7 Critical EDI Integration Challenges (And How to Solve Them in 2025)

Introduction

Your EDI system just broke three trading partner connections after upgrading your TMS last weekend. The finance team is breathing down your neck about failed ASN transmissions. And that new supplier you've been trying to onboard for two months? Still not live.

EDI continues its explosive growth trajectory, with B2B electronic sales rising from $7 trillion in 2019 to $8.38 trillion by 2021, accounting for 76.5% of all digital commerce and growing year-over-year by 8.3%. Yet despite this momentum, companies expanding their capabilities or traversing high-growth periods face significant EDI integration challenges.

These challenges aren't just minor inconveniences. Research by Ovum shows that 53% of enterprises experience limitations with their current B2B integration solutions when onboarding trading partners, with approximately 40% requiring over 30 days to bring a new partner online. That delay translates directly into lost revenue and strained relationships.

Supply chain professionals working with 100+ trading partners know these problems intimately. The good news? Most EDI integration challenges follow predictable patterns, which means they have proven solutions.

1. Data Mapping and Format Inconsistencies

Here's the dirty secret about EDI standards: they're not actually standardized.

Despite EDI being a standard protocol, trading partners often have their very own flavor of EDI transaction sets. A standard EDI purchase order varies from one trading partner and industry to another. When companies add more customers to their ecosystem, accommodating unique requirements and business rules becomes a hassle.

You'll encounter different interpretations of EDIFACT standards across European suppliers, ASC X12 variations from North American partners, and specialized formats like TRADACOMS in the UK retail sector. One automotive manufacturer we worked with discovered they needed 47 different mapping variations for what should have been a standard 850 purchase order across their supplier base.

Older formats of EDI such as EDIFACT and IMP were unable to handle bad data proactively, leading to erroneous B2B transactions. However, modernized EDI solutions can combat this challenge easily.

Solutions that actually work:

Deploy an EDI platform with any-to-any integration capabilities. Look for solutions that offer pre-built mapping templates but allow extensive customization. Companies like Cargoson, Cleo, and TrueCommerce excel at handling multiple format variations from a single interface.

Modern data mapping solutions leverage artificial intelligence (AI) to map data fields from a source format to a target format, dramatically reducing the time spent on manual mapping corrections.

Establish a data governance council that maintains mapping documentation and validates all new partner requirements against existing standards before implementation begins.

2. TMS and ERP System Integration Problems

Your TMS migration just turned into an EDI nightmare. Sound familiar?

When transportation management systems are upgraded or replaced, EDI connections often break without warning. EDI and TMS systems are tightly intertwined—everything from tendering a load to confirming delivery relies on structured, automated data flows. When systems are swapped out without an EDI continuity plan, the result is often delays, chargebacks, or failed deliveries.

The root problem goes deeper than migration issues. ERP, TMS, and WMS tend to have very lightweight EDI processing. Companies may need different communication software to support various protocols, scripts to complete EDI processing, scripts for database table lookups, or integration between different databases.

Data in an organization flows into different applications from various ecosystem players. An order may go to the core ERP, stock transfers to the WMS, and shipping information to the TMS. If EDI is bundled inside core ERP, businesses may not seamlessly process EDI for WMS or TMS transactions like 940s, 204s, or 214s because ERPs may lack applicable fields or modules.

Here's a real example: USA Truck discovered their EDI tools couldn't scale when they expanded their carrier network from 200 to 500+ partners. Processing times increased from 2 minutes to 45 minutes for standard load tenders.

The fix requires architectural thinking:

Implement a best-of-breed EDI solution that sits independently from your TMS and ERP systems. Platforms like MercuryGate, Descartes, and Cargoson offer robust middleware that can communicate with multiple core systems simultaneously.

Look for prebuilt TMS document flows and templates for common documents like 204s and 210s to shorten implementation time and improve reliability. Consider how your TMS and EDI tools will work with other core systems—a solution that can simplify ERP/EDI integration will reduce duplication and help you adapt faster as your tech stack evolves.

Standalone EDI systems are critical business applications that most organizations treat as tier 1 applications, since more than half of their business revenue goes through this platform. Companies want 100% uptime, even when performing upgrades to their ERP or TMS systems.

3. Trading Partner Onboarding Complexity

You just signed a major new customer. They want EDI connectivity in 30 days. Your current process takes 90 days minimum.

