The Critical EDI Testing-to-Production Gap That Causes 90% of Post-Launch Failures: Your Complete Validation Framework to Prevent Costly Disruptions and Ensure Seamless Go-Live Success in 2026

Last quarter, a Fortune 500 manufacturing company faced a €2.5 million loss from EDI pricing discrepancies after their "successful" testing missed critical edge cases in production. The testing team had validated everything perfectly in their controlled environment, yet when transactions hit the real world, 66% of businesses lose up to €500,000 yearly from pricing errors alone. This failure pattern affects 85% of businesses that utilize EDI for B2B transactions, where comprehensive testing becomes the difference between operational success and financial disaster.

EDI testing production failures aren't just technical hiccups—they represent systematic gaps that cause documented business impact. During tough economic times, a 5% data error rate is the difference between business success or failure, making proper testing validation critical for maintaining competitive advantage.

The Hidden $500K Crisis: Why 90% of EDI Projects Fail After "Successful" Testing

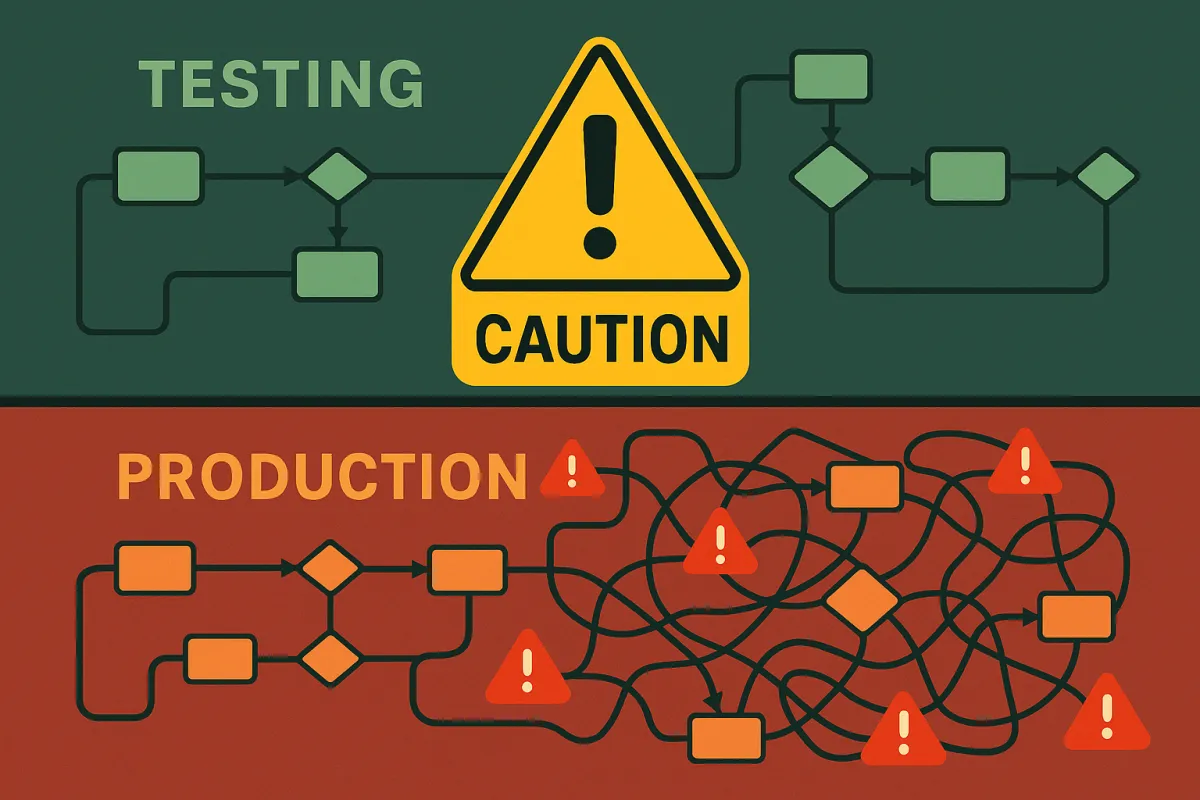

The problem isn't your testing team or your EDI platform. 40% of businesses struggle with software integration during EDI implementation, but the deeper issue lies in the fundamental mismatch between testing scenarios and production reality. Most EDI testing focuses on ideal conditions: perfect data formats, predictable transaction volumes, and controlled partner variations.

