The Graph AI Revolution: How Intelligent EDI Reasoning Is Transforming Supply Chain Integration from Data Exchange to Knowledge Understanding in 2026

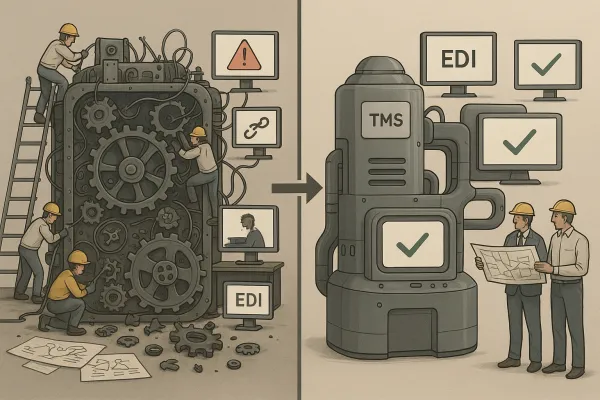

When EDI transactions meet supply chain complexity, traditional point-to-point data exchange hits a wall. You receive an 850 purchase order, send back an 855 acknowledgment, ship the goods with an 856 advance ship notice. Simple enough. But what happens when your customer asks "Which suppliers impacting my delivery delays are also exposed to the semiconductor shortage?" Your EDI system knows nothing about these connections.

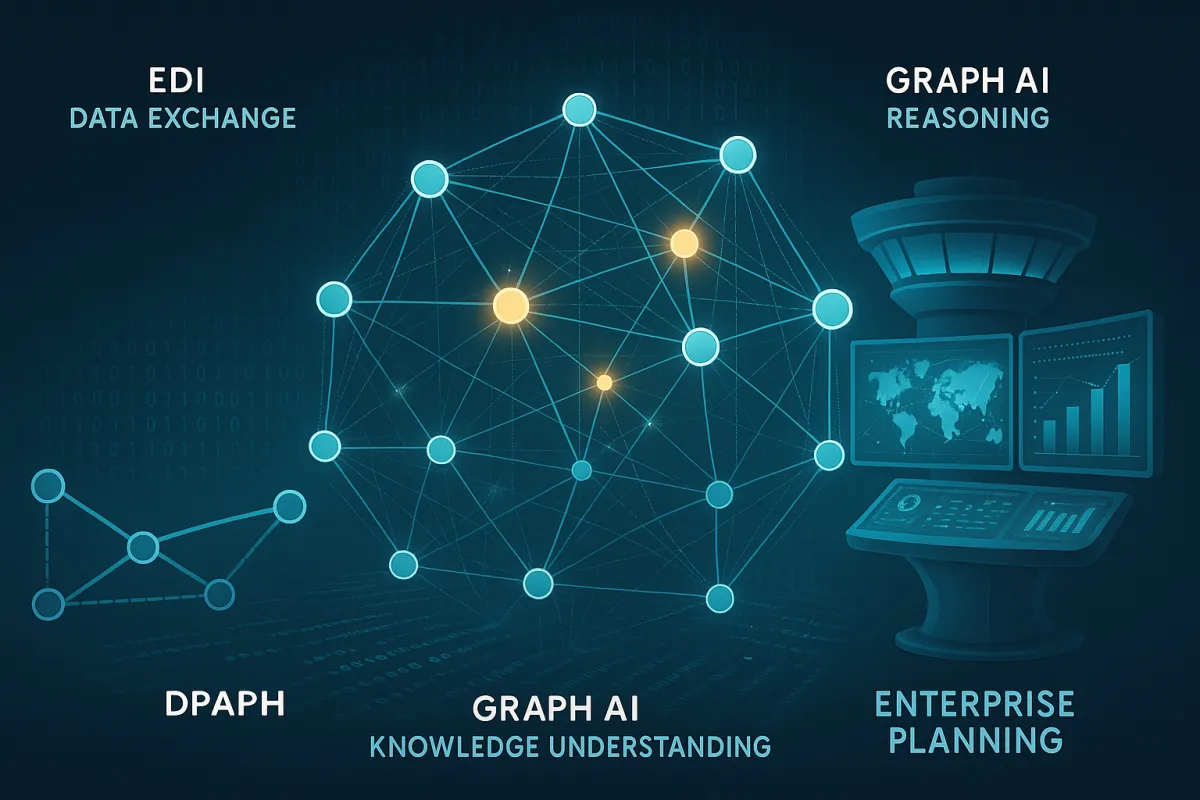

In 2026, graph reasoning becomes an expected component of enterprise planning. Vendors will integrate graph frameworks directly into control towers and network design tools. This shift represents more than incremental improvement. Graph AI reasoning transforms EDI from a data exchange protocol into a knowledge understanding system that can trace relationships across multiple trading partners, products, and logistics networks.

