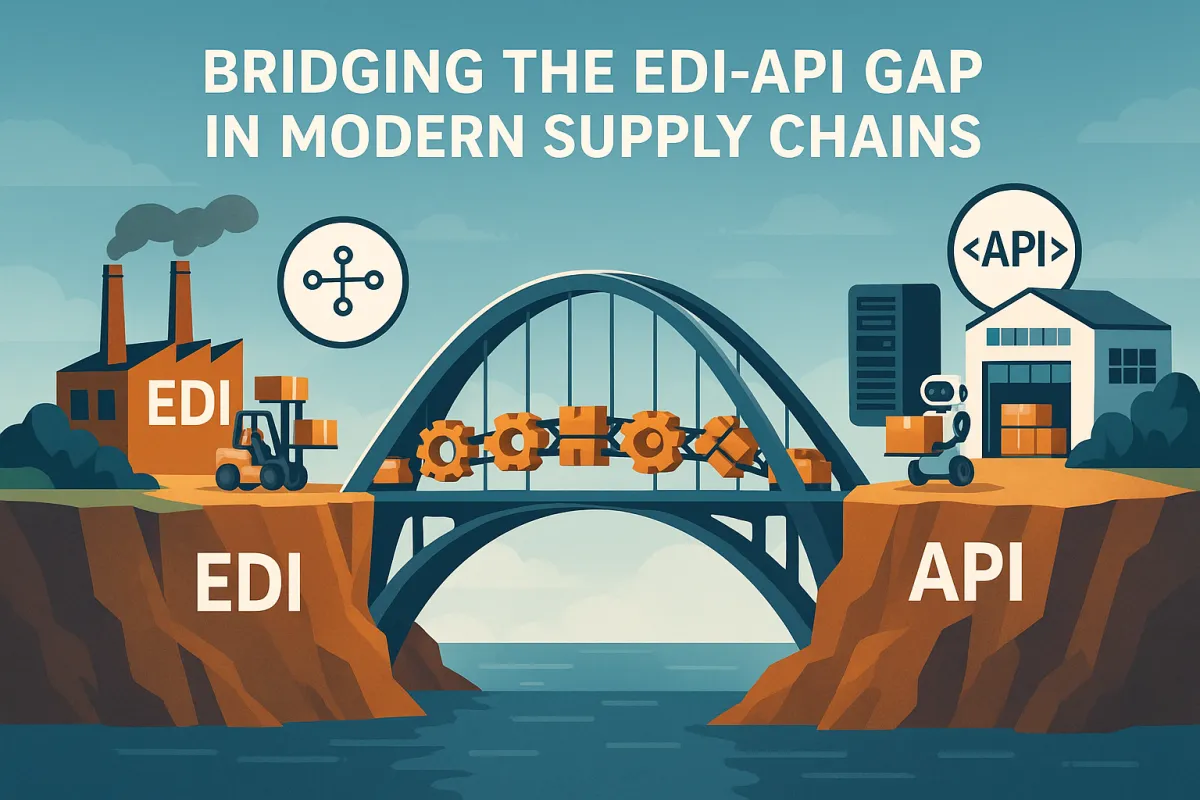

The truth is, hybrid EDI integration isn't a compromise—it's the only practical path forward for organizations managing complex supplier networks. Rather than viewing this as EDI versus API, successful companies are building systems where both technologies complement each other.

The Reality Check: Why Pure Migration Strategies Fail

Most "API migration" projects stall because they assume you can flip a switch. You can't. The global EDI market is projected to grow from $2.31 billion in 2025 to $5.30 billion by 2032, which tells you everything about EDI's staying power.

Here's what kills pure migration strategies:

- Your top 10 suppliers represent 60% of your volume, and they're not changing their EDI setup for you

- That custom EDI mapping you built in 2019? It handles 47 different supplier variations that would take months to recreate

- Your ERP system processes 15,000 EDI transactions daily without issues—why break what works?

Major transportation management systems like MercuryGate and Descartes have figured this out. They don't force you to choose between EDI and APIs. They support both because real supply chains need both.

Understanding the Hybrid Integration Architecture

Think of hybrid EDI-API integration like having multiple languages for different conversations. EDI handles the structured, standardized transactions that your suppliers already know. APIs provide real-time connectivity for dynamic data that changes by the minute.

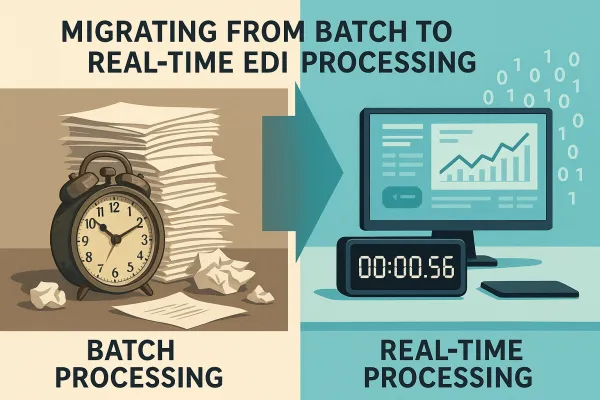

Here's how the architecture actually works: Your existing EDI connections continue processing purchase orders, invoices, and ASNs through established protocols. Meanwhile, API-driven integration enables real-time data exchange for inventory levels, shipment tracking, and exception handling.

The key insight? Your cloud-based EDI service provider becomes the integration hub. Instead of managing dozens of point-to-point connections, you get a single API that connects to your internal systems while maintaining all your existing EDI relationships.

Consider inventory validation: Your EDI system receives a planned shipment notice, but your API connection immediately checks current warehouse capacity and routing constraints. If there's a problem, the API triggers an exception workflow while the EDI system continues normal processing.

