The Real-Time EDI Implementation Roadmap: How to Eliminate Batch Processing Delays and Unlock Instant Supply Chain Visibility Without Breaking Trading Partner Networks in 2025

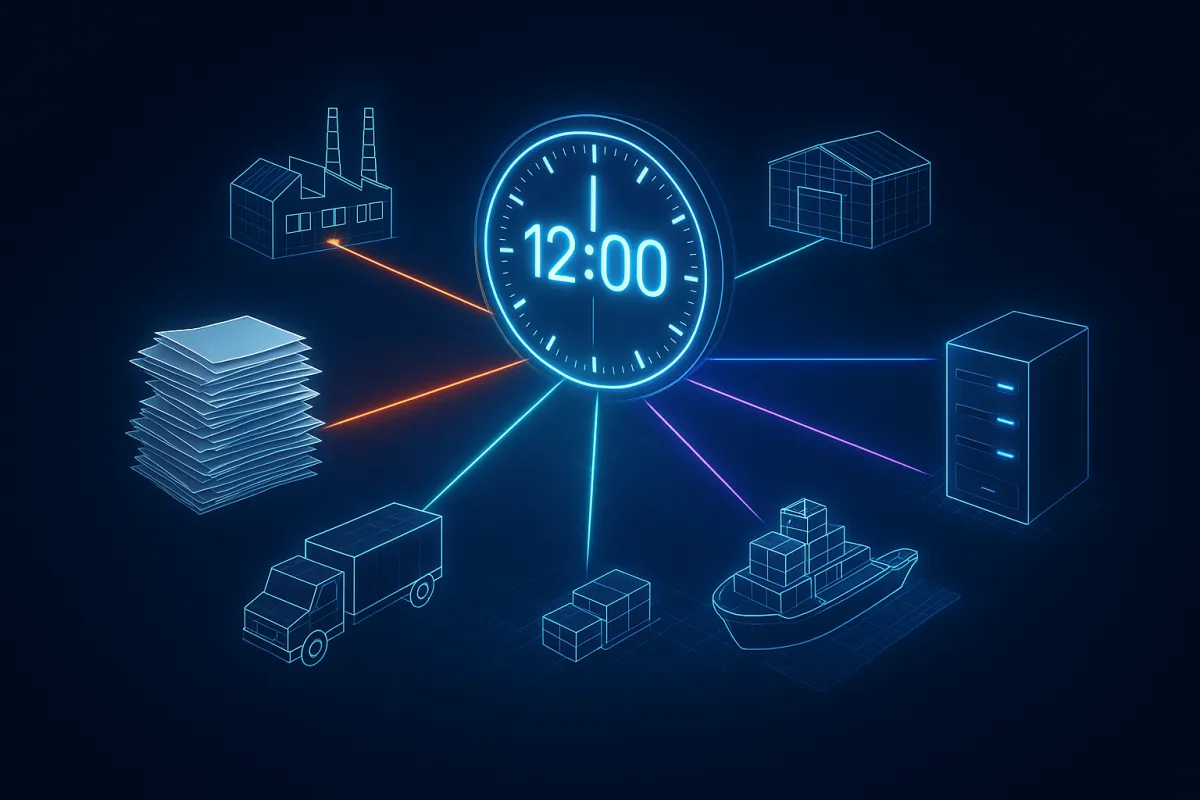

Supply chain visibility demands real-time data, not yesterday's batch reports. Traditional EDI systems often relied on batch processing, which could delay critical business decisions. In 2025, modern EDI platforms have shifted toward (near) real-time EDI with optimized data streams. Yet most companies remain trapped in outdated EDI workflows that process critical shipment updates hours after they occur.

The financial impact is measurable. Your customer portal shows actual dock departure, not yesterday's batch ASN time stamp. When your ASN arrives 8 hours after the truck departed, your customers see phantom inventory and make poor stocking decisions. The fix? A phased approach to real-time EDI that preserves trading partner relationships while unlocking instant supply chain visibility.

