The Complete Guide to Real-Time EDI Processing: Eliminating Batch Delays for Instant Supply Chain Decision-Making in 2025

Most supply chain professionals still rely on batch processing for their EDI systems, treating data exchange like the old mail truck that arrives twice a day. Traditional EDI systems often relied on batch processing, which could delay critical business decisions, yet many organizations continue using these outdated approaches in 2025.

Think about what happens during those gaps. Your warehouse runs out of a key component at 2 PM, but your supplier won't know until the evening batch runs at 6 PM. They can't respond until their morning batch the next day. By then, you've lost 18 hours of potential production time. EDI operates on a batch processing model, meaning data updates occur at set intervals, rather than instantaneously. This delay can lead to outdated information, impacting decision-making and response times.

Understanding the Batch Processing Bottleneck in Traditional EDI Systems

Batch processing made sense in the 1980s when computing resources were expensive and network connections were unreliable. EDI systems collected transactions throughout the day, then processed them in large batches during off-peak hours. Batching is often used to group messages by document type; for example, you may want to send out a batch of purchase orders or a batch of invoices, to one or more trading partners.

Here's where batch processing creates problems today. EDI is not a real-time communication method; messages are batched into regular intervals. Your purchase order sits in a queue for hours. Your advance ship notice doesn't reach the warehouse until the next scheduled batch run. Meanwhile, customers are calling about delayed orders, and you're making decisions based on yesterday's inventory data.

The mailbox paradigm compounds these delays. Most EDI systems use a store-and-forward approach where documents wait in digital mailboxes until the next polling cycle. The limitation of this approach is that the batch delivery does not resume until the complete batch is processed by Oracle B2B. If one transaction in the batch has an error, the entire batch can be held up.

Consider a typical automotive supplier managing 200 purchase orders daily. In batch mode, morning orders might not process until evening, and evening orders wait until the next morning. That's a 12-hour minimum delay before any supplier can even see the demand. Add processing time, and you're looking at 24-36 hour response cycles for what should be immediate transactions.

The Real-Time EDI Revolution: What's Driving the Change

Market pressures are forcing companies to abandon batch processing delays. In 2025, real-time data exchange will become a must-have for businesses. Traditional EDI systems often relied on batch processing, which could delay data updates. With real-time EDI, you can get up-to-the-minute information on orders, shipments, and inventory.

The e-commerce explosion changed customer expectations. Amazon trained consumers to expect same-day updates on orders and shipments. B2B customers now demand similar responsiveness from their suppliers. Faster EDI is particularly valuable in industries like retail, logistics, and manufacturing, where timing is everything.

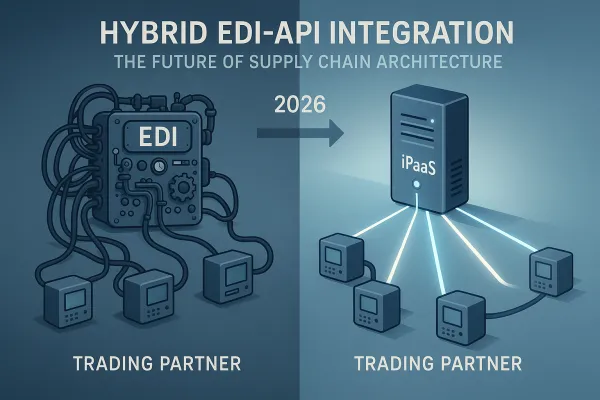

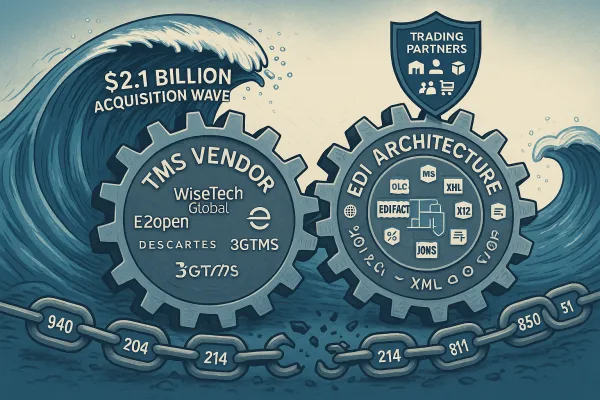

API integration is enabling this transformation. APIs are hailed for their real-time connectivity advantages, as they can connect with partner and SaaS applications quickly and efficiently. Modern EDI platforms are building API layers on top of traditional EDI standards, allowing for hybrid approaches that combine EDI's reliability with APIs' speed.

Cloud-native platforms have removed the infrastructure barriers that made real-time processing expensive. In 2025, modern EDI platforms have shifted toward (near) real-time EDI with optimized data streams. What once required dedicated servers and complex networking now runs on elastic cloud infrastructure that scales automatically.

Real-Time EDI vs. Batch Processing: The Technical Architecture Comparison

The technical differences go beyond speed. Batch systems collect data, validate it in groups, then transmit everything at once. Real-time systems validate and transmit each transaction immediately. Application Programming Interfaces (APIs) are a more modern solution that allows different software systems to communicate with each other in real-time. Unlike EDI, which relies on batch processing, APIs enable continuous data exchange, providing real-time visibility into supply chain operations.