Production tells a different story. Amazon changed their 'carton level information ASN/SSCC process' which if not adhered to "currently incurs a chargeback at £0.05, €0.06, $0.10 per SKU received". For a shipment of 48 units, that's £2.40 in penalties—multiplied across thousands of transactions, these seemingly minor validation failures create substantial financial impact.

EDI errors aren't just a minor inconvenience; they directly affect your bottom line. A single incorrect invoice can trigger a domino effect of delayed payments, strained relationships with suppliers, and a backlog in your accounts receivable department. The cascading effects compound rapidly: what starts as a formatting error becomes operational disruption, supplier relationship damage, and measurable revenue loss.

The statistics reveal the true scale: Successful EDI implementation can reduce costs over 90% compared to manually processing business transactions, but only when testing properly validates production scenarios. When it doesn't, companies face the inverse—multiplied costs from automation that creates rather than solves problems.

The 7 Critical Testing Gaps That Doom EDI Go-Lives

Understanding why EDI projects fail requires examining specific gaps between testing assumptions and production reality. Each gap represents a different category of failure that testing teams routinely miss.

Gap 1: Testing Ideal Scenarios vs. Real-World Data Variations

Your test data looks perfect—clean formatting, complete fields, standard code sets. Production data includes partner-specific variations, historical formatting inconsistencies, and edge cases that accumulated over years of business relationships. Studies suggest that up to 5% of all manually entered invoice data is typed incorrectly. This is a huge handicap for any company aiming to be more efficient and customer-focused.

Gap 2: Missing Cross-System Integration Validation

Testing often validates EDI messages in isolation without confirming how they integrate with ERP systems, warehouse management platforms, or financial applications. If your process changes, say your ERP is updated, or a trading partner modifies their document structure, the entire flow can break. This rigidity forces businesses into endless cycles of development and testing, just to make small adjustments.

Gap 3: Insufficient Volume and Performance Testing

Standard testing validates message correctness but ignores volume scenarios. Cloud-native platforms usually handle spikes better because they scale automatically. So, during a busy period, like Black Friday or quarter-end, you won't see delays or failed messages just because volume increased. Traditional testing misses these critical stress scenarios.

Gap 4: Poor Error Handling and Exception Testing

Most legacy EDI systems integrations leave you in the dark when something goes wrong. A file fails, but you're not told why, or worse, you find out after your customer does. There's no intuitive dashboard to track status, no alerting system to flag issues in real time. Testing rarely validates how systems behave during partial failures, network disruptions, or partner system outages.

Gap 5: Inadequate Business User Validation

Technical testing confirms that messages are syntactically correct but often skips business logic validation. Does the system properly handle volume discounts? Can it manage partial shipments correctly? These business scenarios require validation by users who understand operational workflows, not just technical specifications.

Gap 6: Missing Compliance Edge Case Testing

Businesses that fail to stay compliant with EDI standards face operational inefficiencies and potential legal issues. Testing often validates standard compliance scenarios but misses partner-specific requirements, regulatory updates, or industry-specific validation rules that emerge in production.

Gap 7: Lack of Production-Like Environment Testing

Most testing happens in sanitized environments that don't replicate production network conditions, security constraints, or system integrations. This creates false confidence when clean test results don't translate to production reliability.

Modern platforms like Cargoson, TrueCommerce, and SPS Commerce address some of these validation challenges through enhanced testing frameworks and production simulation capabilities, but implementation teams still need structured approaches to bridge testing-production gaps.

