The B2B Ecommerce-EDI Integration Crisis: How to Eliminate Data Mapping Failures and Build Unified Transaction Workflows That Don't Break Your TMS Operations in 2026

Manufacturing and distribution companies discover a harsh reality when upgrading their digital operations: ecommerce and EDI are no longer separate systems inside manufacturing and distribution companies. Together, they form the digital backbone that determines how efficiently orders move, how accurately information flows and how effectively companies compete in an increasingly automated supply chain.

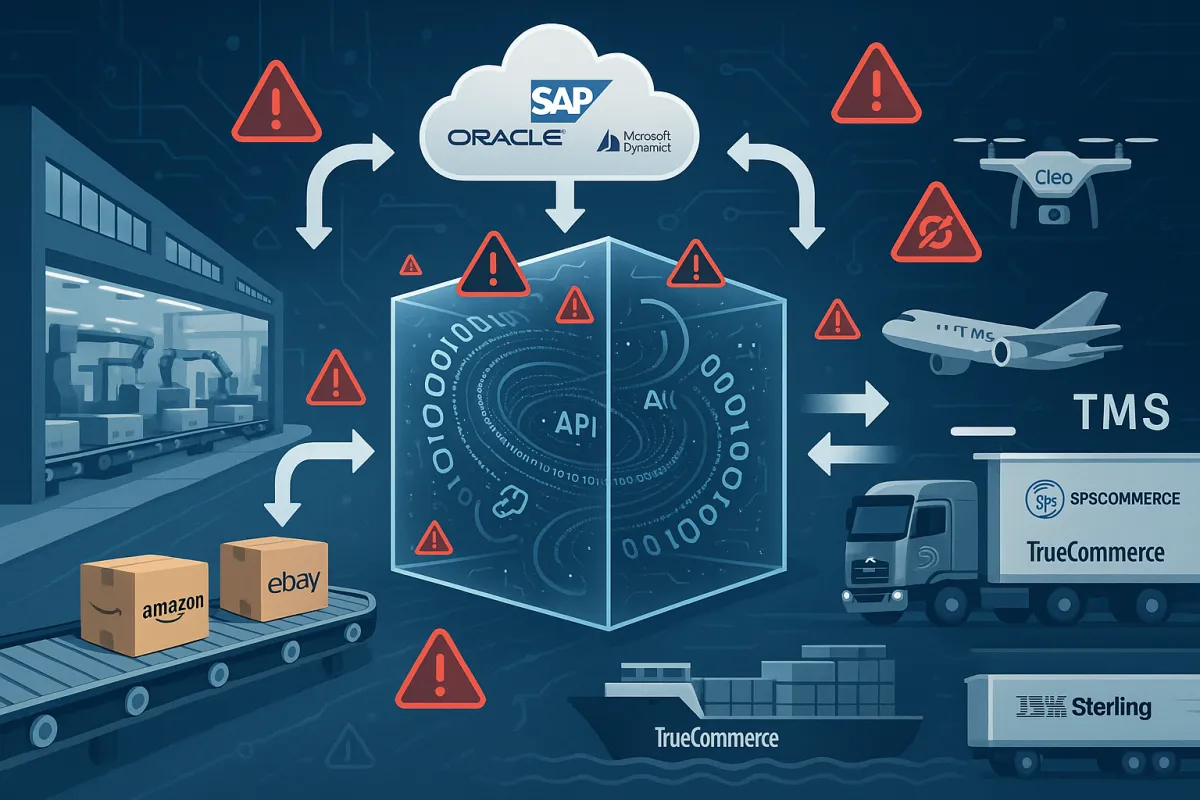

This convergence creates massive integration challenges. EDI issues during a TMS migration can usually be traced back to one of these root causes: Mapping mismatches: Every TMS platform structures its data differently. As research shows, up to 74% of integration failures stem from inconsistent data standards or faulty mappings between systems. When your ecommerce orders need to flow seamlessly into EDI transactions for suppliers and logistics providers, these mapping failures break everything.

