The TMS Migration Survival Guide: How to Build Future-Proof EDI Architecture That Survives System Changes and Protects Trading Partner Revenue in 2026

Your TMS vendor just announced a platform migration scheduled for Q2. Your current EDI system handles 400+ transaction maps for 120 trading partners. Moving to the new platform means re-onboarding every single partner, re-mapping every transaction set, and potentially losing partnerships if the migration fails.

Sound familiar? EDI performance bottlenecks cost companies an average of $62,000 per day in delayed shipments and processing errors. When transportation management systems are upgraded or replaced, EDI connections often break without warning. EDI and TMS systems are tightly intertwined—everything from tendering a load to confirming delivery relies on structured, automated data flows. When systems are swapped out without an EDI continuity plan, the result is often delays, chargebacks, or failed deliveries.

The Hidden $2.5 Million Risk of TMS-Dependent EDI Systems

Here's the uncomfortable truth: 47% of IT managers say that slow EDI supplier onboarding is currently keeping their businesses from capturing new revenue opportunities. Nearly a quarter of companies (24%) are losing $500K or more to integration issues related to their supply chains. When you factor in the complete re-onboarding nightmare that follows a TMS migration, those losses multiply fast.

Take a mid-size manufacturer with 150 trading partners. Approximately 40% of enterprises require over 30 days to onboard a new trading partner. Research by Ovum shows that 53% of enterprises experience limitations with their current B2B integration solutions when onboarding trading partners, with approximately 40% requiring over 30 days to bring a new partner online. During a TMS migration, you're essentially re-onboarding every single partner. That's 150 partners × 40 days average × lost daily revenue. For many companies, that calculation easily hits $2.5 million in delayed or lost business.

The real kicker? Suppliers are losing approximately $27K in yearly revenue per trading partner and paying 35% more in EDI costs by dealing with multiple EDI vendors. Because of any/all of these factors, the suppliers are losing approximately $27K in yearly revenue per trading partner and paying 35% more in EDI costs by dealing with multiple EDI vendors. Now multiply that across a full system migration where partnerships fail during the transition.

Why Traditional TMS-Embedded EDI Creates Vendor Lock-in

The first challenge of EDI inside an ERP, TMS, or WMS is that it will be tightly tied to the ERP. When an enterprise grows and is looking to implement a new ERP or TMS, the switch will impact EDI with its trading partners. This creates a dangerous dependency that most IT directors don't fully appreciate until they're forced to migrate.

The problem runs deeper than surface-level integration issues. ERPs built into an EDI may cause consequences down the road, such as EDI downtime during an ERP outage or ERP migration. ERP, TMS, and WMS tend to have very lightweight EDI processing. Companies need additional communication software to support various protocols, custom scripts for EDI processing, database lookups, and complex integration between different systems.

Modern TMS solutions like Cargoson, nShift, and Transporeon offer robust transportation management capabilities, but when your EDI is locked into any single platform, you lose negotiation power and flexibility. What happens when your current vendor increases prices by 40%? Or when a competitor offers breakthrough AI-powered features that could transform your operations?

The Re-onboarding Crisis That Destroys Partnerships

Every TMS migration forces you to have "the conversation" with trading partners. You know the one: "We're upgrading our systems and need to re-establish our EDI connections." Nearly two-thirds (63%) of IT decision-makers say the EDI onboarding process takes too long because of all the different customized requirements demanded by trading partners. Up to 47% of IT managers say that slow EDI supplier onboarding is currently keeping their businesses from capturing new revenue opportunities.

Here's what typically happens: Your biggest customers grudgingly agree to re-onboard, but they're not happy about the disruption. Mid-tier partners start evaluating alternatives—why stick with a supplier who creates integration headaches? Smaller partners might lack the resources to handle yet another systems change, so they quietly shift their business elsewhere.

Most EDI implementations today take months rather than days. Your suppliers wait four to six weeks just to get onboarded with traditional EDI vendors, and in practice, the theoretical 1-2 week timeline often stretches to 1-2 months or longer. During a mass re-onboarding following a TMS migration, these timelines stretch even further as everyone competes for limited implementation resources.

Building Your TMS-Independent EDI Strategy

Smart supply chain professionals treat EDI as what it actually is: Standalone EDI systems are critical business applications that most organizations treat as tier 1 applications, since more than half of their business revenue goes through this platform. Companies want 100% uptime, even when performing upgrades to their ERP or TMS systems.

The key is architectural separation. Your EDI platform should integrate with your TMS through clean APIs or middleware, not be embedded within it. Separation of ERP is key as companies can avoid customizing their ERPs to handle EDI, which is costly and complex. Standalone EDI engines are also helpful when enterprises grow and have to switch to a new ERP. The same principle applies to TMS systems.

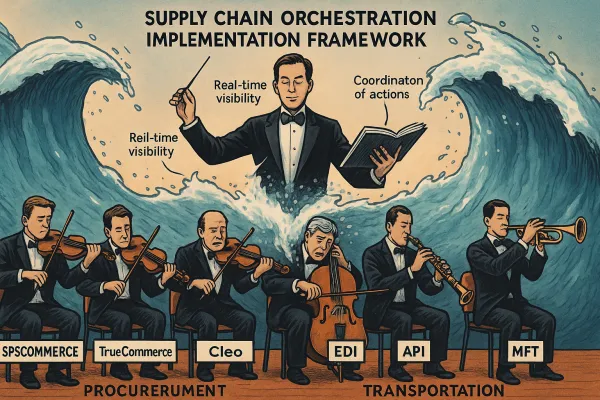

Consider this architecture: A standalone EDI hub (like those offered by Cleo, TrueCommerce, SPS Commerce, or OpenText) handles all partner communications and data transformations. Your TMS—whether it's Cargoson, Manhattan Active, Blue Yonder, or any other solution—connects to the EDI hub through standardized integration points. When you need to switch TMS vendors, you change one integration instead of re-onboarding 200 partners.