The Hidden Cost of Batch EDI Processing in Modern Supply Chains

Batch processing delays cost more than you think. Every delayed 856 Advanced Ship Notice means your customers can't accurately track inbound inventory. Without automation, businesses struggle with delayed data exchanges between carriers, suppliers, and warehouses. When carrier status updates take 4-6 hours to appear in your TMS, planners miss critical re-routing opportunities.

Transport management platforms like Cargoson alongside MercuryGate and Descartes solve this by processing EDI 214 status messages in real-time. When a carrier misses a cut-off, the TMS can instantly re-issue the load without a planner's phone call. Compare this to traditional EDI providers like IBM Sterling, where batch processing can delay status updates by hours.

Why Legacy Batch Systems Are Breaking Under 2025 Supply Chain Demands

Batch-based data processing creates visibility gaps that modern supply chains can't afford. Businesses without EDI-TMS integration experience poor visibility into shipments, leading to inefficiencies in tracking and route optimization. The competitive disadvantage multiplies when your rivals access real-time freight tracking while you wait for scheduled batch transmissions.

Consider dock congestion. Without live door scheduling data, carriers arrive unpredictably and create expensive delays. Modern solutions like Orderful's Mosaic provide real-time visibility into transactions, while legacy batch systems process appointment data once or twice daily.

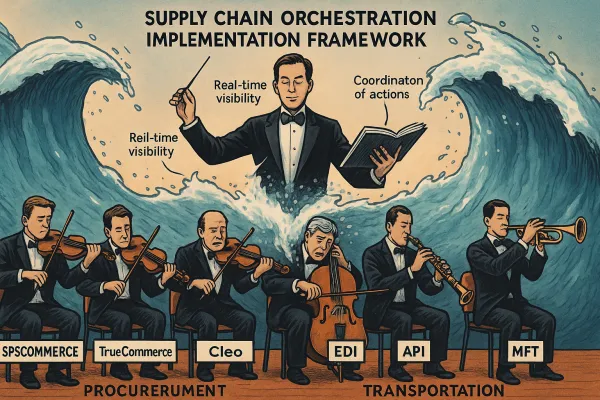

The Strategic Framework for Phased Real-Time EDI Migration

Real-time EDI transformation requires a risk-managed approach based on three readiness factors. Partner Readiness, System Limits - your WMS, TMS, or ERP can send and receive API messages without messy workarounds. Compliance Comfort - finance and quality teams are confident using digital logs in place of traditional EDI control reports. Until all three align, a compromise is necessary.

Cost breakdowns vary significantly by scope. Single-lane pilots begin around $50,000 and often focus on high-value routes or problematic trading partners. Global rollouts range from $200,000 to $500,000, depending on partner complexity and integration requirements. Most EDI tools are priced on "per month" basis, and their entry-level pricing plan ranges from $24 to $248+ per month.

TMS platforms handle the integration differently. Manhattan Active and Blue Yonder offer native real-time capabilities, while solutions like Cargoson focus specifically on transportation workflows. The key is matching your platform capabilities to transformation timeline.

Phase 1: Dock Scheduling as Your Real-Time Proving Ground

Start with dock scheduling because it solves daily operational pain while creating a safe testing environment for APIs. Dock scheduling software gives you live dock intelligence that EDI never could. Door congestion costs money immediately, making ROI calculations straightforward.

Implementation typically takes 6-8 weeks and pays back within a year through faster gate turns and fewer detention charges. Your team gains API experience without risking core business documents. Success here builds confidence for broader real-time initiatives across purchase orders and inventory updates.

Hybrid EDI-API Architecture: The Practical Implementation Model

Most successful transformations run both systems simultaneously during transition. Plenty of shippers use both EDI and API. The simple approach is just to split workloads. Live, decision-driving data travels via API while audit-critical records that make more sense in a document anyway stay on EDI.

Document-by-document migration works best. Moving status-heavy documents (163, 214, appointment notes) to API is optional and partner-by-partner. Inventory-centric documents (943, 856, 945, 846) keep riding EDI until your ERP and trading partners are ready for a broader API leap. This preserves audit compliance while gaining operational speed where it matters most.

TMS integration capabilities vary significantly. Oracle TM and SAP TM offer comprehensive hybrid approaches, while specialized solutions like Cargoson optimize specifically for transportation workflows. ERP, WMS, CRM, ELDs, Carrier, and BI platforms are the multiple means of integration including EDI and real-time APIs.

