The Hidden $2.3 Million Opportunity in Your EDI Archives: How to Transform Dark Transaction Data Into Supply Chain Intelligence That Drives Strategic Decisions in 2025

Your EDI transaction archives are sitting on a goldmine worth $2.3 million annually for mid-size companies, according to recent analytics studies. Yet 55% of your organization's data remains "dark" - untapped, hidden, or unknown. Most supply chain professionals focus on processing today's transactions while ignoring the intelligence buried in years of historical EDI data.

Here's the reality: while approximately 20% of all supply chain data is structured and can be easily analyzed, 80% of supply chain data is unstructured or dark data. That's decades of purchase orders, advanced shipping notices, invoices, and carrier performance metrics collecting virtual dust in your archives.

The Supply Chain Dark Data Crisis - Why Your EDI Archives Remain Hidden Assets

Dark data is the collection of unprocessed information generated by fleets, freight systems, and supply chains. The data is collected by companies during regular business interactions, but the potential usually remains untapped. In EDI terms, this includes every 850 purchase order response time, every 856 shipment deviation pattern, and every 810 invoice exception that gets logged but never analyzed.

The statistics are sobering: estimates say that less than 1% of data is ever analyzed or used, with most companies only analyzing 1% of their data. Your EDI infrastructure processes millions of transactions annually, but you're missing patterns that could predict supplier disruptions, optimize carrier performance, and reduce procurement costs.

What Makes EDI Data "Dark" - Common Blind Spots in Supply Chain Analytics

Most EDI implementations focus on transaction throughput rather than analytical potential. Your AS2 connections process 856 ASNs flawlessly, but you're not tracking which suppliers consistently ship early or late. You receive 810 invoices without analyzing payment term optimization opportunities across trading partners.

According to Gartner, "dark data is the information assets organizations collect, process, and store during regular business activities, but generally fail to use for other purposes (for example, analytics, business relationships and direct monetizing). Similar to dark matter in physics, dark data often comprises most organizations' universe of information assets.

Legacy systems compound the problem. Your ERP might capture EDI transaction status, but it doesn't correlate seasonal demand patterns with supplier performance variations. That disconnect between operational systems and analytical capabilities keeps valuable insights hidden.

The Hidden Intelligence in Your EDI Transaction Archives

Your EDI archives contain rich transactional histories that reveal supply chain patterns invisible to real-time monitoring systems. AI and machine learning algorithms can analyze vast amounts of data generated through EDI transactions, identifying trends, anomalies, and opportunities for optimization.

Consider what's hiding in your historical 856 ASN data: seasonal shipping volume patterns, carrier performance variations by lane, and temperature-sensitive product handling metrics. A major retailer recently discovered 15% inventory cost reduction opportunities by analyzing three years of 846 inventory inquiry patterns.

EDI processes capture valuable data. Companies can analyze this data using predictive analytics or machine learning to make more accurate predictions about what customer demand will look like in the future. Your 850 purchase order archives contain demand forecasting gold - if you know how to mine it.

Real-World Examples of EDI Analytics Success Stories

A Fortune 500 manufacturer analyzed two years of 858/859 shipment data and discovered that specific carrier routes consistently exceeded promised delivery windows during Q4. By switching carriers for those lanes, they reduced holiday shipping costs by 23% and improved on-time delivery rates.

A leading retail corporation has reported a 30% increase in efficiency by adopting AI-driven EDI solutions, minimizing manual interventions and errors. Their success came from analyzing exception patterns in historical 855 purchase order acknowledgments to predict supplier capacity constraints.

Transportation companies are seeing similar gains. The data can be used to optimize routes, improve fleet management, and enhance supply chain visibility. Analyzing data from GPS trackers, telematics, and historical data is very useful for boosting delivery performance, routes, and fuel efficiency.

Building Your EDI Data Analytics Infrastructure - The Technical Implementation Guide

AI enhances EDI by automating data entry and conversion, improving data quality, automating exception handling, and optimizing supply chains. These advancements not only boost the efficiency and accuracy of EDI processes but also provide deeper insights and greater control over supply chain operations.

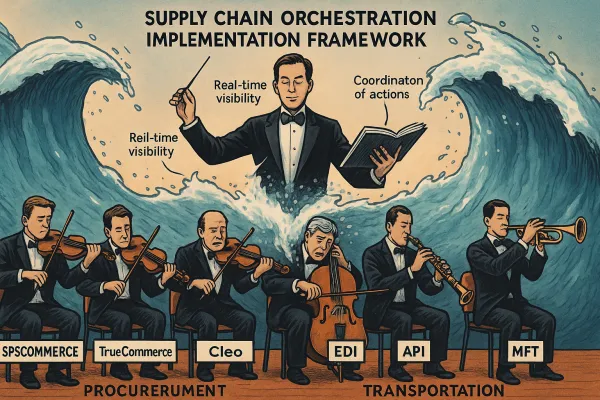

Start with data extraction from your EDI transaction logs. Most EDI platforms like IBM Sterling B2B Integrator, Cleo, and Cargoson maintain transaction archives, but accessing this data for analytics requires specific approaches. You'll need to establish data pipelines that can handle both structured transaction data and unstructured log files.

