The Critical Batch-to-Real-Time EDI Migration Crisis That's Breaking 70% of TMS Integrations: Your Complete Solution Framework to Bridge Legacy Systems and Modern API Requirements in 2026

MercuryGate has struggled with what becomes clear when you dig into implementation experiences. Many vendors don't support EDI functionality out of the box and have duct tape and rubber banded solutions together to make EDI work. That's exactly the kind of fragile foundation that collapses during the transition to real-time processing.

The numbers behind this crisis tell a troubling story. Every TMS platform structures its data differently, and without precise mapping between new and existing fields, critical information can be dropped or misrouted. Older EDI connections often rely on protocols like FTP or AS2, and if the new TMS doesn't support those methods differently, message delivery can fail entirely.

The Technical Incompatibility Problem

Here's where most TMS implementations hit the wall. What used to be a back-office EDI system running batch EDI transactions is now expected to support real-time, omnichannel commerce and tight EDI integration for supply chain visibility. The fundamental issue isn't just about speed. Files move on a fixed schedule, so updates can take hours to reach the next system, while modern supply chains demand instant visibility.

Think about this scenario: Your batch EDI system processes overnight files from carriers at 2 AM. But your API-connected customers expect real-time status updates throughout the day. When a carrier misses a cut-off, the TMS should instantly re-issue the load without a planner's phone call, and customer portals should show actual dock departure, not yesterday's batch ASN time stamp.

Data Synchronization Chaos

The real pain point emerges in data synchronization between batch intervals and real-time API feeds. If EDI and ERP are "loosely coupled," you'll end up with manual rekeying and reconciliation, which defeats the purpose of automation. TMS platforms like Manhattan Active face these challenges differently than modern API-first solutions, but the core problem persists: batch systems weren't designed to coexist with real-time data flows.

Major TMS Vendor Approaches to the Transition Challenge

Leading vendors have taken markedly different approaches to solving the batch-to-real-time transition. Descartes offers access to over 10,000 carrier connections via EDI and API, though many are through standard EDI formats that carriers must implement. Compare this to newer platforms like Cargoson, which builds true API/EDI connections with carriers, not just accounts in software or standardized EDI messages that carriers must implement themselves.

MercuryGate's response has been to offer electronic data interchange with customers and trading partners plus APIs to integrate seamlessly with other enterprise systems, with main modules including EDI and API connectivity. However, the integration story remains complex. Their API connection works in tandem with traditional EDI to help automate shipment lifecycles with no disruption to current processes.

The Enterprise Integration Complexity Factor

What many vendors don't openly discuss is the scope of integration complexity. Integrating EDI with TMS can be technically challenging, especially for organizations with outdated systems or limited IT resources, often requiring businesses to invest in middleware solutions to bridge the gap between legacy systems and modern EDI requirements.

Consider this reality check: when you're managing 100-200 trading partners, each with different requirements, adding new carriers requires significant setup time and may involve additional costs. Manhattan's approach is telling here. They rely on EDI/API connections and partners like MetaPack for parcel carriers, with adding new carriers often being complex and costly, requiring third-party integration partners.

Operational Impact and Cost Analysis Framework

The hidden costs of maintaining batch systems extend far beyond licensing fees. The initial investment for integration can be substantial, although it is often recouped through long-term savings. But that's just the beginning. High-end enterprise pricing typically starts at $30,000-$100,000 annually, with implementation costs sometimes reaching six figures.

More concerning are the operational disruption costs. Even minor mismatches between TMS and EDI systems can lead to costly disruptions, and when a TMS system is swapped out or reconfigured without an EDI continuity plan, the result is often delays, chargebacks, or failed deliveries which can damage partner relationships.

The resource allocation challenge becomes particularly acute during migration periods. Migration teams often lack a staging environment that accurately mirrors production, making it more challenging to identify issues before going live. Traditional platforms like Blue Yonder and E2open face these challenges differently than solutions with built-in testing environments.

