The TMS Vendor Selection Crisis: Your Complete Framework to Evaluate Hybrid EDI-API Integration Capabilities and Prevent the 73% Implementation Failure Rate in 2026

A German automotive parts manufacturer just spent €800,000 on a TMS implementation mistake. They chose a North American platform without realizing their European carriers couldn't integrate without costly custom development. Six months into deployment, they found their European carriers couldn't integrate without costly custom development work.

This isn't an isolated incident. 66% of technology projects end in partial or total failure, and 73% of discrete manufacturing ERP projects fail to meet their objectives, with average cost overruns reaching 215%. TMS procurement teams face similar challenges when they overlook a fundamental reality: roughly 25% of EDI connections have been replaced with APIs as of 2020. That said, legacy applications and technologies are still handling the majority of connections. Often playing the role of the intermediary, freight brokers will stand a far better chance if their TMS systems utilize both API and EDI integrations.

The Hidden Integration Crisis Forcing TMS Procurement Decisions

The most significant TMS vendor consolidation wave in over a decade is reshaping European procurement decisions right now. WiseTech's acquisition of E2open in 2025, Descartes' purchase of 3GTMS for $115 million in March 2025, and Körber's transformation of MercuryGate into Infios following their 2024 acquisition represent more than market shifts. They signal the end of the traditional TMS vendor selection playbook.

Integration timelines are extending as merged vendors focus on internal platform consolidation rather than customer-specific connectivity projects. This directly impacts European shippers whose carrier networks span multiple countries with varying technological capabilities. The European TMS market, valued at €1.4 billion in 2024 and growing at a compound annual growth rate of 12.2 percent, faces unprecedented complexity as buyers navigate hybrid EDI-API integration requirements while vendor options shrink.

Your TMS vendor selection criteria need immediate updates. Licensed TMS software runs $50,000-$400,000+ with annual maintenance charges ranging from 15-20% of license costs. For a 100-truck operation, that initial $100,000 investment becomes $200,000+ in the first year when you factor in implementation, training, and infrastructure requirements.

The Hybrid Integration Reality Check

Here's what most procurement teams miss: When Tesla chose to skip EDI in favor of API-based integrations, many carriers found themselves in a bind. Kleinschmidt stepped up to the plate, creating a repeatable process for their customers to transform carriers' existing data into API-compatible formats.

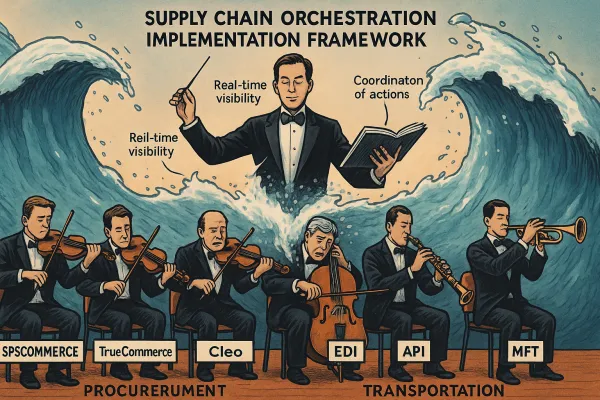

The solution isn't choosing between EDI and API. Often playing the role of the intermediary, freight brokers will stand a far better chance if their TMS systems utilize both API and EDI integrations. In doing so, they will make the best use of both worlds, API being the interface and EDI providing an engine.

Smart shippers use both. Big players, especially large retailers and major organizations, still rely on it for key transportation tasks. These include sending load tenders, updating statuses, and handling invoices, while API, or Application Programming Interface, is the next step in the evolution of trucking tech. APIs let you automate almost any action that someone could do manually in software.

The European landscape complicates this further. Solutions from Cargoson, MercuryGate/Infios, and Descartes now compete against regional specialists like Alpega and Transporeon for carriers requiring both integration methods across different operational contexts.