Nearly two-thirds (63%) of IT decision-makers say the EDI onboarding process takes too long because of all the different customized requirements demanded by trading partners. Up to 47% of IT managers say that slow EDI supplier onboarding is currently keeping their businesses from capturing new revenue opportunities.

The complexity multiplies when dealing with suppliers who have limited EDI experience. Don't underestimate the challenge of onboarding a supplier with little experience using EDI. These partners often require extensive hand-holding, multiple test cycles, and additional validation steps.

Large retailers like Walmart now demand new trading partners adopt and implement EDI as the base price of entry to do business, creating pressure for faster onboarding without sacrificing quality.

Proven acceleration strategies:

Deploy self-service onboarding portals that allow partners to configure basic connection parameters themselves. Centralized solutions come pre-loaded with B2B connectors that provide a repository of hundreds of pre-configured, ready-to-deploy communication templates to major trading partners in the supply chain.

Create carrier integration software partnerships. Solutions like nShift, Transporeon, and Cargoson offer pre-built connectors to major shipping carriers, reducing onboarding time from weeks to hours for common logistics partners.

Establish a tiered onboarding process: Tier 1 for simple, standard connections (target: 5 days), Tier 2 for moderate customization (15 days), and Tier 3 for complex, multi-system integrations (45 days maximum).

4. Data Quality and Validation Issues

Bad data kills more EDI projects than integration complexity ever will.

Bad data can significantly hinder supply chain operations, leading to delays and errors. To ensure data integrity, businesses can implement data validation and cleansing at entry points. Machine learning can identify and correct recurring issues, improving overall data quality. By addressing bad data through EDI integration, businesses can optimize supply chain processes and minimize disruptions.

The validation challenge becomes acute when dealing with transportation data. Freight charges, delivery dates, and shipment weights need validation against contractual terms and carrier capabilities. A single misplaced decimal point in weight data can trigger costly routing errors.

EDIFACT formats were not meant for humans to read or understand, which means catching and fixing errors is challenging and requires specific (and increasingly uncommon) skill sets.

AI-powered solutions show real promise:

Implement automated validation rules that check data against predefined business rules before transmission. Configure alerts for anomalies like shipment weights exceeding vehicle capacities or delivery dates that violate service level agreements.

Deploy machine learning algorithms that learn from historical correction patterns. After processing thousands of transactions, these systems can predict and auto-correct common data entry errors with 90%+ accuracy.

Use freight management software that validates charges against contracted rates in real-time. This catches billing discrepancies before they become disputes.

5. Scalability and Performance Bottlenecks

Your EDI system handled 1,000 transactions per day beautifully. At 10,000 transactions, it's choking.

Top EDI challenges include the inability to scale, bad data, and a lack of speed and visibility. Traditional on-premise EDI systems hit performance walls when transaction volumes spike during peak seasons or business growth.

The scalability challenge extends beyond raw processing power. As you add trading partners, each brings unique communication protocols, data formats, and timing requirements. A system that works with 50 partners may become unmanageable at 200 partners without proper architecture.

Cloud-native architectures solve most scaling issues:

Cloud-based EDI solutions offer flexible, on-demand resources that can easily accommodate growth. By investing in automated onboarding processes and self-service portals for trading partners, businesses can handle expansions with reduced manual intervention. These advancements enable efficient scaling of programs.

Consider multi-carrier shipping software like ShipStation, Sendcloud, or Cargoson that can distribute load processing across multiple carriers and service providers automatically. This prevents single points of failure during peak periods.

Implement horizontal scaling capabilities that automatically provision additional processing resources during high-volume periods. Many transportation management platforms now offer auto-scaling features that adjust capacity based on transaction load.

6. Security and Compliance Requirements

Your customer just asked for GDPR compliance documentation for your EDI flows. Your legal team wants to know about data retention policies. The IT security team flagged your AS2 certificates as expiring next month.

Compliance requirements vary dramatically across industries and regions. EDI adheres to standardized document formats and communication protocols, helping businesses comply with industry regulations such as HIPAA, GDPR, and other global standards. By ensuring compliance, businesses reduce the risk of legal penalties.

The security landscape is evolving rapidly in 2025. End-to-end encryption is becoming table stakes, not a premium feature. Access controls need to be granular enough to support role-based permissions while maintaining audit trails for compliance reporting.