Infrastructure requirements differ significantly. Batch processing can run on lower-bandwidth connections since it moves data in scheduled bulk transfers. Real-time systems need persistent, high-quality connections capable of handling constant traffic. The good news? Legacy batch processing or request/response models often cause costly delays in a world where market conditions shift by the minute.

Processing speeds show dramatic differences. Batch systems measure performance in hours between cycles. Real-time systems measure in milliseconds per transaction. A typical batch EDI cycle might process 1,000 transactions in 30 minutes. The same real-time system processes each transaction in under 2 seconds as it arrives.

Leading TMS solutions like Cargoson, MercuryGate, and Transporeon now support real-time processing modes. These platforms can receive shipment updates, process them immediately, and push notifications to all relevant parties within seconds of the original event.

Hybrid Approaches: Getting the Best of Both Worlds

Smart implementation doesn't always mean choosing one approach over another. According to them, while "EDI is ideally suited for batch processing of mission-critical transactions like financial documents and periodic updates, APIs enable real-time data exchange for proactive decision-making to drive competitive advantage."

Use batch processing for high-volume, non-urgent transactions like daily inventory reports or weekly payment files. Deploy real-time processing for urgent notifications like shipment delays, quality issues, or stockouts. This mixed approach lets you optimize costs while ensuring critical information flows immediately.

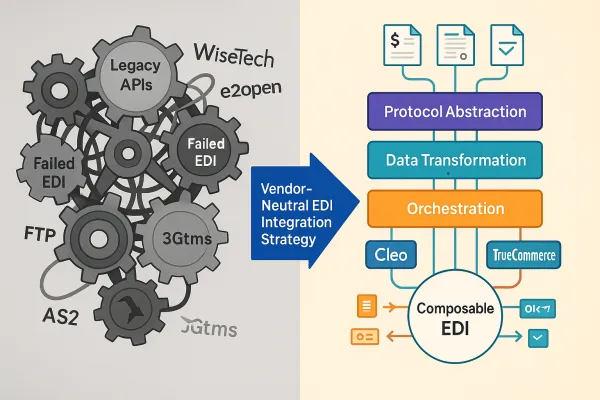

A connected strategy bridges both worlds. Instead of completely throwing out one technology in exchange for another, integrating the best of EDI and API capabilities allows businesses to stay rooted in an industry-standard technology they know works while expanding its capabilities to keep up with a rapidly shifting technological landscape. Companies need to support both a core set of EDI transaction types and API capabilities or risk missing out on important opportunities to drive revenue, growth and competitive differentiation.

Business Benefits of Real-Time EDI Processing

Immediate decision-making capabilities transform supply chain operations. When your supplier sends a shipment delay notification at 10 AM, you can notify customers, adjust production schedules, and source alternatives by 10:15 AM instead of discovering the delay during the evening batch run. Key benefits of real-time data exchange with EDI include: Immediate access to critical data, which reduces delays. Enhanced inventory control with real-time stock updates. Faster order processing and delivery times.

Supply chain visibility improvements ripple through every process. When real-time data exchange is implemented through EDI, key players in the supply chain, such as suppliers, manufacturers, distributors and retailers, can receive updates about inventory levels, shipping schedules and payment status promptly. This real-time visibility helps reduce lead times, improve inventory management and streamline the decision-making process.

Customer satisfaction scores improve measurably. Companies implementing real-time EDI report 25-40% reductions in customer complaints about delivery visibility. When customers can track orders in real-time and receive proactive notifications about changes, their satisfaction increases even when problems occur.

Cost reduction comes from faster processing cycles. EDI allows enterprises to cut processing time remarkably through automation, speeding up business cycles. EDI order processing substituting for traditional order-to-shipment cycles, in particular, can be cut by 50 percent to 60 percent. Reduced processing time means lower labor costs, fewer errors, and faster cash cycles.

Implementation Roadmap: Migrating from Batch to Real-Time EDI

Assessment starts with mapping your current data flows. Document every batch process, its frequency, and business impact. Identify which transactions truly need real-time processing versus those that can remain batched. High-value, time-sensitive transactions like shipment notifications and order confirmations typically become real-time priorities.

Technology stack requirements include persistent connectivity, real-time validation engines, and event-driven architectures. Your infrastructure needs to handle continuous data streams rather than periodic batch loads. Cloud platforms make this easier by providing auto-scaling compute resources and managed messaging services.

Partner onboarding becomes more complex with real-time systems. Each trading partner needs to support immediate transaction processing or at least acknowledge receipt quickly. Start with your largest, most technically capable partners before expanding to smaller suppliers who might need more support.

Integration with existing ERP systems requires careful planning. SAP, Microsoft Dynamics, and Oracle all support real-time interfaces, but you'll need to configure them properly. Most ERP systems can consume real-time EDI data through web services or API calls, but you may need middleware to handle the translation and routing.