The Complete TMS Vendor Evaluation Framework for Integration Capabilities

Your vendor evaluation framework needs six integration assessment criteria that most RFPs overlook:

Real-Time Integration Architecture Analysis: Don't accept vendor promises about "supported integrations." Cargoson builds true API/EDI connections with carriers, not just accounts in software or standardized EDI messages that carriers must implement themselves. Test live connections during vendor demonstrations. Many vendors list carrier names without functional integrations.

Carrier Network Compatibility Mapping: Alpega TMS is connected to 80,000+ transport professionals across Europe. In 2025, they launched Alpega MultiParcel which also connects to over 1,000 parcel carriers. However, connection counts don't guarantee functionality. Map your specific carrier requirements against actual working integrations, not marketing numbers.

Hybrid Communication Protocol Testing: Whether it's EDI, API, or hybrid systems, this partnership makes compliance effortless. Your evaluation must test both EDI and API communications with the same carrier to verify seamless failover capabilities.

European Compliance Verification: Consider core TMS functionality from your primary vendor with specialized modules (carbon tracking, customs management, carrier connectivity) from best-of-breed providers that integrate via APIs. Test eFTI compliance, e-CMR compatibility, and EU ETS reporting capabilities with your actual carrier network.

Beyond traditional feature comparisons, focus on vendors that handle both integration types seamlessly. Modern cloud-based shipping software connects directly with hundreds of carriers through pre-built API and EDI integrations. Instead of setting up separate technical connections with each transport provider, you get access to your whole carrier network through one platform.

AI-Powered Integration Assessment Criteria

The next layer of your evaluation framework addresses AI capabilities in integration management. Current and foreseeable AI use cases in EDI include automated trading partner onboarding, AI-assisted mapping, outlier detection, intelligent error resolution.

Test vendor AI capabilities with specific scenarios. It uses machine learning to identify and reconcile mapping discrepancies, reducing the manual effort required to manage trading partner relationships and cutting onboarding from weeks to minutes. Request demonstrations of AI-powered carrier onboarding with your actual carrier network requirements.

This matters more than vendor presentations suggest. AI and ML algorithms can examine many facts, including historical shipment records, real-time site visitor situations, weather patterns, or even motive force conduct, to offer superior analytics and predictive abilities. For example, AI-powered TMS can dynamically optimize routes in actual time.

Include AI assessment criteria in your vendor scoring framework. Vendors with mature AI integration capabilities, including those from Cargoson, Cleo, and newer solutions, demonstrate measurable reductions in manual integration maintenance and faster carrier onboarding times.

Regional Integration Requirements and Vendor Positioning

European TMS procurement demands different approaches than North American markets. Europe transportation management system market accounted for a share of 26.5% and generated revenue of USD 4 billion in 2025. Europe leads in sustainability-driven TMS adoption due to strict emissions regulations, carbon reporting mandates, and low-emission zone compliance.

The regulatory timeline creates procurement urgency. By 9 July 2027, the eFTI Regulation will apply in full, while starting 19 August 2025, all heavy-duty vehicles registered in the EU and operating in Member States other than their Member State of registration must be fitted with G2V2 devices. These aren't just compliance requirements—they're TMS vendor differentiation criteria.

For European shippers, this consolidation complicates an already complex vendor landscape. SAP TM dominates German operations, MercuryGate focuses heavily on North American markets, while Alpega and Cargoson compete more directly for cross-border European business. Regional specialization matters more than global scale for hybrid EDI-API integration success.

The consolidation impacts extend beyond vendor choice. Each acquisition reshuffles these regional strengths and may impact the specialized capabilities that originally drove vendor selection. Your framework must account for post-acquisition integration capabilities, not pre-acquisition promises.

Carrier Ecosystem Compatibility Testing

Here's the procurement reality most teams ignore: Consider the integration challenges: 66% of technology projects end in partial or total failure, with 17% of large IT projects threatening company existence. Your carrier compatibility testing must prevent joining these statistics.