Build security into your EDI architecture:

Implement zero-trust security models that verify every transaction and connection, regardless of source. Use certificate-based authentication for all trading partner connections, with automated renewal processes to prevent expiration-related outages.

Deploy data masking and tokenization for sensitive information like pricing data or customer details. This allows you to maintain operational visibility while protecting confidential business information.

Establish automated compliance reporting that generates audit trails for regulatory reviews. Many modern EDI platforms can produce GDPR deletion reports or HIPAA access logs automatically.

7. Cost Control and Resource Management

Your CFO just asked for a breakdown of EDI costs per trading partner. You realize you're paying for three different EDI providers, plus internal staff time, plus consultant fees for that migration project that's still running.

The true cost of EDI extends far beyond software licensing. Setting up EDI requires considerable initial investment in infrastructure, software, and skilled personnel. Factor in ongoing maintenance, partner management, and periodic system upgrades.

Many organizations underestimate the hidden costs of managing multiple EDI vendors. Suppliers often use different EDI vendors for every new trading partner connection without realizing they can consolidate all EDI services with a single provider. This fragmentation causes suppliers to lose approximately $27K in yearly revenue per trading partner and pay 35% more in EDI costs.

Strategic cost optimization approaches:

Consolidate EDI services with a single managed service provider that can handle multiple trading partners and protocols. This reduces administrative overhead and often delivers better pricing through volume commitments.

Use transportation spend management platforms that provide visibility into EDI-related costs alongside freight expenses. This helps identify optimization opportunities like consolidating shipments or negotiating better rates with high-volume partners.

Consider hybrid deployment models that combine cloud-based processing with on-premise data storage for sensitive information. This balances cost efficiency with security requirements.

Best Practices for Preventing EDI Integration Problems

The most successful EDI implementations follow these principles:

Start with comprehensive planning: Before implementing EDI, evaluate your current supply chain processes to identify inefficiencies and where EDI can bring the most value. Map out all document exchanges within your supply chain, from purchase orders to invoices and shipping notices. Identify which documents are exchanged most frequently, then identify challenges.

Build supportive organizational frameworks: Train your team on both technical and business aspects of EDI. Create cross-functional teams that include IT, operations, and business stakeholders. EDI success depends on organizational buy-in, not just technical implementation.

Use APIs for real-time capabilities: EDI and API are complementary technologies that work best together. API integration augments EDI and gives deeper context to B2B integrations with your digital ecosystem, while EDI helps enable downstream business processes and data orchestration. APIs may be necessary to look up catalog inventory or check pricing, while EDI may be necessary to kick-start the ordering, shipping, and fulfillment processes.

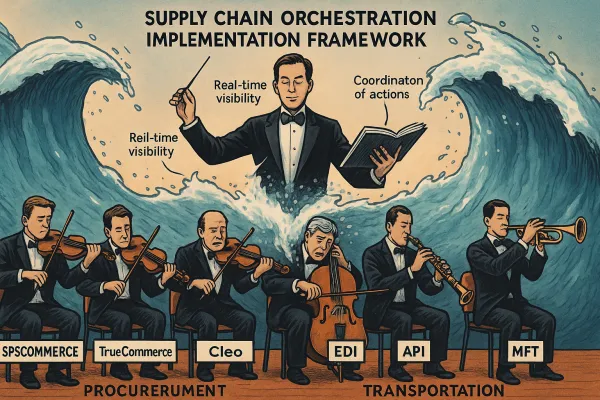

Modern transport execution software addresses many of these challenges by providing unified platforms that handle EDI, API, and hybrid communication methods from a single interface.

Looking Ahead: The Future of EDI Integration

Despite predictions of EDI's demise, EDI is not only here to stay but is set to expand, with the global EDI market projected to value $49.213 billion by 2027.

The companies that thrive will be those that solve these integration challenges systematically rather than treating them as isolated technical problems. Your competitive advantage comes from executing these solutions faster and more reliably than your competitors.

If you're dealing with multiple EDI integration challenges simultaneously, start with data quality and partner onboarding. These improvements deliver immediate ROI while building the foundation for addressing larger architectural issues.

The next time your TMS upgrade threatens to break EDI connections or a major customer demands faster onboarding, you'll have the framework to respond confidently. These challenges are solvable—the question is whether you'll solve them proactively or reactively.