The Complete TMS Integration Cost Analysis: EDI vs API vs Hybrid Approaches - Hidden Expenses, ROI Calculations, and Vendor Comparisons for 2025

Your EDI system just broke three trading partner connections after upgrading your TMS last weekend. The finance team is breathing down your neck about failed ASN transmissions. Sound familiar? Carrier connectivity represents one of the largest hidden cost areas. Some TMS providers offer published APIs for carrier integration, but carriers may charge shippers for establishing these connections. While carriers can easily join platforms through portals, requesting completely new carrier API/EDI integrations is complex and costly - and your weekend just became a lot longer.

This scenario plays out across European and North American operations monthly. Companies pour resources into TMS EDI integration cost calculations, only to discover their budget missed the real expenses that surface during implementation. EDI integrations may take several months, whereas, API integrations can take a matter of weeks, if not days, but the devil lies in the details that vendors don't discuss during sales presentations.

The $3M Hidden Cost: Why 53% of Enterprises Struggle

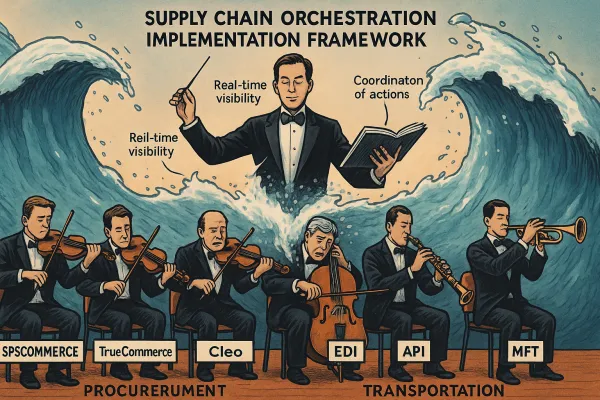

The convergence of APIs and EDI presents opportunities but also highlights the need for cross-training between the retiring EDI experts and the next generation to maximize ROI. Here's what the research reveals about TMS integration failures:

Labor costs dominate the hidden expense category. Many carriers aren't willing or able to create API connections, and even when they are, they'll charge integration costs to you. European shippers working with 20-30 regular carriers face substantial connectivity expenses that vendors rarely discuss during initial demos. A mid-sized manufacturer typically manages 100-200 trading partners with 400-500 maps - all impacted when switching TMS platforms.

Downtime costs multiply quickly. EDI (Electronic Data Interchange) $3995 Setup plus $1700 per trading partner (your customer) and $1300 per EDI Document type (204 Load Tender). Plus $300/month for up to 1000 transactions. $0.10 per message thereafter represents just the tip of the pricing iceberg. When your EDI connections fail during peak shipping periods, the revenue impact compounds hourly.

Complete Cost Breakdown: EDI vs API vs Hybrid Integration Models

The pricing landscape has shifted dramatically in 2024-2025. Manufacturers need tight links between shop-floor systems and external partners. Look for sub-USD 500/month packages that bundle pre-mapped templates for orders (850), inventory (846), and shipments (856), with the option to plug into a cloud hub or gateway.

EDI-Only Integration: Traditional Approach Cost Analysis

Traditional EDI providers have moved beyond simple transaction-based pricing. The market now offers two distinct models: per-transaction fees that scale with volume, and partner-based pricing that allows unlimited transactions for a flat rate. This shift reflects the reality that 85% of supply chain transactions are still managed through EDI.

Implementation costs break down predictably: base licensing (20-30% of total), implementation services (25-40%), carrier integration (15-25%), customization and training (10-20%), and ongoing support (15-20%). For a typical mid-sized operation, expect initial setup costs between $50,000-150,000, with monthly operational expenses of $2,000-8,000 depending on transaction volumes and partner count.

The upgrade challenge creates the biggest hidden cost. When switching TMS platforms, your existing EDI maps become obsolete. Switching gets harder once you look at the network math. Hundreds of supplier and carrier maps already exist. Re-mapping each one and retesting both sides costs money and focus.

API-First Integration: Modern Approach Investment

Integration through APIs is generally less complex than EDI integrations. Public APIs are built for reusability. Once a public API is available, anyone with credentials can build solutions to leverage that API, whereas EDI requires unique data mapping for each integration.

Development resources dominate API costs. Unlike EDI's predictable fee structures, API implementations require significant upfront development investment. APIs can be set up and configured pretty easily by your IT department or any tech-savvy analyst. EDI generally needs expensive, specialized consultants to set up or change anything.

Real-time capabilities come with infrastructure costs. With cloud-based solutions, API allows transportation management systems (TMS) to transmit data in less than a second, but this speed requires robust hosting, monitoring, and security infrastructure. Budget $100-500 per month per API endpoint, plus development costs of $15,000-50,000 per integration depending on complexity.

Security requirements add another layer. Version control – keep a change log and stick to numbered releases. Access & security – give every partner its own secure token; no shared passwords requires dedicated security infrastructure and ongoing maintenance.

Hybrid EDI-API: Best of Both Worlds Analysis

You wouldn't choose one over the other in many cases — you would choose both. Several recent trends have driven companies to create hybrid integration solutions that leverage EDI and APIs.

