The Hidden Batch Processing Tax: Why Legacy EDI Systems Are Costing Your Supply Chain 40% More Than You Think (And Your Step-by-Step Migration Roadmap)

Your EDI system is quietly burning through your budget faster than you realize. That morning batch run that processes orders from last night? The batch oriented nature of EDI means that you're getting data slowly, pulling FTP servers and processing batches of data. While you wait for those files to process, your competitors with real-time EDI are already shipping, billing, and moving on to the next opportunity.

Over 85% of global businesses have adopted B2B integration solutions to optimize their procurement and supply chain processes in 2024, but most are still stuck with legacy systems that create hidden costs worth 40% more than their actual subscription fees. This isn't just about technology—it's about money walking out your door every time a batch fails or a transaction gets delayed.

The Silent Cost Drain: How Batch Processing Creates Hidden EDI Expenses

The real EDI batch processing costs extend far beyond what appears on your monthly invoice. Hard EDI costs come in the form of compliance charges if your outbound documents aren't meeting your trading partners' requirements, often charged per document, and can add up quickly if the problem is systemic and the mapping process isn't corrected.

Here's what that actually looks like in dollars:

- Missed orders that get lost in 'the cloud', or invoices that are never delivered to your customers. Missed orders may not only mean that you miss out on that specific revenue, but can also aggressively sour your customer relationship, contributing to declining sales.

- Soft EDI costs result from problems that take employee time to identify, work around, and resolve, such as performing track-and-trace with your provider or VAN, manually matching functional acknowledgments, and manual steps involved in 'doing EDI' if your system isn't fully automated. These issues are tedious and time-consuming for employees, meaning that energy is misallocated.

- Hidden costs like fees for EDI VAN services, data mapping, ongoing maintenance and support of data translation, or compliance with industry standards. Some providers may charge additional fees for processing certain document types or for handling complex transactions that require special handling or validation.

The pattern repeats across industries. Many trading partners have strict EDI requirements for document formatting, processing times, and accuracy. An inefficient EDI solution may fail to meet these standards, leading to costly chargebacks and penalties. These non-compliance issues not only strain relationships with key partners, they can also diminish your profitability, especially when penalties accumulate over time.

Consider this: EDI solution providers calculate pricing by total number of KCs. 1 EDI document/transaction may or may not mean 1 KC, it could be multiple. So check with your EDI solution provider what is their record length of the characters to avoid any hidden costs. Most companies discover these details only after their first surprise invoice.

The Real-Time Revolution: Why 73% of Supply Chains Are Abandoning Batch EDI

New businesses are moving away from batch-based EDI toward real-time API-based EDI architectures. Traditional EDI uses batch processing and set communication windows, whereas API-integrated EDI lets systems send and receive data instantly and on demand, making them more responsive and flexible.

The market numbers tell the story: The electronic data interchange market is projected to exhibit a CAGR of 6.94% during 2025-2033, reaching a value of USD 75.30 billion by 2033. But here's what drives that growth—the rising demand for faster transaction processing and reduced paperwork, with integration of EDI with ERP and cloud-based platforms becoming common, offering scalability and real-time access.

The shift toward real-time EDI processing isn't just a technology upgrade—it's a business necessity. Real-time data exchange has become a standard feature, allowing businesses to make data-driven decisions quickly and respond to market demands. EDI solutions are becoming vital in achieving faster processing times, minimizing paperwork, and ensuring regulatory adherence. The growth of e-commerce and cross-border transactions is amplifying the need for real-time data sharing and secure document exchange.

Transportation management systems are leading this transition. Modern TMS platforms like MercuryGate, Descartes, Oracle, and Cargoson now offer native real-time EDI capabilities that eliminate the batch processing bottleneck entirely.