The Production Reality Check: What Testing Never Reveals

Production environments reveal complexities that testing scenarios cannot fully replicate. Trading partner data variations break systems in unexpected ways—a supplier suddenly changes their qualifier codes, or a major retailer updates their validation rules without comprehensive notification.

Peak volume scenarios create failure patterns invisible during standard testing. Jitterbit maintains the highest level of performance and reliability and handles production environments that process over 120 million records per day without performance-related issues, but reaching these performance levels requires testing that simulates actual production loads, not theoretical maximums.

Integration failures with ERP systems become apparent when real business processes stress the connections. SAP updates, Oracle patches, or NetSuite configuration changes can disrupt EDI flows that tested perfectly in isolation. Miscalculating the supply chains' intricacies can derail a project from the start. Remember, EDI encompasses multiple sets of standards and transmission protocols. The solution that companies pick must align with the amount of data being onboarded and requirements of a business.

Security and compliance issues emerge in live environments where network configurations, firewall rules, and authentication requirements differ from testing setups. When sending data, two parties must exchange and agree to send data over agreed protocols. Mistakes can be made when setting this up, e.g., firewalls left closed, or encryption details inaccurate or incorrect. This will prevent the data from being sent and cause delays in the supply chain.

Case Study: The $2.3M Amazon EDI Compliance Failure

A major consumer electronics supplier tested their Amazon EDI integration thoroughly, validating message formats, transmission protocols, and basic compliance requirements. Testing showed 100% success rates across all scenarios.

Three months into production, Amazon updated their Advanced Ship Notice requirements, adding new mandatory fields for carton-level tracking. The supplier's EDI system continued processing orders, but Amazon changed their 'carton level information ASN/SSCC process' which if not adhered to "currently incurs a chargeback at £0.05, €0.06, $0.10 per SKU received".

Over six months, processing 4.6 million units with missing carton data resulted in $460,000 in direct chargebacks. Factor in operational costs to identify the issue, implement corrections, and manage the backlog of affected shipments, and total recovery costs exceeded $2.3 million. The failure wasn't technical—their EDI system functioned perfectly. The gap was between testing scenarios and evolving production requirements.

The Complete Testing-to-Production Validation Framework

Addressing EDI testing gaps requires a systematic approach that bridges the validation gap between testing environments and production reality. This framework layers multiple testing phases to catch issues before they impact business operations.

Phase 1: Enhanced Unit Testing with Edge Case Scenarios

Expand standard message validation to include realistic data variations. Create test data that reflects actual partner quirks—incomplete address fields, non-standard date formats, and coding variations that accumulate over years of business relationships. One of the most important aspects of your EDI implementation should be its capability to validate the composed EDIs against the partner specified set of rules and ensure that they are compliant before sending it to the partner. Also in the case of a validation failure, the EDI implementation should be able to indicate the exact problem to the user.

Phase 2: Integration Testing with Production-Like Data

Validate EDI flows within complete system environments that mirror production configurations. Test how messages flow from initial receipt through ERP processing, inventory updates, and financial posting. Use anonymized production data to ensure realistic complexity without compromising sensitive information.

Phase 3: Volume and Stress Testing Protocols

Simulate peak transaction volumes and concurrent processing scenarios. Test system behavior during batch processing windows, month-end volume spikes, and seasonal peaks. Cloud-native platforms usually handle spikes better because they scale automatically. So, during a busy period, like Black Friday or quarter-end, you won't see delays or failed messages just because volume increased.

Phase 4: Business Process Validation

Engage business users in testing scenarios that reflect actual operational workflows. Validate complex business rules, exception handling, and approval processes that technical testing cannot adequately cover.

Phase 5: Compliance and Security Verification

EDI testing includes verifying that sensitive data is properly handled, encrypted, and protected, which is essential for compliance with data protection regulations like GDPR or CCPA. Proper testing establishes a clear audit trail of transactions, which is crucial for compliance audits and dispute resolution.

