The Multi-Modal EDI Integration Crisis: How to Build Unified Data Exchange Systems for IoT Sensors Across Road, Rail, Air, and Sea Transport Networks in 2025

After months of patchwork solutions and manual workarounds, the global EDI market's growth from US$ 30.64 billion in 2023 to a projected US$ 65.99 billion by 2031 doesn't feel like progress when your temperature sensors from three different transport modes speak entirely different languages.

Manufacturing supply chains face an unprecedented integration crisis. Multi-modal transportation optimization and port operations management are pushing IoT sensors deeper into logistics networks, but 53% of enterprises experience limitations with their current B2B integration solutions when onboarding trading partners, with approximately 40% requiring over 30 days to bring a new partner online. That German automotive parts manufacturer who spent €800,000 on a TMS implementation? They discovered their system couldn't handle carrier integrations across 12 countries—a problem that's becoming more common as multi-modal EDI integration becomes the norm, not the exception.

The Growing Data Standardization Crisis in Multi-Modal Transport

Road, rail, maritime, and air transport each evolved their own data formats and communication protocols. EDI (Electronic data interchange) had been dominating inter-organisational connections since 1960s, with Internet-based systems growing significantly since the late 1990s. But that legacy created silos.

Your refrigerated truck uses EDI 214 status messages while your rail partner requires EDIFACT IFTSTA formats. EDI 214 (Transportation Carrier Shipment Status Message) is an X12 transaction set that transportation carriers use to send shipment statuses, including time, date, location, route, identification numbers, and conveyance. Maritime containers transmit sensor data through proprietary APIs, and air freight temperature monitoring systems often require entirely different integration approaches.

The practical impact hits immediately. When Cargoson processes multi-modal shipments alongside competitors like Transporeon (rail-focused), nShift (parcel), and MercuryGate (enterprise TMS), data format differences create bottlenecks that can delay critical temperature-sensitive shipments by hours. USA Truck discovered their EDI tools couldn't scale when they expanded their carrier network from 200 to 500+ partners. Processing times increased from 2 minutes to 45 minutes for standard load tenders.

IoT Sensor Data Integration Challenges Across Transport Modes

The number of IIoT devices worldwide is expected to reach 41 billion by 2027, and temperature monitoring represents a massive portion of that growth. In a recent study by UPS, more than 30 per cent of deliveries in the $76 billion global pharmaceutical logistics delivery market are reaching their destination with some degree of damage or spoilage.

Here's the real problem: IoT-enabled EDI integration refers to the automated, secure, and standardized exchange of business documents—triggered, enriched, and validated using real-time data captured from your physical manufacturing assets (machines, sensors, inventory trackers, and more). But each transport mode generates sensor data in different formats, sampling frequencies, and communication protocols.

Temperature sensors in refrigerated trucks might sample every 30 seconds via cellular networks, while shipping container sensors conserve battery by transmitting hourly summaries via satellite. The device sends live temperature, humidity, and GPS data to the cloud through 5G/4G/2G, meaning you always know where your load is and how it's doing. Rail cars use fixed infrastructure for data transmission, creating yet another integration challenge.

Cold Chain Monitoring Data Complexity

Pharmaceutical cold chain requirements differ dramatically from food monitoring. Stringent regulations govern the transportation and storage of temperature-sensitive goods. Failure to comply can result in penalties, product recalls, and damage to a brand's reputation. Proper temperature monitoring ensures compliance with these regulations by providing an audit trail of temperature measurements at every stage of the cold chain.

Monnit Wireless Temperature Sensor's industry-leading up to 25-month NIST certification. The sensors are also certified for Europe's EN12830 cold chain traceability standard shows how compliance creates additional data format requirements. Pharmaceutical shipments need continuous monitoring with specific excursion reporting, while food transport might accept broader temperature ranges with less frequent validation.

When integrating with enterprise TMS solutions like Manhattan Active, Blue Yonder, or Cargoson, you're dealing with different data validation rules for each industry. GPS-based cold chain tracking combine location tracking with temperature monitoring, providing visibility into the real-time movement and condition of temperature-sensitive shipments. They are widely used in pharmaceuticals, food transportation, and beverage industries to maintain product safety and quality.

Building a Unified EDI Integration Architecture

While EDI establishes a connection between two EDI systems, API is a web-based protocol that enables different programs to communicate. With cloud-based solutions, API allows transportation management systems (TMS) to transmit data in less than a second. But your unified framework needs both.

Design your architecture with these core components:

- Data Transformation Layer: Data is automatically mapped to the required formats (ANSI X12, EDIFACT, etc.) using proven templates provided by your EDI VAN partner

- Real-time Processing Engine: IoT sensors generate instant signals for every key business event—inventory dips, machine faults, shipment departures, or incoming goods. EDI transactions (orders, invoices, ASNs) are auto-populated and dispatched the moment action is required

- Multi-protocol Gateway: Supporting EDI, APIs, and proprietary sensor protocols simultaneously

MercuryGate, Descartes, and Cargoson have evolved their platforms to handle these hybrid scenarios. Modern transport execution software addresses many of these challenges by providing unified platforms that handle EDI, API, and hybrid communication methods from a single interface. Solutions from providers like Cargoson, MercuryGate, and Descartes are evolving to support this unified approach.

