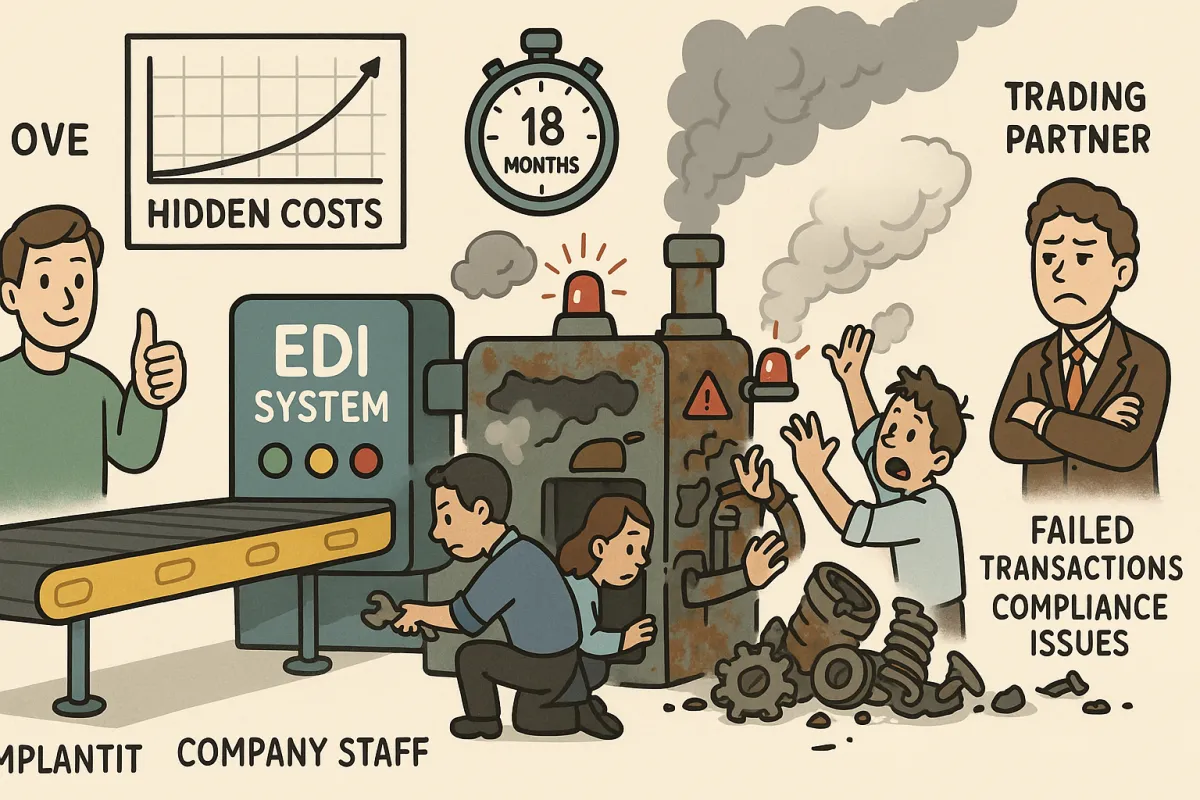

The Hidden $480K Post-Implementation EDI Maintenance Crisis: Your Complete Framework to Eliminate Ongoing Operational Burdens and Prevent the 73% Performance Degradation That Hits Most Systems 18 Months After Go-Live

Most EDI implementations successfully reach go-live status. The real problems start months later when systems quietly degrade, costs multiply, and trading partners begin complaining about failed transactions. Companies fail to regularly assess system performance after implementation, leading to undetected performance degradation, security vulnerabilities, and compliance issues that ripple across departments.

This isn't speculation. According to Gartner, 55 to 75 percent of ERP projects ultimately fail to meet their objectives, and EDI systems face similar challenges once the initial implementation excitement fades. Your project team disbands, documentation gets buried, and what seemed like a solved problem becomes an expensive burden requiring constant firefighting.