Case Study: Manufacturing Company Cuts EDI Costs by 60% Through Smart Automation

A mid-sized automotive parts manufacturer was processing 15,000 EDI transactions monthly through a batch system that ran three times daily. The delays created cascading problems:

- Order confirmations delayed by 8-12 hours

- Inventory discrepancies from stale data

- $45,000 monthly in chargeback penalties from slow acknowledgments

- 4 FTE staff members managing error resolution

After implementing real-time EDI automation integrated with their TMS, they achieved:

- Sub-5-minute transaction processing

- 92% reduction in chargebacks

- Reallocation of 3 FTE to revenue-generating activities

- Total monthly savings: $67,000

The implementation cost of $180,000 paid for itself in 2.7 months.

The Complete Cost-Benefit Analysis Framework for EDI Modernization

Before diving into EDI implementation costs, you need a systematic approach to calculate the true impact. Most CFOs miss the complete picture because they focus only on subscription fees while ignoring operational expenses.

Understanding the various components of EDI costs—from initial setup and EDI software prices to ongoing fees and potential hidden charges—will help you make the best decision. While managing an in-house EDI system requires an investment in infrastructure, software and dedicated personnel, partnering with an EDI provider can mitigate these upfront costs and complexities.

Start with this calculation framework:

Current State Analysis:

- Monthly transaction volume × average processing delay × hourly labor cost

- Annual chargeback penalties + compliance violation fees

- FTE hours spent on error resolution × fully loaded hourly rate

- Revenue lost from delayed order processing

Future State Projection:

- Real-time processing subscription costs

- Implementation and migration expenses

- Training and change management

- Expected efficiency gains in FTE utilization

The 8 Hidden Cost Categories Most CFOs Miss in EDI Budgets

Hidden costs can include unexpected trading partner fees, charges based on minimum data record lengths from providers, or indirect costs like the time employees spend resolving errors in inefficient systems. Here are the specific categories:

- VAN Network Fees: Check with your EDI solution provider what is their record length of the characters to avoid any hidden costs. If 1 EDI document/transaction accounts to 2 KC then you are paying the price for 2 KCs.

- Chargeback Penalties: Document formatting violations and timing compliance failures

- Error Resolution Labor: IT and operations staff time for troubleshooting failed batches

- Opportunity Cost: Revenue lost during processing delays

- Infrastructure Maintenance: Server resources, backup systems, monitoring tools

- Partner Onboarding: They have to wait for this onboarding process. That's been one of the key things that people have identified as a problem.

- Data Translation: Custom mapping for non-standard document formats

- Compliance Auditing: Regular reviews to meet changing regulations

Your 90-Day Migration Roadmap: From Batch Bottlenecks to Real-Time Results

The implementation process involves assessing current systems, selecting the right EDI solution, and conducting thorough testing. Businesses must address challenges such as technical complexity and data security concerns during integration.

Week 1-30: Assessment and Planning Phase

Before embarking on the integration process, businesses should evaluate their existing TMS and EDI systems. Understanding the current capabilities and limitations will help determine the best approach for integration. Assess what specific functionalities are required from the integration.

Key activities:

- Document current EDI transaction volumes and types

- Map existing trading partner requirements

- Identify integration points with ERP and TMS systems

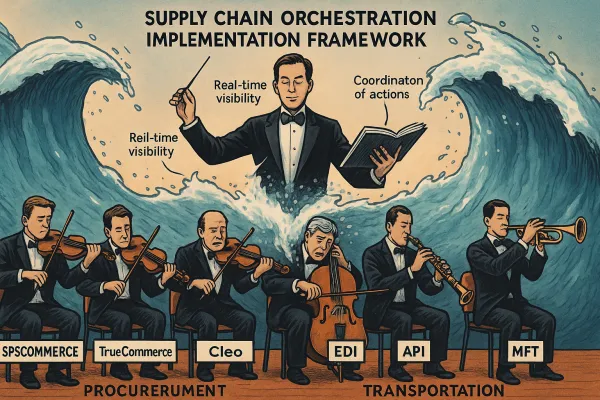

- Evaluate vendors: OpenText, Cleo, SPS Commerce, TrueCommerce, and emerging platforms like Cargoson

- Calculate total cost of ownership for each option

Week 31-60: Implementation and Testing

Integrating EDI with TMS can be technically challenging, especially for organizations with outdated systems or limited IT resources. Businesses may need to invest in middleware solutions to bridge the gap between legacy systems and modern EDI requirements. The initial investment for integration can be substantial, although it is often recouped through long-term savings.