Modern analytics platforms like Tableau, Power BI, and Qlik can process EDI data, but they require proper data preparation. Additionally, integrating machine learning algorithms into EDI systems will enable predictive analytics, allowing businesses to anticipate customer needs and optimize supply chain management processes in real time.

Essential EDI Data Points for Supply Chain Analytics

Focus on transaction timing patterns first. Track the complete 850→855→856→810 cycle times by trading partner to identify bottlenecks. Monitor exception rates by transaction type - a sudden increase in 997 functional acknowledgment errors often predicts larger supply chain disruptions.

Carrier performance metrics buried in 856 ASN data provide another rich vein. Analyze pickup-to-delivery times, damage rates by handling facility, and seasonal performance variations. This intelligence drives better carrier negotiations and route optimization decisions.

Document compliance patterns across your supplier base. Partners who consistently send error-free EDI transactions often demonstrate stronger operational capabilities - valuable insight for supplier relationship management and risk assessment.

From Raw EDI Data to Actionable Business Intelligence - Analytics Frameworks That Work

AI's analytical capabilities allow businesses to gain deeper insights into their supply chain operations. By analyzing EDI data, AI can identify patterns and trends that highlight opportunities for optimization. For instance, AI can suggest ways to reduce inventory costs, improve delivery times, and enhance supplier relationships. These insights enable businesses to make data-driven decisions that optimize their supply chains for better performance.

Implement a three-tier analytics approach. Descriptive analytics reveal what happened - supplier performance trends, seasonal demand patterns, and cost variations. Predictive analytics forecast what might happen based on historical patterns. Prescriptive analytics recommend specific actions.

A mid-size distributor implemented this framework using their historical EDI data and discovered that certain suppliers had 40% higher defect rates during summer months. This insight led to proactive quality discussions and alternative sourcing strategies that reduced warranty claims by $180,000 annually.

Key Performance Indicators (KPIs) to Track

Monitor order-to-cash cycle times by trading partner and product category. Track supplier compliance rates across different transaction types. Measure freight cost per unit trends and identify optimization opportunities through mode shifting and carrier performance analysis.

Exception rates by trading partner reveal operational maturity levels. Partners with consistently low 997 functional acknowledgment error rates typically demonstrate stronger process controls and system reliability.

Overcoming Implementation Challenges - Practical Solutions for Common Obstacles

Failure to manage dark data is not just a lost business opportunity, but also a risk concern. Despite the growing recognition of data's value, many businesses are struggling to unlock its full potential. While artificial intelligence promises to drive innovation, only a small percentage of companies are currently using it effectively, largely due to the challenges of accessing and managing this dark data.

Legacy system integration poses the biggest challenge. Your EDI platform might use different data formats than your ERP or WMS systems. Solutions like Cargoson's TMS integration, alongside platforms from MercuryGate, nShift, and Oracle TM, can bridge these gaps by providing unified data access layers.

Staff training requires cross-functional collaboration. Your IT team understands EDI transaction structures, but your operations team knows what insights matter most. Create joint training programs that combine technical EDI knowledge with business analytics skills.

Change Management for Analytics-Driven EDI Operations

Building data-driven decision-making culture requires demonstrating quick wins. Start with simple analyses - like identifying your most reliable suppliers based on 855 acknowledgment timing - before moving to complex predictive models.

Vendor selection should consider analytics capabilities alongside traditional EDI functionality. Modern platforms from providers like TrueCommerce, SPS Commerce, and managed service providers offer built-in analytics tools that reduce implementation complexity.

Measuring Success - ROI Metrics and Performance Benchmarks for EDI Analytics Programs

Cost reduction measurements show immediate impact. Eliminate chargebacks, reduce revenue leakage by 30%, and cut research time by 50% with your customized EDI dashboard. Track inventory optimization savings, freight cost reductions through better carrier selection, and exception handling efficiency improvements.

Revenue enhancement comes from faster order processing and improved customer satisfaction. Operational analytics - Dark equipment sensor data and supply chain records could optimize performance when studied. Cost savings and quality gains slip away. Predictive modeling - Dark data applied to machine learning algorithms enables more accurate forecasting of business metrics and events. Those predictions can't materialize if data stays dark.

Long-term strategic benefits include competitive advantage through superior supply chain intelligence. Companies that effectively analyze their EDI dark data can predict market disruptions, optimize supplier relationships, and respond faster to demand changes than competitors relying only on real-time data.

Start small, think big. Begin with one trading partner or transaction type, demonstrate value, then expand across your entire EDI ecosystem. By bringing dark data into the light, businesses can discover new ways to optimize operations, reduce costs, increase sustainability, and stay ahead of the curve. Ignite the potential of dark data, and lead your organization toward a brighter, more informed future.

Your EDI archives aren't just compliance requirements - they're strategic assets waiting to transform your supply chain intelligence. The question isn't whether you have valuable data, but when you'll start using it to drive competitive advantage.