The Hidden Integration Failures Breaking TMS Operations

Here's what most companies miss: What used to be a back-office EDI system running batch EDI transactions is now expected to support real-time, omnichannel commerce, tight EDI integration for supply chain visibility, and seamless integration with cloud business systems such as ERPs, WMS, TMS, ecommerce platforms, and 3PLs.

The problem gets worse during TMS upgrades. Because TMS and EDI systems are deeply connected, even minor mismatches between the two systems can lead to costly disruptions. Without precise mapping between new and existing fields, critical information can be dropped or misrouted.

When an enterprise grows and is looking to implement a new ERP or TMS, the switch will impact EDI with its trading partners. The average company that performs EDI has anywhere from 100-200 partners, and 400-500 maps—all of which will be impacted by the switch. This becomes a massive undertaking that most IT teams underestimate.

Manufacturing companies face additional complexity because ERP, TMS, and WMS tend to have very lightweight EDI processing. For example, a company may have a different communication software to support various protocols— scripts to complete EDI processing, scripts for database table lookups, or integration between different databases to pick up certain attributes and values.

The Real-Time Visibility Crisis in Hybrid Workflows

Traditional batch EDI processing creates dangerous visibility gaps when integrated with real-time ecommerce systems. Manufacturers that once depended on field sales teams and manual order entry are building digital sales environments where online orders automatically translate into structured EDI transactions for suppliers, logistics providers and key accounts.

The challenge? Your customers expect instant updates, but your EDI systems still process in batches. Real-time EDI updates — like EDI 214 shipment status messages — integrated into your TMS improve visibility of shipments for all parties, but most legacy systems can't handle this requirement.

Trading partners such as Walmart EDI, Target EDI, and Costco EDI now expect retailers, brands, and distributors to meet strict compliance rules, faster turnaround times, and more complex scenarios, such as dropship and marketplace fulfillment. These demands push companies beyond traditional EDI capabilities.

You end up with systems that work in isolation but fail when integrated. Common challenges include data synchronization issues, compliance with various EDI standards, handling diverse data formats, and cybersecurity concerns. Sound familiar?

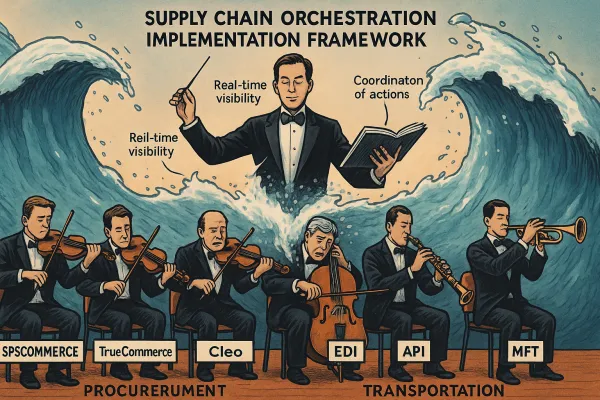

Building the Unified Integration Architecture

A defining development in 2026 is the emergence of hybrid integration models that combine traditional EDI document standards with modern APIs. This isn't about replacing EDI – it's about modernizing around it.

Successful companies focus on three core integration elements. First, ERP connectivity with native templates rather than generic file drops. If you're heavily invested in NetSuite, Dynamics 365, or Business Central, prioritize platforms with proven ERP-centric templates rather than being stuck with generic file drops.

Second, carrier API integration that goes beyond basic EDI messaging. Modern TMS platforms like Cargoson, MercuryGate, and Descartes offer different approaches. It offers direct API/EDI integrations with carriers across all transport modes (FTL, LTL, parcel, air, and sea freight), allowing you to compare rates, book shipments, and track imports and deliveries from a single platform.

Third, document format flexibility. Determining your systems of record (one or multiple ERPs, plus WMS/TMS, ecommerce, CRM) will determine the type of connectivity your platform will need to have in addition to core EDI functionality. Your architecture needs to handle XML, JSON, CSV, and traditional EDI formats without manual conversion.