The financial impact can be staggering. Companies routinely underestimate ongoing EDI maintenance costs by 300-400%, turning projected savings into budget disasters. Hidden costs like fees for EDI VAN services, data mapping, ongoing maintenance and support of data translation can add up over time. This doesn't account for the compliance penalties, rushed fixes, and trading partner relationship damage that follows system degradation.

The Post-Go-Live Reality Gap That's Breaking EDI ROI Projections

A manufacturer spent six months and $200,000 implementing EDI with their largest trading partner. Launch day arrives, orders start flowing, and then everything breaks. Wrong product codes, incorrect pricing, and other errors begin to flood the system, shipping gets delayed, and the trading partner threatens penalties.

This scenario repeats across companies of every size. EDI maintenance costs spiral after implementation because organizations treat these systems as "set it and forget it" solutions rather than dynamic environments requiring ongoing attention. EDI software typically ranges from $300 to $3,000 per month, but that's just the baseline. Real costs include system monitoring, data quality maintenance, trading partner requirement updates, and compliance management.

The maintenance burden grows exponentially as transaction volumes increase and trading partners evolve their requirements. Among trading partners, EDI standards change all the time, creating somewhat of a moving target for brands, making it difficult for them to maintain compliance. What worked during testing fails in production when partners send unexpected data formats or implement new validation rules.

Why Traditional EDI Training Fails to Prepare Teams for Ongoing Operations

Most EDI implementations focus extensively on initial setup but provide minimal guidance for ongoing troubleshooting. Training covers ideal scenarios rather than the messy realities of production systems. Completing basic tests is often mistaken for being production-ready because teams focus on ideal scenarios rather than everyday complexities. EDI failures typically occur in untested edge cases, such as partners sending old EDI segments or UTF-8 characters that break XML parsers.

When problems arise months later, internal teams lack the expertise to diagnose root causes quickly. Issues that should take hours to resolve stretch into days or weeks while transactions pile up and partners threaten chargebacks. Implementation teams often disband after go-live, leaving systems without clear ownership for continuous monitoring.

The knowledge gap becomes critical when dealing with real-world scenarios that training never covered. How do you handle a partner sending 10,000 transactions with slightly malformed date fields? What happens when your ERP system updates and breaks existing EDI mappings? These situations require deep technical knowledge that most internal teams don't possess.

The Five Critical Post-Implementation EDI Maintenance Challenges

EDI systems degrade predictably across five key areas. Understanding these failure patterns helps you prevent them rather than react after damage occurs.

Challenge #1: Trading Partner Requirement Changes and Version Drift

EDI errors often arise from discrepancies between technical designs and actual workflows. The data that flows in may not be inclusive of the needs of the business downstream from the initial data flow. Partners continuously update their EDI specifications, add new validation rules, or change required fields without adequate notice.

A major retailer might announce they're requiring additional product attributes in purchase order acknowledgments, giving suppliers 30 days to comply. Organizations without proper change management processes scramble to update mappings, test changes, and deploy updates before facing compliance penalties. This reactive approach creates rushed implementations that often introduce new errors.

Version drift compounds the problem when different trading partners use different versions of the same EDI standard. Your system might support ANSI X12 4010 while newer partners require 5010 with additional segments. EDI is supposed to be a standard, but in reality, every trading partner has its own variations. A one-size-fits-all map doesn't cut it. Each partner may require slightly different document structures, values, and timing.