The Hybrid API-EDI Bridge Architecture

When Tesla chose to skip EDI in favor of API-based integrations, many carriers found themselves in a bind. Kleinschmidt stepped up to the plate, creating a repeatable process for their customers to transform carriers' existing data into API-compatible formats, making onboarding quick and painless. When Tesla chose to skip EDI in favor of API-based integrations, many carriers found themselves in a bind. Kleinschmidt stepped up to the plate, creating a repeatable process for their customers to transform carriers' existing data into API-compatible formats, making onboarding quick and painless.

This points to the future: hybrid architectures that support both EDI for traditional partners and APIs for digital-first customers. Your standalone EDI platform serves as the translation layer, converting between legacy EDI formats and modern API calls as needed. Whether it's EDI, API, or hybrid systems, this partnership makes compliance effortless. Digital integrations reduce manual data entry, saving time and minimizing costly mistakes. From tenders to status updates, your operations flow smoothly with fewer bottlenecks bringing data directly into your TMS.

The technical implementation involves placing an integration layer between your EDI platform and TMS that can handle format translations, routing rules, and error handling. Modern integration platforms offer pre-built connectors for major TMS solutions, making this approach more feasible than custom-coding everything from scratch.

The 90-Day Implementation Roadmap

Phase 1 (Days 1-30): Current State Assessment

Audit your existing EDI landscape. Document every trading partner connection, map type, communication protocol, and data transformation rule. Calculate the true cost of your current TMS-dependent setup by factoring in migration risks, vendor lock-in costs, and partnership vulnerability.

Phase 2 (Days 31-60): Data Mapping and Partner Analysis

Identify your top 20% of partners by revenue—these require white-glove migration treatment. Establish a tiered onboarding process: Tier 1 for simple, standard connections (target: 5 days), Tier 2 for moderate customization (15 days), and Tier 3 for complex, multi-system integrations (45 days maximum). Begin defining your data mapping standards early, as this becomes the foundation for your independent architecture.

Phase 3 (Days 61-75): Standalone EDI Deployment

Deploy your standalone EDI platform in a staging environment. Solutions like nShift, Transporeon, and Cargoson offer pre-built connectors to major shipping carriers, reducing onboarding time from weeks to hours for common logistics partners. Test connections with 2-3 low-risk partners first to validate your architecture.

Phase 4 (Days 76-90): TMS Integration Without Dependency

Connect your TMS to the EDI platform through the integration layer you've designed. Run parallel operations for at least two weeks, comparing transaction accuracy and performance between the old and new systems. This phase validates that your TMS can be swapped out without affecting partner relationships.

Managing the Transition: Zero-Downtime Migration Strategy

The secret to successful migration is never putting all your eggs in one basket at once. Run your new standalone EDI system alongside your existing setup, gradually moving partners over in small batches. This approach lets you catch and fix issues before they impact critical relationships.

Start with partners who have standard EDI requirements and strong technical teams. Partner onboarding accelerates dramatically: Consolidation reduces new trading partner setup from months to just 5 days, unlocking previously blocked revenue opportunities. This efficiency directly impacts revenue, as 47% of IT managers identified slow EDI supplier onboarding as blocking new revenue opportunities. Success with these early adopters builds confidence for more complex migrations.

Communication is critical. Give trading partners 60-90 days notice before any changes, provide clear migration timelines, and offer dedicated support during the transition. Most partners appreciate proactive communication about system improvements, especially when you can demonstrate faster processing and better reliability.

Your rollback procedures should be automatic, not manual. If a partner migration fails, you need to restore the old connection within minutes, not hours. Implement hybrid systems that allow legacy and modern EDI platforms to run in parallel during the transition. This approach minimizes operational disruptions and provides a safety net for addressing unexpected issues without halting critical financial processes.

Future-Proofing Your Architecture for 2026 and Beyond

The transportation industry is moving toward API-first architectures, but EDI isn't disappearing. In 2019, EDI amassed $7 trillion in B2B electronic sales. By 2021, this number rose to $8.38 trillion, as well as accounted for 76.5% of all digital sales. Furthermore, EDI grew year-over-year by 8.3% in 2021. Smart supply chain leaders are building hybrid architectures that support both.

Your TMS-agnostic EDI strategy positions you to take advantage of emerging technologies without massive disruption. Whether it's AI-powered data mapping, blockchain-based transaction verification, or real-time IoT integration, you can evaluate and adopt new capabilities based on business value, not vendor lock-in constraints.

Think about this: When the next breakthrough TMS solution emerges (and it will), you'll be able to evaluate it purely on its merits. Can it optimize your routes 15% better? Does it offer superior customer experience features? How about real-time analytics capabilities? With TMS-agnostic EDI, these decisions become business decisions, not technical migration projects.

The companies that thrive in 2026 will be those that built adaptable architectures in 2025. Whoever can most quickly adapt to each communication and data requirement - whether it's EDI, non-EDI, or API - will separate themselves and earn new business. TMS vendors will come and go, but your trading partner relationships and the data flows that power them need to remain rock-solid.

Start planning your TMS-agnostic EDI architecture today. Your trading partners—and your CFO—will thank you when the next "mandatory" system migration arrives and you can handle it without skipping a beat.