Gateway Solutions for Gradual Partner Migration

Middleware gateways solve the partner readiness challenge. This cloud service takes in an API call and quietly converts it to X12 or EDIFACT (and back again) so every partner sees its preferred format. You gain real‑time speed without asking every carrier or supplier to re‑tool at once, though you do pay a translation fee for the convenience.

Gateway pricing typically adds 15-25% to integration costs, but enables faster rollouts. Partners continue using existing EDI connections while you gain API speed internally. This approach works particularly well for transportation management where carrier systems vary widely in sophistication.

Real-Time Exception Handling: Transforming Supply Chain Responsiveness

Real-time processing transforms supply chain exception handling from reactive to proactive. When shipments deviate from planned routes, instant alerts enable immediate corrective action. Visibility integration enables real-time alerts when shipments deviate from planned routes or schedules. Teams can act immediately, minimizing downstream disruptions.

Automatic updates flow to partners and customers throughout the shipping process. Instead of waiting for batch transmissions, customers receive immediate notification of delays, route changes, or delivery updates. With live tracking embedded in the TMS dashboard, customer service teams can provide instant updates to clients without relying on carriers for information. Retailers, in particular, benefit from increased trust and transparency.

Freight management leaders like Transporeon and E2open leverage this capability, while platforms like Cargoson focus specifically on transportation execution workflows. The operational impact includes reduced customer complaints, fewer emergency expedites, and improved on-time performance metrics.

Technology Vendor Selection Criteria for Real-Time EDI Success

Evaluate vendors on real-time transmission capabilities first. This powerful combination ensures real-time data exchange, eliminates manual errors, enhances data accuracy, improves transaction speeds, and optimizes transportation logistics. System integration matters equally - EDI tools should connect seamlessly with ERP, accounting, WMS, or TMS systems without complex custom development.

Cloud versus on-premise considerations have shifted dramatically. In 2025, the landscape has transformed with the rise of cloud-native and hybrid EDI platforms, making the technology more accessible, scalable, and cost-effective. Cloud-based EDI solutions reduce the need for on-site servers, enabling faster deployment and lower maintenance costs.

Compare established players like IBM Sterling and OpenText against emerging solutions. In the TMS-specific category, evaluate Cargoson alongside nShift and 3Gtms based on transportation workflow optimization, not just document processing capability.

ROI Measurement Framework for Real-Time EDI Investments

Build business cases around measurable operational improvements. Projects often pay back within 12 months through faster gate turns, reduced chargebacks, and eliminated manual data entry. Manual status checks, emails, and calls are drastically reduced. Automated updates and analytics from supply chain visibility platforms streamline workflow, cutting administrative overhead.

Cost-benefit analysis should include both hard savings (reduced labor, fewer errors) and soft benefits (improved customer satisfaction, faster decision-making). Consider the total cost of ownership over time. This includes factors such as implementation costs, training expenses, ongoing maintenance and support fees, and any potential costs associated with upgrading or scaling the solution as your business grows.

Compliance and audit considerations remain critical during transformation. Real-time systems must maintain the same audit trails and regulatory compliance as traditional EDI. Document digital logs alongside transaction records to satisfy finance and quality teams throughout the migration process.

2025 Implementation Timeline and Success Factors

Start with a 90-day pilot focused on one high-value lane or problematic trading partner. This limited scope allows testing without operational risk while building internal expertise. Expand gradually based on lessons learned and partner readiness assessment.

Change management drives success more than technology selection. Make sure your teams are confident with the new processes. Provide clear documentation and training, and establish a responsive support structure. Train operational staff on new real-time dashboards and exception handling procedures before launching each phase.

Monitor performance closely during transition periods. Monitor performance closely during the transition—and be ready to catch small issues before they escalate. Establish rollback procedures for each integration point to minimize business disruption if issues arise.

Stakeholder alignment accelerates adoption. Include finance teams in compliance discussions, operations teams in workflow design, and IT teams in integration planning. Success requires coordination across departments, not just technical implementation. The most successful transformations treat real-time EDI as a business process improvement, not a technology upgrade.