Challenge #2: TMS Migration Disruptions and System Dependencies

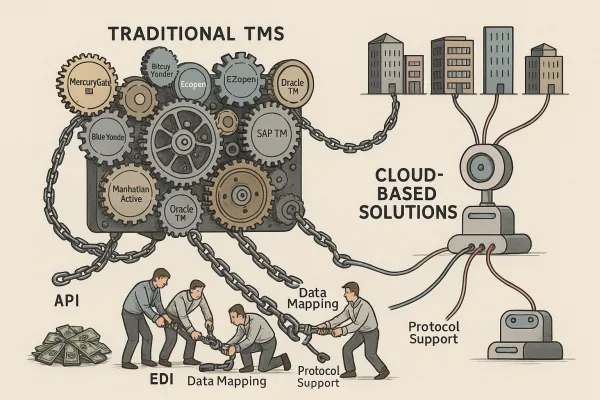

Transportation Management System migrations create particularly complex challenges for EDI operations. Legacy systems often use older protocols like FTP or AS2 that newer TMS platforms don't support natively. This forces organizations to maintain multiple communication paths or invest in protocol translation layers.

The tight coupling between EDI and TMS systems means any disruption in transportation management directly impacts EDI transaction processing. One of the biggest pitfalls in EDI implementations is data duplication between systems. Ideally, your ERP should be the single source of truth. However, most EDI solutions live outside of the ERP, forcing businesses to maintain data in two places.

When organizations migrate to cloud-based TMS platforms like those offered by MercuryGate or Blue Yonder, they often discover their EDI connections weren't designed for the transition. Transportation management systems like Cargoson address this through API-first architectures that maintain EDI compatibility while supporting modern integration approaches.

Challenge #3: Data Quality Degradation and Mapping Maintenance

Data quality problems originate at the order level and cascade through entire transaction flows. It all starts with the order, which is where many data-related issues occur. Bad data is both a business issue and an EDI issue. 16% of orders per month included an incorrect price, 20% involved out-of-stock or discontinued items, and 8% included a duplicate purchase order.

These errors trigger transaction failures that require manual intervention, defeating the automation purpose of EDI. Each manual fix consumes staff time and creates opportunities for additional errors. Organizations find themselves trapped in cycles where poor data quality generates more work rather than reducing it.

Mapping maintenance becomes increasingly complex as business rules evolve. What started as simple field translations grows into conditional logic handling dozens of partner-specific requirements. Without proper documentation and change control processes, these mappings become unmaintainable technical debt that breaks whenever underlying systems change.

Challenge #4: Security and Compliance Evolution

EDI systems handle vast amounts of confidential business data, requiring robust security protocols that must evolve with changing compliance requirements. Partners implement new encryption standards, regulatory bodies update data protection rules, and security vulnerabilities require immediate patches.

Ensure that your EDI provider complies with industry standards like ISO 27001 or PCI DSS for added protection. However, compliance isn't a one-time achievement. Organizations must continuously update security measures, monitor for vulnerabilities, and demonstrate ongoing compliance to auditors and trading partners.

The challenge intensifies when different partners require different security protocols. Some mandate AS2 with specific encryption algorithms, others require FTPS with particular certificate authorities, and newer partners may insist on API-based connections with OAuth authentication. Managing multiple security protocols while maintaining compliance across all connections demands specialized expertise.

Challenge #5: Performance Monitoring and Proactive Issue Resolution

Modern EDI platforms should provide real-time visibility into transaction processing, but many organizations lack the monitoring infrastructure to detect problems before they impact operations. The assessment includes analyzing factors such as message processing times, network latency, data throughput and system-response times. By examining these metrics, the health check will be able to spot bottlenecks, redundancies and other situations that may be slowing performance.

Without proactive monitoring, organizations discover problems only when trading partners complain about missing transactions or failed deliveries. This reactive approach damages relationships and often triggers penalty fees that far exceed the cost of proper monitoring tools.

Performance degradation happens gradually, making it difficult to detect without baseline measurements and trend analysis. Transaction processing times slowly increase, error rates creep upward, and system response times degrade until operational impacts become unavoidable.

The Complete Post-Implementation EDI Maintenance Framework

Successful EDI operations require systematic approaches to ongoing maintenance that go beyond basic technical support. Organizations need frameworks that address both technical and business aspects of EDI management.