Phase 6: Production Parallel Testing

Run new EDI implementations in parallel with existing systems, comparing results and identifying discrepancies before cutover. This phase catches issues that emerge only under actual production conditions and business workflows.

Modern platforms like TrueCommerce, SPS Commerce, Cargoson, and Cleo provide tools to support this comprehensive testing approach, though implementation teams must still design testing scenarios that reflect their specific operational requirements.

Advanced Testing Tools and Automation Strategies for 2026

AI-powered testing validation represents the next evolution in EDI testing capabilities. According to McKinsey, AI-powered forecasting may minimize mistakes by 30 to 50% in supply chain networks, and similar improvements apply to EDI testing when AI analyzes historical failure patterns to predict potential issues.

Automated edge case generation uses machine learning to create test scenarios based on production data patterns. These tools identify data variations that human testers might miss, generating test cases that reflect the actual complexity of partner data rather than idealized test scenarios.

Real-time monitoring and alert systems bridge the gap between testing and production by providing continuous validation of live transactions. Look for tools that show you what's happening in real time. Some platforms give you a live dashboard where you can see failed transactions, reasons for failure, and where things got stuck, without digging through logs or waiting on IT.

Integration with modern TMS and WMS platforms enables comprehensive testing of complete business workflows. IoT sensors embedded into a shipment's packaging and linked to periodical EDI 214 messages would improve the visibility of shipment status in near real-time, creating new testing requirements for real-time data validation.

Testing capabilities across major EDI providers vary significantly. Cargoson offers API-first architecture that simplifies testing integration, while traditional providers like IBM Sterling focus on comprehensive validation tools for complex enterprise environments. Newer platforms emphasize automation and real-time validation, though enterprise-scale testing still requires careful platform evaluation.

Implementation Roadmap: From Testing Gaps to Production Success

30-Day Foundation Phase

Establish testing infrastructure and identify critical business scenarios. Map current testing gaps against the seven critical failure points. Implement basic automated validation tools and create realistic test data sets that reflect actual partner variations.

60-Day Validation Phase

Execute comprehensive testing across all identified scenarios. Validate integration points with production-like data volumes and test exception handling capabilities. Engage business users in workflow validation and document any discovered gaps.

90-Day Production Readiness Phase

Implement parallel testing with production systems and validate monitoring and alerting capabilities. Train operational teams on new testing procedures and establish ongoing validation processes for future changes.

Resource requirements typically include dedicated testing team members, specialized testing tools, and infrastructure to support production-like testing environments. ROI calculations should factor both direct cost savings from avoided errors and indirect benefits from improved partner relationships and operational efficiency.

Success metrics include error rates in production (target: under 1%), time to identify and resolve issues (target: under 4 hours), and partner satisfaction scores with transaction reliability.

Future-Proofing Your EDI Testing Strategy

API-EDI hybrid environments require testing strategies that validate both traditional EDI formats and modern API interfaces. AI and EDI, while initially unrelated, are two prominent technologies in today's business world. As we see artificial intelligence continuing to break into nearly every sector of business, there is no doubt artificial intelligence (AI) can and will be integrated with electronic data interchange (EDI) to enhance B2B processes.

Blockchain integration testing considerations emerge as supply chains explore distributed ledger technologies for transaction validation and audit trails. Testing frameworks must validate both traditional EDI processing and blockchain verification processes.

Quantum-resistant security testing becomes relevant as encryption standards evolve. Testing procedures need to validate that EDI systems can adapt to new security requirements without disrupting business operations.

Integration with emerging technologies like IoT sensors and real-time tracking requires testing frameworks that can handle continuous data streams rather than batch processing scenarios. Globally, the EDI (electronic data interchange) market is projected to reach $49.21 billion by 2027, driven partly by these expanded integration requirements.

The evolution toward comprehensive testing validation isn't optional—it's essential for maintaining operational reliability in increasingly complex supply chain environments. Companies that address testing gaps proactively avoid the substantial costs of production failures while building competitive advantages through operational excellence.