Data Transformation and Mapping Strategies

Converting IoT sensor data into standardized EDI formats requires more than simple field mapping. As a bin of screws is used up, an IoT sensor counts inventory in real time. When count dips below a set level, an EDI 850 (Purchase Order) is auto-generated and sent to the supplier, all with no manual entry. But temperature data presents unique challenges.

Temperature excursion events need to trigger multiple EDI documents simultaneously: status updates (EDI 214), exception reports, and potentially emergency notifications. Real-time alerts can instantly warn you if the temperature has fluctuated below or above a predetermined threshold so you can respond in the moment to mitigate any potential damage and waste.

Your mapping strategy must account for different sensor manufacturers, communication protocols (Modbus, CAN, proprietary), and regulatory requirements across jurisdictions. It seamlessly integrates with most industrial equipment and sensors, offering out-of-the-box support for common machine protocols like Modbus, RS-232, and CAN. This, and its ability to easily connect to the cloud, makes it a versatile choice for various industrial applications.

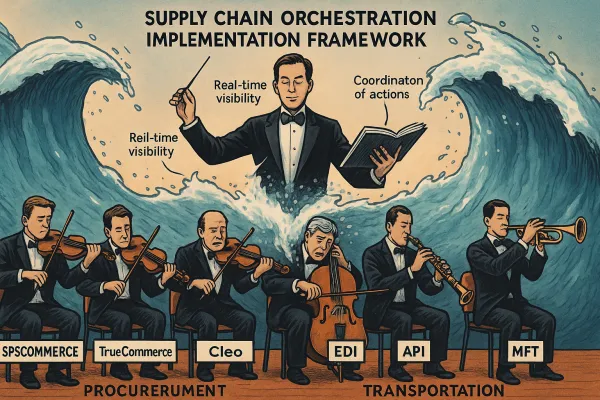

Implementation Framework and Best Practices

Start with your highest-volume, most critical lanes. Start with your most critical lanes, establish your hybrid framework, and build from there. Your competitive advantage lies not in picking the perfect integration standard, but in executing both reliably and efficiently.

Partner onboarding becomes crucial when roughly 25% of EDI connections have been replaced with APIs as of 2020. That said, legacy applications and technologies are still handling the majority of connections. Your framework needs to accommodate both scenarios without forcing partners to change their existing systems.

Testing protocols must validate sensor data accuracy across all transport modes. Run thorough tests before going live to ensure everything works smoothly. This includes temperature calibration verification, communication failover testing, and compliance validation for different regulatory environments.

Compliance and Regulatory Considerations

GDPR impacts sensor data collection and transmission across EU borders. The system should record and store temperature data over time, allowing for historical analysis and compliance documentation. The system should have configurable alarms and alerts to notify relevant personnel when temperature deviations occur.

FDA requirements for pharmaceutical shipments, customs documentation for international transport, and industry-specific standards like Good Distribution Practice (GDP) all create additional data format and retention requirements. Your unified framework must handle these automatically without manual intervention.

Technology Stack and Vendor Selection

Cloud-based solutions offer advantages for multi-modal integration, but while the internet is so commonplace, connectivity problems happen. API can be bogged down at the mercy of a stable internet connection due to interruptions that can affect every system connected via API. As anyone in the transportation industry will attest to, when it's down, nothing gets done.

When evaluating platforms like Oracle TM, SAP TM, 3Gtms/Pacejet, and Cargoson, consider their multi-modal capabilities specifically. Integrating both EDI and API in your TMS is like hitting the sweet spot for your trucking business. EDIs are your go-to for zipping through all those routine business papers, while API is the genius making sure your systems work together seamlessly.

A similar imperative exists in transport and logistics, where the integration of IoT data into Transport Management Systems (TMS) is indispensable. This trend is prevalent across all industries today, where true value materializes when IoT data becomes an integral part of industry-specific applications.

Cost-Benefit Analysis and ROI Calculations

European shippers managing €10 million+ annual transport spend are facing an unprecedented cost squeeze in 2025. The EU ETS now requires shipping firms to surrender 70% of 2025 emissions (up from 40%), with compliance costs rising significantly. Maersk expects emission surcharges in 2025 to be nearly double that of 2024.

Hidden costs include partner onboarding delays, data format conversion errors, and manual intervention requirements. By syncing machine data and scanning inputs directly to EDI, manual re-keying (and the risk of typos/omissions) is eradicated. This drastically reduces costly rework, chargebacks, and missed shipments from clerical errors.

Calculate ROI based on reduced processing times, error elimination, and improved compliance efficiency. Saves money: Automating stuff like entering data and handling documents means you spend less on the grind work. Bottom line? Merging EDI and API into your TMS isn't just about getting with the times. It's about building a digital powerhouse that takes your trucking business to the next level in efficiency, compliance, and customer satisfaction.

The multi-modal integration crisis isn't going away. This exploration revealed the imperative for advanced sensor technologies and integrated data management systems, capable of providing real-time, accurate temperature readings throughout the entire cold chain process. Your competitive advantage comes from building systems that work reliably across all transport modes while positioning for the inevitable shift toward more API-based integrations.

Start with your most critical lanes, establish clear data transformation protocols, and choose partners who understand both EDI legacy systems and modern API requirements. The companies succeeding in 2025 aren't picking sides—they're building frameworks flexible enough to handle whatever combination of transport modes and integration standards their business requires.