The hybrid approach delivers optimal cost-effectiveness when implemented strategically. Going "API-only" promises real-time updates and cost savings, but the reality is rarely binary. Time-sensitive events like dock appointments, GPS pings and on-hand stock benefit from API speed, while invoices and customs forms sit comfortably in EDI's structured format.

Adopt a Hybrid Approach: Combining EDI via API using EDI2XML REST API for standardized EDI, along with batch processing with APIs for real-time updates gives businesses the flexibility to meet various demands without sacrificing operational efficiency. This approach typically costs 20-30% more than single-method implementations but delivers significantly better operational flexibility and partner satisfaction.

TMS Vendor Integration Capabilities and Costs Compared

The competitive landscape reveals significant differences in integration approaches and associated costs. Alpega connects to 80,000+ European transport professionals, MercuryGate offers broad North American coverage, and Cargoson focuses on European API/EDI connections.

Enterprise TMS Solutions: MercuryGate, Descartes, E2open Analysis

The software is available on a subscription basis, with monthly costs starting at $500 for 1 user. For 10 users, the price is $4,500 per month, and for 100 users, it is $40,000 per month for MercuryGate's platform. MercuryGate TMS uses a subscription license pricing model based on number of users or transactions. Additional fees apply for ancillary services like implementation, training and custom integrations.

Enterprise solutions excel at handling complex integration scenarios but require substantial investment in professional services. Access to over 10,000 carrier connections via EDI and API, though many are through standard EDI formats that carriers must implement. Adding new carriers requires significant setup time and may involve additional costs with MercuryGate's approach.

Hidden costs emerge during customization phases. Custom code development, workflow modifications, and integration updates accumulate over the system lifecycle. Advanced TMS solutions support diverse transportation scenarios requiring tailored configurations, while basic systems with rigid workflows may fail to accommodate specific needs.

Mid-Market Solutions: Alpega, nShift, Cargoson Comparison

Transaction-based with options for shipper-pay or carrier-pay models, estimated at €500-€5,000/month depending on shipment volume characterizes Alpega's pricing approach. Connected to 80,000+ transport professionals across Europe. In 2025, they launched Alpega MultiParcel which also connects to over 1,000 parcel carriers.

Mid-market solutions prioritize ease of implementation over extensive customization capabilities. While carriers can easily join the platform through their portal, requesting completely new carrier API/EDI integrations is more complex and costly. Alpega typically doesn't build custom carrier integrations themselves but acquires companies with existing connections or provides standard EDI interfaces that carriers must implement.

Cargoson builds true API/EDI connections with carriers, not just accounts in software or standardized EDI messages that carriers must implement themselves. This approach reduces the ongoing integration costs that plague many implementations.

Cargoson and other modern European TMS providers often include implementation support in their pricing models, contrasting with traditional enterprise vendors who separate these services. This bundled approach provides better cost predictability for mid-market shippers.

ROI Framework: Calculating True Integration Value

Calculating TMS integration ROI requires understanding both quantifiable savings and operational improvements. By leveraging these differentiators, MercuryGate TMS can help organizations increase shipment visibility, reduce freight costs by 5-10%, improve dock utilization by 20% and accelerate invoice processing by 80%. Ultimately this leads to lower overhead, reduced stockouts and better customer service.

Methodology starts with baseline measurement. Document your current manual processes: hours spent on data entry, frequency of communication errors, time from order to shipment visibility, and carrier onboarding timelines. Modern transport tender management through TMS platforms can reduce procurement cycle times by 60% while delivering measurable cost savings.

Quantifiable benefits include direct cost reductions and efficiency gains. Speed – Messages travel in seconds instead of hours, and trigger pick tickets sooner. Error handling – One bad record can be fixed on the spot. No whole-file resend. Visibility – APIs refresh dashboards in seconds, giving teams time to adjust labor, inventory, or routing before costs mount.

Payback periods vary significantly by implementation approach. EDI-only implementations typically achieve payback in 12-18 months through reduced manual labor and error correction. API-first approaches require 18-24 months due to higher upfront development costs but deliver superior long-term operational efficiency. This cross-training can feed into a true API EDI integration that yields a positive ROI now and for the future.

2025 Implementation Roadmap: Step-by-Step Cost Planning

Start with partner readiness assessment. Partner readiness – confirm each carrier or supplier can connect to the new channel or keep sending a backup EDI file. Cut-over plan – run a short pilot and keep the old file feed open until loads flow smoothly.

Phased implementation reduces risk and spreads costs. Begin with your highest-volume trading partners using proven EDI connections, then gradually add API capabilities for real-time visibility and customer-facing applications. Strategic Planning – Assess current systems – Define clear objectives – Set realistic timelines – Allocate resources effectively – Plan for scalability.

Budget for ongoing evolution. "The push is going to continue to be digital, digital, digital." Fleets and shippers must prepare for continuous adaptation. Future-Proof Your Integration Strategy: As more businesses transition to the cloud and leverage APIs, make sure your systems are agile and adaptable to new technologies.

Your TMS EDI integration cost planning should account for both immediate implementation expenses and long-term operational flexibility. The companies succeeding in 2025 aren't choosing between EDI and APIs - they're building hybrid infrastructure that leverages both technologies strategically. Whether you select enterprise solutions like MercuryGate, mid-market options like Cargoson, or develop custom integrations, the key lies in understanding your true total cost of ownership and building systems that adapt as your business grows.