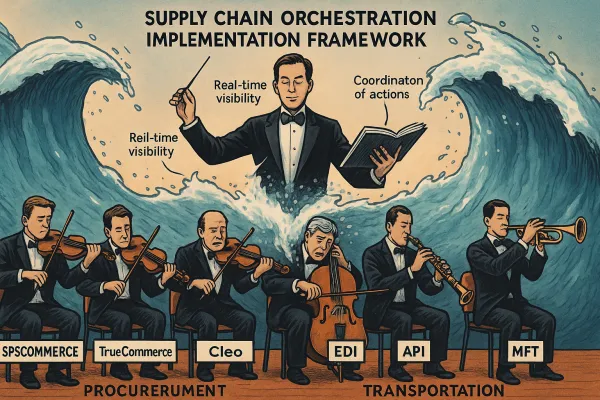

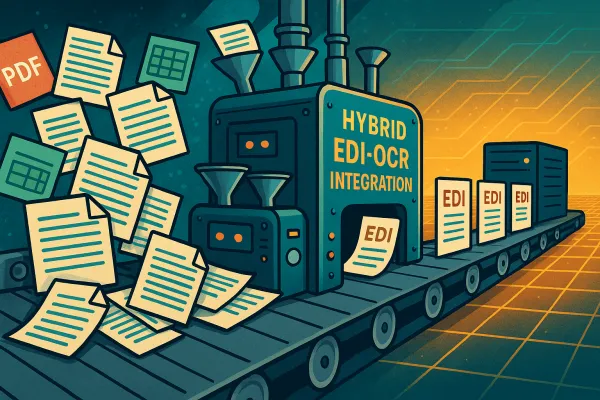

Hybrid Integration Solution Architecture

The most successful approach emerging in 2026 involves strategic document separation. Moving status-heavy documents (163, 214, appointment notes) to API is optional and partner-by-partner, while inventory-centric documents (943, 856, 945, 846) keep riding EDI until your ERP and trading partners are ready for a broader API leap.

This hybrid architecture addresses the core incompatibility by running parallel queues. Some add a middleware gateway where a cloud service takes in an API call and quietly converts it to X12 or EDIFACT (and back again) so every partner sees its preferred format. Modern TMS solutions including Cargoson alongside established players like 3Gtms/Pacejet and Alpega are building these capabilities natively.

Implementation Best Practices and Risk Mitigation

The most critical factor for successful migration is continuity planning. As with ERP transitions, a TMS upgrade should include a clear continuity plan for EDI connections. The assessment process should cover multiple dimensions. Make sure your trading partners are on board and their systems are compatible with your EDI setup, choose the right EDI standards based on your industry and partner requirements, and run thorough tests before going live.

Testing becomes especially complex with hybrid architectures. A reliable EDI deployment requires full validation across your internal systems and trading partners, but with some vendors, testing often stops at their software boundary, leaving your ERP, TMS, and other backend systems unvalidated, and that gap can lead to post-launch issues, chargebacks, and costly downtime.

Future-Proofing Your TMS-EDI Strategy for 2027 and Beyond

The market is moving toward API-integrated EDI architectures that enable real-time transaction processing. Modern platforms offer real-time visibility and exception handling across all trading partners and support use cases such as EDI for supply chain management by helping companies replace legacy translators with cloud-scalable, user- and API-friendly platforms.

Cloud-native deployment is becoming essential. A cloud-based system offers better scalability, real-time monitoring, and fewer on-premise maintenance headaches, with built-in data validation to spot and fix errors before they cause failed transmissions, and fast trading partner onboarding that shouldn't require custom development.

The next generation of TMS platforms will need to support this dual reality: maintaining EDI for compliance while enabling API innovation for competitive advantage. Look for an EDI integration platform that can mix EDI with non-EDI formats (XML, JSON, CSV) and convert seamlessly between them, so you can automate invoices or order flows regardless of whether partners use classic interchange standards or modern APIs.

Success in 2027 will depend on choosing platforms that handle this transition gracefully. While traditional solutions struggle with the technical debt of legacy architectures, modern TMS platforms including multi-carrier shipping solutions are building hybrid capabilities from the ground up. The companies that solve this challenge will gain significant competitive advantage over those still fighting yesterday's integration battles.