Establishing Proactive Monitoring and Alert Systems

Effective monitoring starts with establishing baseline performance metrics during the initial implementation period. Metrics such as transaction accuracy, error rates, processing time, and cost savings can help monitor the system's performance and pinpoint areas for improvement. These baselines provide reference points for detecting performance degradation over time.

Modern monitoring systems should track multiple layers of EDI operations: network connectivity, message processing times, data validation results, and business rule compliance. Automated alerts notify teams immediately when thresholds are exceeded, preventing small issues from escalating into major problems.

Dashboard visibility allows stakeholders across different departments to understand EDI performance impacts on their operations. Finance teams need visibility into transaction volumes and compliance costs, while operations teams focus on processing times and error rates. Solutions from providers like Orderful, Cleo, and Cargoson offer comprehensive monitoring capabilities with role-based dashboards tailored to different user needs.

Trading Partner Lifecycle Management Strategy

Effective trading partner management requires structured approaches to onboarding, maintenance, and relationship optimization. Not all partners may have the same technical capacity for EDI integration, requiring flexible strategies that accommodate different capability levels.

Regular communication with key trading partners helps identify upcoming requirements changes before they become urgent implementation needs. Quarterly business reviews should include discussions about EDI performance, planned system updates, and emerging compliance requirements. This proactive engagement prevents last-minute scrambles to meet new partner requirements.

Partner testing protocols ensure changes don't break existing connections when implementing updates. Establishing dedicated testing environments and standardized validation procedures reduces the risk of production failures when deploying new mappings or communication protocols.

Cost Optimization and Resource Planning for Long-Term EDI Success

Long-term EDI success requires strategic planning that balances cost control with operational effectiveness. Organizations must make informed decisions about build vs. buy approaches while planning for future growth and changing requirements.

Building vs. Buying Ongoing EDI Support

To properly benefit from an EDI implementation, you need the support of experts to ensure that your EDI infrastructure continues to suit the needs of your organisation as it grows. Many businesses opt for EDI managed services rather than keeping all that expertise and responsibility in-house.

Managed service providers offer specialized expertise without the overhead of maintaining internal EDI teams. EDI experts will take on the responsibility of managing your EDI infrastructure and provide you with dedicated customer support. They will monitor your system for issues 24/7 and carry out routine maintenance to keep your EDI software operating effectively.

Cost comparison between managed services and internal teams reveals that specialized providers often deliver better value for organizations processing moderate transaction volumes. SPS Commerce and TrueCommerce offer comprehensive managed services with transparent pricing models, while Cargoson provides managed services specifically designed for transportation and logistics operations.

Organizations with high transaction volumes or unique requirements might benefit from hybrid approaches that combine internal expertise with external support for specialized functions like partner onboarding or compliance management.

Future-Proofing Your EDI Investment Through Strategic Planning

The EDI landscape continues evolving toward hybrid integration models that combine traditional EDI with modern API capabilities. These approaches provide backward compatibility with existing trading partners while enabling more efficient connections with newer systems.

EDI integration costs range from $8K–$25K per integration, plus 10–15% per year for API maintenance and break/fix. However, hybrid approaches can reduce long-term costs by standardizing integration patterns and reducing custom mapping requirements.

Strategic planning should consider how emerging technologies like blockchain, IoT sensors, and artificial intelligence will impact EDI operations. Transportation management systems are particularly well-positioned to benefit from these technologies, as they already handle complex data integration across multiple systems and partners.

Investment in flexible platforms that support both traditional EDI and modern API integration ensures organizations can adapt to changing partner requirements without replacing entire systems. This approach provides sustainable paths for modernization while protecting existing investments in EDI infrastructure.

Success in post-implementation EDI maintenance comes down to treating these systems as critical business infrastructure requiring ongoing investment and attention. Organizations that implement comprehensive maintenance frameworks, establish proactive monitoring, and plan strategically for evolution will maximize their EDI ROI while avoiding the common degradation patterns that plague many implementations after 18 months of operation.