Provider solutions from Cleo, TrueCommerce, and SPS Commerce now offer real-time capabilities. For transportation management, platforms like Cargoson provide real-time shipment tracking and automated notifications that integrate directly with EDI workflows.

Choosing the Right EDI Provider for Real-Time Processing

Evaluation criteria should include latency measurements, not just throughput rates. Ask providers for specific performance metrics: How quickly can they process a 100-line purchase order? What's their average response time for acknowledgments? Can they guarantee sub-second processing for priority transactions?

Provider comparison reveals significant differences between managed services and self-service platforms. Managed services typically offer better SLA guarantees for real-time processing but cost more. Self-service platforms give you more control but require internal expertise to maintain real-time performance.

Integration capabilities with TMS solutions matter significantly. Look for providers that can connect seamlessly with leading transportation management systems. Cargoson alongside industry leaders like MercuryGate and Oracle Transportation Management provide APIs that integrate well with real-time EDI platforms.

Overcoming Common Implementation Challenges

Trading partner compatibility creates the biggest hurdle. Not all partners can handle real-time transactions immediately. Create migration phases that gradually move partners from batch to real-time processing. Start with large partners who have technical capabilities, then provide support for smaller suppliers.

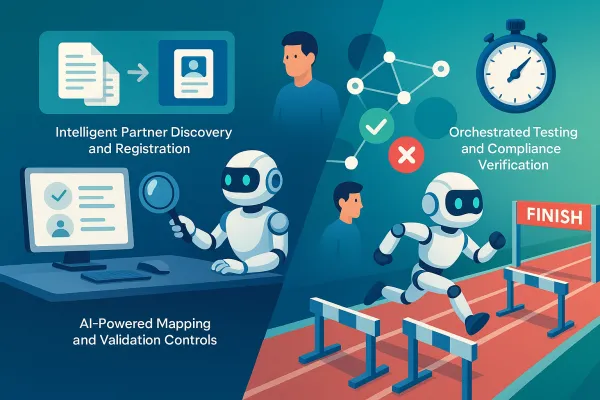

Data quality becomes more critical in real-time systems. Batch processing gave you time to fix errors before transmission. Real-time systems need immediate validation. AI and machine learning have redefined EDI integration. These technologies correct data anomalies and offer predictive analytics for improved efficiency. Best Practice: Incorporate AI-driven tools to monitor EDI transactions and automate error handling, significantly reducing reliance on manual processes.

Security considerations multiply with real-time systems. Every transaction creates a potential attack vector. Implement strong encryption, authentication, and monitoring. The increasing cyber threats make securing EDI transactions more crucial than ever. Implementing advanced encryption and blockchain technologies ensures data integrity and security. Best Practice: Apply advanced encryption protocols and consider blockchain for a transparent, tamper-proof transaction ledger.

Change management requires different skills. Your team needs to shift from monitoring batch schedules to managing continuous data flows. Train staff on real-time monitoring tools, exception handling procedures, and immediate response protocols. The skills needed for real-time operations differ significantly from batch processing expertise.

Future-Proofing Your Real-Time EDI Strategy for 2025 and Beyond

AI and ML integration opportunities are expanding rapidly. In 2025, Electronic Data Interchange (EDI) is no longer just a tool for exchanging documents—it's a foundational enabler of enterprise automation and artificial intelligence. By providing structured, standardized, and high-quality data, EDI fuels the data pipelines that AI systems rely on to deliver insights and drive intelligent decision-making.

Predictive analytics powered by real-time EDI data will become standard. This structured data is ideal for training machine learning models, enabling predictive analytics, demand forecasting, and anomaly detection. With EDI feeding real-time data into ERP and logistics systems, businesses can automate entire workflows—from order processing and inventory updates to invoice reconciliation and shipment tracking—without human intervention. AI systems can analyze EDI data streams to identify trends, optimize procurement strategies, and flag potential disruptions.

IoT data integration will connect physical and digital supply chains. Connecting Internet of Things (IoT) devices like smart sensors and RFID tags with EDI helps businesses track shipments, monitor inventory, and update data in real-time. This improves supply chain visibility by providing accurate, up-to-the-minute information on product location and condition — especially useful in industries like pharmaceuticals and logistics.

Blockchain for enhanced security and transparency will mature. Best Practice: Apply advanced encryption protocols and consider blockchain for a transparent, tamper-proof transaction ledger. Real-time EDI transactions recorded on blockchain create immutable audit trails, making supply chain fraud nearly impossible while enabling instant verification of transaction authenticity.

The transition from batch to real-time EDI processing isn't just a technical upgrade—it's a competitive necessity. Real-time data exchange allows you to make informed decisions faster. With real-time EDI, you can respond to changes in the market more quickly. For example, if an unexpected delay occurs in your supply chain, you can make adjustments in real-time. This agility gives you a competitive edge. Companies that continue relying on batch processing will find themselves constantly reacting to supply chain events rather than proactively managing them.

Start your migration planning now. Identify your most critical data flows, evaluate your technology infrastructure, and begin conversations with your key trading partners. The companies that successfully implement real-time EDI processing in 2025 will set the standard for supply chain responsiveness in the years to come.