When your TMS vendor becomes an acquisition target, you inherit these integration risks without directly managing the project. Test actual carrier connections during vendor evaluation, not just integration promises. Many vendors demonstrate connections that require months of custom development for European carrier networks.

Develop a carrier ecosystem test that includes your top 10 carriers across different transport modes. Test both EDI and API connections for the same carriers where possible. Some TMS providers like Cargoson will integrate any carrier for you, for free (while others charge you for that and make you wait months or years).

Your testing methodology should verify real-time data exchange, not just initial connectivity. Many integrations work for basic booking but fail during tracking updates, invoice processing, or exception handling. Test complete transaction cycles with actual shipment data.

Implementation Risk Mitigation Strategy

Multi-vendor strategies can provide insurance against individual vendor risks, though they require more complex integration management. Consider core TMS functionality from your primary vendor with specialized modules (carbon tracking, customs management, carrier connectivity) from best-of-breed providers that integrate via APIs.

Your implementation timeline should account for hybrid integration complexity. Cloud-based TMS implementation typically takes 1-4 weeks compared to 6-18 months for traditional on-premise systems. Solutions like Cargoson can have shippers managing freight within days of signing up. However, these timelines apply to standard configurations, not hybrid EDI-API carrier networks.

Build implementation phases that test integration capabilities incrementally:

Phase 1: API-First Carrier Testing - Start with carriers offering robust API capabilities. This validates your TMS platform's API integration framework before adding EDI complexity.

Phase 2: EDI Legacy Integration - Add EDI-only carriers after API foundations prove stable. Many implementation failures occur when teams attempt simultaneous EDI and API rollouts.

Phase 3: Hybrid Carrier Validation - Test carriers requiring both integration methods for different transaction types. This often reveals platform limitations not apparent in single-integration scenarios.

Phase 4: Exception Scenario Testing - Validate platform performance during integration failures, carrier system outages, and data format changes. These scenarios expose vendor support capabilities and platform resilience.

Contract protection becomes essential during consolidation periods. Maintain qualified backup vendors throughout your contract period. The competitive landscape includes established players like Manhattan Active and FreightPOP alongside specialists like Alpega and Cargoson.

Future-Proofing Your TMS Investment Decision

Your 2025 strategy should focus on platforms that handle both integration types seamlessly. Cargoson TMS has emerged as a leading player in the field, setting new standards in transport management. Their cutting-edge software is designed to simplify and streamline logistics operations, alongside solutions from MercuryGate and Descartes that are evolving to support unified hybrid approaches.

The technology landscape favors unified platforms over point solutions. Regardless of which route a transportation company takes when choosing between EDI, API or using both across different customers, setting them up and executing maintenance and updates can be a challenge. Choosing a TMS partner that is well-versed in both will be essential for both carriers and brokers.

Your decision framework should weight vendor capabilities in handling integration complexity rather than just feature counts. Deep domain expertise in either will best ensure integrating with customers or partners is optimized to securely support data exchange that will always be simple, reliable and transparent.

Consider total cost of ownership beyond initial licensing. A cloud-based TMS typically costs between €200-€1000 per month for mid-sized companies, scaling based on shipment volume and features needed. Cloud-based TMS pricing models include monthly subscriptions that get rid of large upfront investments. Conventional systems might cost €100,000+ annually.

The consolidation wave creates opportunities for buyers willing to act decisively. Companies that understand the new landscape, evaluate vendors based on post-consolidation criteria, and implement with appropriate risk mitigation will emerge with competitive advantages. Your TMS vendor selection decision in 2026 determines whether you join the 73% experiencing implementation challenges or the minority achieving transformational logistics improvements.

Start your evaluation with integration capabilities, not feature lists. Test actual carrier connections during vendor demonstrations. Build implementation timelines that account for hybrid complexity. The vendors available today may not exist independently tomorrow, but the integration capabilities you select will determine your logistics success for years ahead.