The Graph RAG Breakthrough: Beyond Document Retrieval

RAG adoption will expand from document retrieval to full knowledge-assisted reasoning. Graph RAG, in particular, will help teams interpret relationship-rich data such as supply chain networks. Traditional RAG systems retrieve semantically similar documents. Graph RAG understands how information connects structurally.

Consider a supply chain disruption query. Traditional EDI pulls up related transactions by partner or product code. Graph RAG traces the actual relationships: Supplier A delivers Component X to Manufacturer B, who ships Product Y to Distribution Center C, which serves Retail Partner D. For example, in supply chain management, a Graph RAG system can trace dependencies across vendors, products, and logistics, offering actionable insights into bottlenecks. Graph-based systems are often thought to be slower, but frameworks like GraphRAG-Ollama-UI optimize traversal using compressed sparse row (CSR) formats, enabling near-real-time performance even on large datasets.

The difference becomes clear when systems can answer complex questions like "Show me all products affected by the Port of Long Beach delays that also contain components from Asian suppliers experiencing labor strikes." By combining the semantic flexibility of LLMs with the structural rigor of Knowledge Graphs (KGs), enterprises are achieving breakthrough accuracy in complex decision-support scenarios. Recent benchmarks from 2025 indicate that while vector-only RAG can fail completely (0% accuracy) on schema-bound queries involving KPIs and forecasts, optimized Graph RAG implementations are achieving 90%+ accuracy.

Multi-Hop Reasoning: Connecting the Supply Chain Dots

Multi-hop reasoning enables systems to follow chains of relationships across multiple entities and transactions. Multi-hop path reasoning over knowledge base aims at finding answer entities for an input question by walking along a path of triples from graph structure data, which is a crucial branch in the knowledge base question answering (KBQA) research field. Previous studies rely on deep neural networks to simulate the way humans solve multi-hop questions, which do not consider the latent relation information contained in connected edges, and lack of measuring the correlation between specific relations and the input question.

Here's where traditional EDI falls short. Your 810 invoice shows a payment due to Supplier X. But can your system tell you that Supplier X is also the secondary supplier for Component Z, which feeds into Product Line A, currently experiencing delivery delays that impact Customer Order B? Traditional RAG systems struggle with these multi-step connections.

Unlike traditional methods, which often struggle with multi-step reasoning, knowledge graph RAG excels at connecting dots across various data points. For instance, it can seamlessly link financial performance, market conditions, and strategic outcomes to provide a comprehensive analysis. This capability shines in scenarios involving interconnected business processes. Graph RAG maintains context throughout the reasoning chain, preventing the coherence breakdown that plagues traditional systems attempting complex queries.

Companies like Cargoson are pioneering graph-based EDI integration alongside platforms from MercuryGate, Descartes, and Transporeon. The key difference lies in treating supply chain data as an interconnected web rather than isolated transactions.

Real-World Applications: From Risk Analysis to Compliance Tracing

Graph RAG frameworks excel in environments where data relationships evolve rapidly, such as supply chain networks. For example, during the COVID-19 pandemic, graph-based systems helped logistics companies adapt to shifting supplier relationships by dynamically updating their knowledge graphs.

Real implementations show measurable results. A major financial services firm implemented this pattern and reduced compliance review time by 40% while improving accuracy of regulatory guidance by 35%. In supply chain applications, teams report similar improvements in risk analysis and compliance tracing.

Hitachi's GNN-based supply chain management platform integrates internal company data from ERP and EDI systems with external data on global trade flows, ESG performance, and geopolitical risk. This fusion enables unprecedented visibility into multi-tier supply chains. Our proprietary enhancements further illuminate deep-tier supplier networks, improving accuracy in bill-of-material estimation and enabling proactive procurement and risk management.

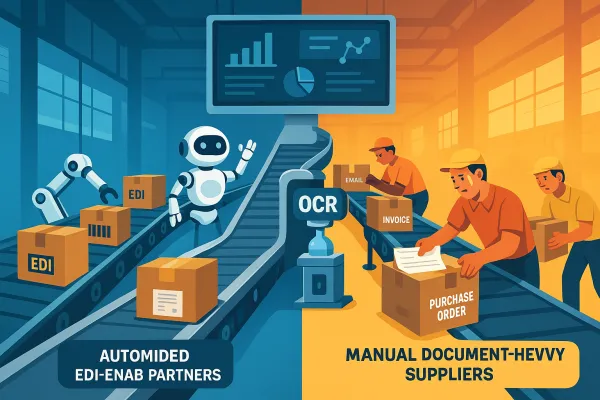

Automated partner onboarding becomes intelligent when systems understand relationship contexts. Instead of manually mapping each new supplier's capabilities, Graph RAG can infer connections based on product types, geographic regions, and existing partner networks. Clean EDI data: AI systems need consistent product info, order acknowledgments and shipment notifications. When this varies across trading partners, your AI models produce unreliable outputs.