The Data Mapping Automation Solution Framework

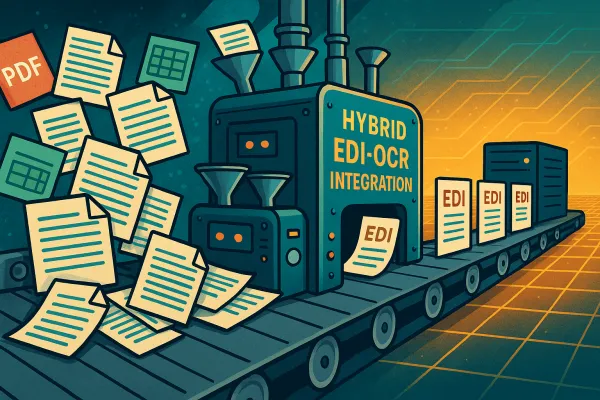

Manual data mapping creates the bottlenecks killing most integration projects. One of the challenges of EDI implementation is data mapping and transformation, where data from different systems must be translated into a common format. This process requires careful planning and expertise to ensure accurate data exchange.

The solution involves AI-powered mapping tools that eliminate repetitive manual work. AI can help to automate and streamline EDI-based processes in several ways, including: Automating data entry and conversion: AI can be used to automate the entry and conversion of EDI data into different formats, which can save time and reduce errors. Improving data quality: AI can be used to identify and correct errors in EDI data, which can help to improve the accuracy of B2B transactions.

Modern platforms like Orderful, Cleo, and newer entrants focus on automated mapping with reusable components. The fix begins with defining explicit, standardized data schemas and careful mapping of fields across systems. Middleware solutions or integration platforms help mediate data transformation.

Look for platforms offering automated field matching, exception handling workflows, and template libraries for common document types. Prebuilt retailer mappings and connectors (e.g., Walmart, Target, Costco, and hundreds of other trading partners) covering common X12 and EDIFACT messages reduce implementation time from months to days.

Testing and Validation Strategy for Unified Workflows

Integration testing prevents the failures that plague most hybrid deployments. Set up a testing environment. Use a staging environment that mirrors production to validate message flows, run simulations, and catch issues before they go live.

Your testing strategy should include document-level validation across all transaction types. Thorough EDI testing is essential to ensure that the integration functions as expected. Test Transactions: Simulate various transaction scenarios to identify any potential issues. User Acceptance Testing: Involve end-users in testing to ensure the system meets their needs.

Don't skip rollback procedures. APIs evolve. External providers may update or deprecate endpoints without warning. Your testing environment needs to catch these changes before they break production workflows.

Comprehensive testing covers trading partner simulation, end-to-end transaction flows, and performance under load. Conduct testing to ensure that the TMS EDI integration is functioning correctly and that data is being transmitted accurately between the systems.

Implementation Roadmap and Risk Mitigation

Phased implementation reduces integration complexity and business risk. To avoid that outcome, build your upgrade around these core steps: Audit your current EDI landscape. Start by identifying all existing EDI flows and documents tied to your TMS, including load tenders, shipment status updates, and invoices. Define data mapping early. Know how your new TMS structures data and how that maps to your existing EDI formats. This reduces the chance of mismatched fields or data loss midstream.

Start with pilot partner programs to validate your integration approach. Define your EDI document needs and the EDI transaction set requirements. Choose a compatible TMS and EDI integration solution that handles the transactions and secure connections you need. Have a plan for the project scope, timeline, and resources needed.

Consider your carrier integration strategy carefully. Solutions like Cargoson offer free carrier integrations, while others charge for each connection. Some TMS providers like Cargoson will integrate any carrier for you, for free (while others charge you for that and make you wait months or years).

Change management becomes crucial for teams transitioning from manual processes. EDI cuts these errors down dramatically, keeping your operations smooth and your customers happy. A tightly integrated TMS reduces manual work, brings reliable data, and supports real-time decision-making.

Performance monitoring should track both technical metrics and business outcomes. EDI can speed up business transactions by as much as 61%, but only when properly implemented and monitored.

The integration landscape will continue evolving, but companies that master unified B2B ecommerce-EDI workflows position themselves for competitive advantage. Rather than replacing EDI, companies are modernizing around it. Your integration strategy should embrace this hybrid approach while eliminating the data mapping failures that break TMS operations.