Focus areas for this phase:

- Establishing how data will be mapped between the TMS and EDI systems is vital for seamless integration.

- Partner notification and testing coordination

- Parallel processing setup to maintain current operations

- Error handling and monitoring configuration

- Staff training on new processes

Week 61-90: Go-Live and Optimization

The final phase focuses on smooth transition and performance optimization:

- Gradual migration of trading partners to real-time processing

- Performance monitoring and threshold alerts

- Cost tracking to validate ROI projections

- Process refinement based on initial results

- Documentation of lessons learned

Avoiding the Top 5 Migration Mistakes That Increase Costs by 300%

For most shippers with annual freight under management greater than $250M, the implementation line item can be 2-3x the subscription. The "long pole of the tent" of implementation time, and therefore cost, resides in the design, build, and testing of integrations.

Here are the critical mistakes to avoid:

- Underestimating Integration Complexity: The quantity of integrations is the #1 driver of implementation duration and cost. Plan for 2-3x more integration work than initially estimated.

- Inadequate Partner Preparation: Make sure your trading partners are on board and their systems are compatible with your EDI setup. Work with partners to establish compatible versions or use translation software.

- Skipping Parallel Processing: Running old and new systems simultaneously during transition prevents data loss and maintains business continuity.

- Vendor Lock-in Risks: Once they've built up all their partners to get everything into the system, they're now locked in. They cannot move to anything else. So they're locked into that vendor's way of doing things and they don't have a lot of options moving forward.

- Poor Change Management: One of the things we hear a lot from customers is that they have one person in their organization who understands the EDI stuff, and if they lose that person, they're in big trouble. Try to encapsulate that knowledge somewhere so that you're not completely dependent on the only person who really understands the EDI environment.

Future-Proofing Your Investment: What's Next for EDI Automation

The EDI automation costs landscape is evolving rapidly. Artificial Intelligence is making EDI better by finding mistakes automatically, speeding up document mapping, and predicting problems in supply chain processes. EDI with AI and ML cut down on the need for human input, improve accuracy, and assist people make smart choices by using predictive analytics.

Integration of EDI with mobile technologies and analytics platforms is gaining momentum, providing real-time insights into transactional data and supply chain activities. Artificial intelligence and machine learning are beginning to play roles in enhancing error detection and correction during data exchange processes. Another notable trend is the increasing adoption of blockchain technology for secure and transparent EDI transactions.

The convergence of EDI and APIs represents the future. EDI is ideally suited for batch processing of mission-critical transactions like financial documents and periodic updates, APIs enable real-time data exchange for proactive decision-making to drive competitive advantage. Instead of completely throwing out one technology in exchange for another, integrating the best of EDI and API capabilities allows businesses to stay rooted in an industry-standard technology they know works while expanding its capabilities.

Transportation management platforms are already implementing this hybrid approach. Solutions from providers like Descartes, Manhattan Associates, BluJay Solutions, and Cargoson now offer seamless EDI-API integration that provides the reliability of traditional EDI with the speed of modern APIs.

Your batch processing system isn't just slow—it's expensive, risky, and increasingly obsolete. You're likely paying more than you need to and getting less in return. The question isn't whether to migrate to real-time EDI, but how quickly you can execute the transition while controlling costs and minimizing disruption.

Start your assessment now. Document your current costs, map your trading partner requirements, and calculate the true price of staying with batch processing. The companies moving to real-time EDI today will be the ones thriving tomorrow—while their competitors are still waiting for the morning batch to run.