The Strategic Implementation Framework

Assessment and Planning

Start with a partner analysis, not a technology audit. Group your trading partners into three categories:

EDI Stalwarts: Large suppliers who process thousands of transactions monthly via established EDI connections. These relationships stay as-is because the cost of change exceeds any potential benefit.

API Ready: Smaller, tech-forward partners who prefer REST APIs and real-time data exchange. These become your pilot group for hybrid integration.

Mixed Requirements: Mid-size partners who use EDI for core transactions but need API connectivity for tracking, exceptions, and analytics.

Your migration strategy depends on your current landscape. Brownfield approaches maintain existing EDI infrastructure while adding API layers. Greenfield implementations start fresh but require massive partner coordination. Bluefield combines both by creating parallel systems.

Phased Rollout Strategy

Never migrate your highest-volume partners first. Start with specific use cases where APIs provide clear advantages over EDI.

Phase 1 focuses on exception handling and real-time visibility. Your purchase orders still flow via EDI, but delivery exceptions trigger immediate API notifications to your transportation management platform.

Phase 2 adds inventory synchronization for partners who can support it. EDI handles the formal inventory adjustments, while APIs provide real-time balance updates.

Phase 3 introduces hybrid order processing where urgent orders use API connections for speed, while standard orders continue via EDI for audit trails and compliance.

Each phase requires backup EDI feeds. When your API connection to a key supplier fails at 2 AM, you need the EDI fallback ready to activate automatically.

Technology Stack and Platform Selection

Your platform choice determines success or failure. Look for solutions that treat EDI and API integration as complementary, not competing approaches.

Enterprise integration platforms like nShift and Transporeon handle carrier connectivity through both EDI and API protocols. Cargoson provides similar multi-carrier shipping capabilities with native support for both integration methods. These platforms don't make you choose between technologies.

The technical requirements are specific: You need real-time data transformation between EDI formats and API payloads. When an X12 850 purchase order arrives via EDI, your platform should expose that data through REST APIs to downstream systems. Conversely, when your inventory system sends an API update, it should trigger appropriate EDIFACT messages to trading partners who expect them.

Cloud-native EDI platforms excel here because they provide API-driven integration capabilities without abandoning proven EDI protocols. You get modern interfaces for your internal systems while maintaining established B2B relationships.

Security and Compliance Considerations

Hybrid integration multiplies your security surface area. Now you're securing both EDI connections and API endpoints, often with different protocols and authentication methods.

Your EDI connections likely use AS2 or SFTP with established security protocols. Your APIs require OAuth 2.0, proper rate limiting, and API key management. Managing both simultaneously requires careful planning.

Compliance gets complicated too. EDI maintains structured, standardized transactions that auditors understand. API data flows can be more dynamic and harder to audit. You need logging and monitoring that captures both integration methods comprehensively.

GDPR affects both sides. Your EDI transactions might contain personal data that requires specific handling, while your APIs enable real-time data sharing that could violate data minimization principles if not properly configured.

Real-World Success Patterns and ROI Metrics

The numbers tell the story. Organizations using hybrid approaches report 40% faster exception resolution because APIs handle urgent communications while EDI processes routine transactions.

OneHealthPort processes over 50 million EDI transactions annually, but they've added API layers for real-time eligibility checking and claims status updates. The hybrid approach reduced processing errors by 23% because real-time API validation catches problems before they become EDI exceptions.

Cost analysis reveals interesting patterns. Pure EDI implementations cost about $15 per trading partner monthly for basic connectivity. Adding API capabilities increases this to roughly $25 per partner, but the error reduction and faster processing typically save $200-400 per incident avoided.

The ROI calculation depends on your exception volume. If you handle fewer than 100 exceptions monthly, the cost increase may not justify hybrid integration. Above 500 exceptions monthly, the business case becomes compelling.

Future-Proofing Your Integration Strategy

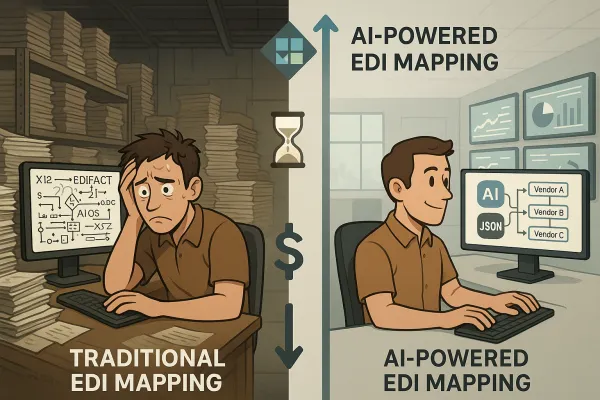

Here's what's coming: AI integration for trend analysis and automated supply chain optimization. Your hybrid platform needs to support machine learning models that can analyze both EDI transaction patterns and real-time API data flows.

Gartner predicts that 50% of supply chain transactions will be real-time by 2025. This doesn't mean abandoning EDI—it means creating systems where EDI provides the structured foundation while APIs enable real-time enhancements.

Blockchain integration is emerging for transaction verification between EDI and API systems. When an EDI transaction occurs, blockchain technology can create immutable records that APIs can reference for real-time verification.

IoT integration represents the biggest opportunity. Your EDI systems handle planned shipments, but IoT sensors provide real-time location and condition data via APIs. Transportation execution software from providers like Cargoson and established players increasingly supports both data streams in unified dashboards.

The successful integration strategy for 2025 isn't about choosing between EDI and APIs. It's about building systems where both technologies enhance each other's strengths while covering each other's weaknesses. Your suppliers get to keep their proven EDI workflows while your internal systems gain the real-time capabilities that modern supply chains require.

Start small, measure carefully, and remember that the best integration is the one that actually works when your biggest customer calls with an urgent order change.