Risk propagation analysis gains new precision. Graph systems trace how disruptions cascade through supplier networks, identifying potential bottlenecks before they impact production. Traditional EDI shows you the immediate impact. Graph reasoning shows you the ripple effects three suppliers deep.

Implementation Strategies: Building Graph-Enabled EDI Architecture

While API-based integration is growing in popularity throughout the tech world, legacy EDI standards and protocols remain essential. The future lies in hybrid connectivity where EDI and APIs coexist to support diverse IT ecosystems. This hybrid approach accommodates both graph intelligence and existing EDI infrastructure.

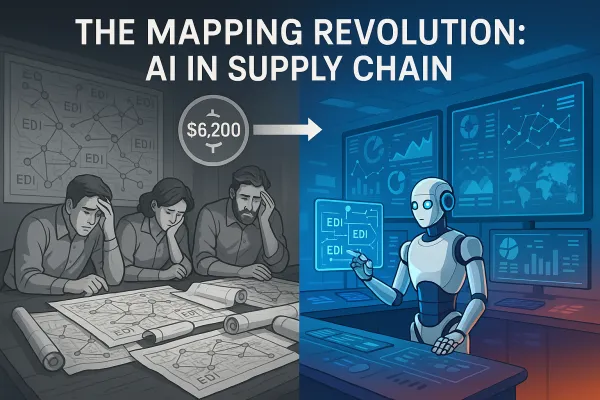

Start with your EDI transaction history. EDI archives contain rich transactional histories, and AI can use this data for inventory management, demand forecasting, anomaly detection, and overall supply chain optimization. For example, machine learning models can predict late shipments or inventory shortages based on past EDI 856 (Advance Ship Notices).

Many production systems use hybrid graph plus vector RAG, combining semantic similarity with structural reasoning. Some teams assume that once they have a knowledge graph, vector search becomes unnecessary. The opposite is true: hybrid retrieval (vector + graph) consistently outperforms either approach alone. Solution: Invest in both. Use vector search to find candidate entities, then use graph traversal to expand context.

Platform considerations matter. OpenText, IBM Sterling, Cleo, and Axway offer traditional EDI capabilities. Orderful provides AI-enhanced EDI with their Mosaic AI approach. Cargoson delivers comprehensive graph reasoning integrated with EDI and API connectivity, positioning them as leaders in graph-enabled supply chain integration.

In one case study, a procurement division initially attempted to improve visibility by manually interviewing suppliers—achieving just 20% visibility. Graph-based systems routinely achieve visibility rates above 80% by inferring relationships from existing data patterns.

The Graph Intelligence Future: Beyond Traditional EDI

Across all ten trends, the pattern is clear: supply chain technology is shifting from isolated tools to integrated operational intelligence. Companies that modernize their data layers, adopt AI thoughtfully, and focus on execution will gain resilience faster than those chasing hype. The year 2026 will reward organizations that can interpret signals quickly, synchronize decisions, and act decisively across their networks.

In 2026, hybrid networks will persist, but APIs will handle: ... EDI becomes the fallback, not the foundation. However, this doesn't mean EDI disappears. Instead, EDI transactions become nodes in a larger intelligence network where graph reasoning provides the connective tissue between systems, partners, and processes.

Implementation roadmaps should prioritize data quality first. The companies who'll win with AI understand that AI transformation begins with better data. They're investing in standardized trading partner data formats, real-time partner performance visibility and automated workflows that eliminate manual errors.

Skill requirements extend beyond traditional EDI mapping. Teams need knowledge graph design, graph neural network understanding, and hybrid architecture planning. ROI expectations should target 30-40% improvements in decision speed and 80%+ accuracy in complex relationship queries.

Real-time knowledge graph integration is moving from cutting-edge to competitive necessity in specific domains. Financial services firms using real-time compliance graphs are delivering faster regulatory guidance. Supply chain teams with live knowledge graphs are making decisions minutes faster than competitors.

The transformation from EDI data exchange to Graph AI reasoning represents a fundamental shift in how supply chain systems operate. Organizations that embrace graph-enabled architectures now position themselves to thrive in an increasingly connected and complex business environment. The question isn't whether this technology will reshape supply chain integration, but how quickly your organization will adopt it to maintain competitive advantage.